PiBot for Repetier Motherboard

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: working

| Description | Part of PiBot Electronics Motherboard

|

| License | |

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | see files

|

| External Link |

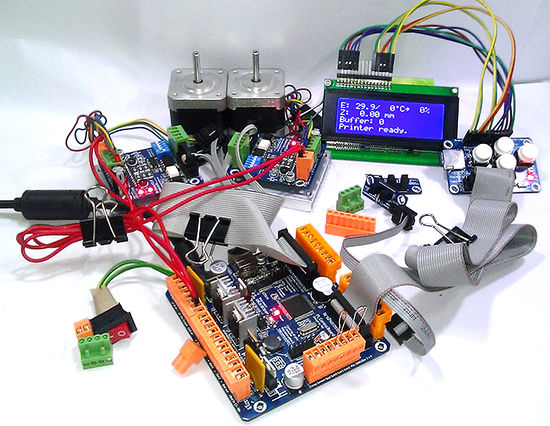

- PiBot for Repetier Motherboard is a part of PiBot electronics. It put forward a easy solution to make your 3D printer and CNC machine. Not only an electronic board, but also PiBot-box which with the function similar to computer Host and you can easily handle it only plug few terminals.The technology of grit and black oxide finish dose used in PiBot-box fabrication.

Contents

Features & Specifications

Highlights

- PiBot-Box development kit Supported. Offer a set of solution to your electronics. Easy use and transplant.

- IDC & HT-396 cold-pressed terminal,It means these anti-plug linker is very convenience,fast and reliable.

- build-in pins assignment silk in the Top Over layer. It more convenience to change or make your own assignment.

- Officially authorization to add the Repetier terms on the boards. Support all the function in the Repetier-Host and Repetier-Firmware.

- Compatible all of the pins in the Ardunio Mega 2560 and Ardunio ADK

- It's flexible! Capability to supply motors and heaters with a different voltage.

- The heat bed with independent power source and Self-recovered safety. With two MOSFET parallel solution that can driver more powerful heat bed(optional function, you can use the soldered MOSFET only).

- It's affordable! it fit to manufacture PiBot, RepRap, Mendel, CNC machine or to etch DIY.

- Heater driver with heat sink,compatible more powerful heated header.

Details

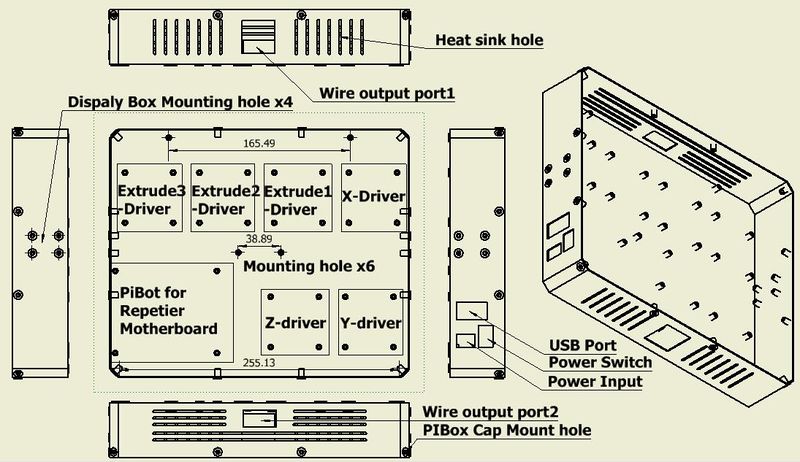

- PiBot-Box Size: 273*225*50mm Technology: Grit Technology,Black Oxide Finish Color/Colour: Matte Black Material: Code-Draw Steel

- Controller and motor drive discrete solutions.

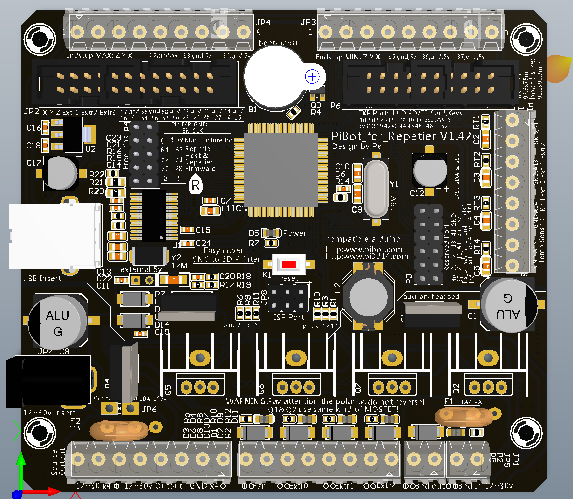

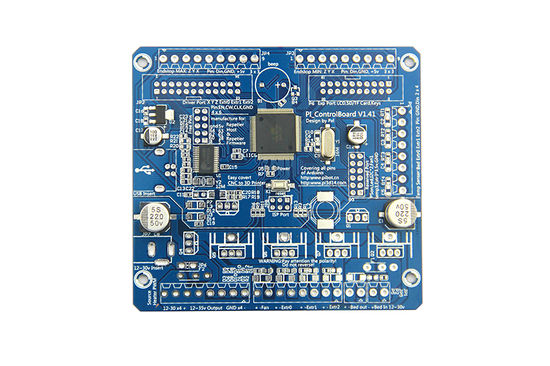

- Double-sided PCB. Board Size;99.9*91.2 mm-Rectangle ; mount hole distance; 92.6*75 mm-4xM3 hole

- CPU: ATmega2560, ATmega1280 (Atmel Corp.)

- 4x to 6x PiBot TB6600 Stepper Driver, exchangeable, up to 4.5A output and 45v input,adjustable microstepping. Using a IDC-24pin port, neat and dust-free finish.

- On-board USB-TTL converter.

- Integrated hardware for a fan, three extruder, a heated bed, 4 temperature sensor, 6 endstop port.

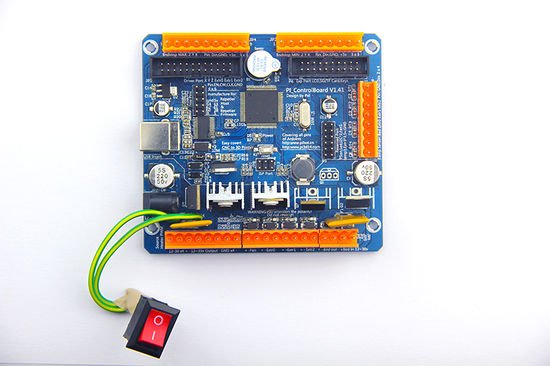

- External hand switch [120V-10A]

- IDC-20pin expand port, include: SD cards, keys, dispaly LCD (lcd1602 or lcd2004),reset button.

- Extension Boards for additional extruder, temperature sensor, fans, I2C bus device.

- Extraction free pins use for whatever is desireable.

- Single Supply, use the LM317File:LM317 for PiBot.pdf 3-terminal adjustable regulater, 5v supply solution. So the input can up to 40v.

Design Goals

- Designed for Repetier and PiBot-box.

- Offer an easy convert solution that to change your CNC machine into a 3D printer.

- Easy use for DIY enthusiast, convenience for secondary development.

- Support more extrude header and more types of machine.

- Make it similar to computer host and you can easily handle it only plug few cables.

- PiBot for Repetier Motherboard: http://www.pibot.com/index.php/pibot-for-repetier-motherboard.html#.UmNs17LBjVk

Communication & Contact

- Any idea to develop this motherboard, you can email Pan Xinlong.

- All parts are licensed under CC BY-NC-SA 3.0.

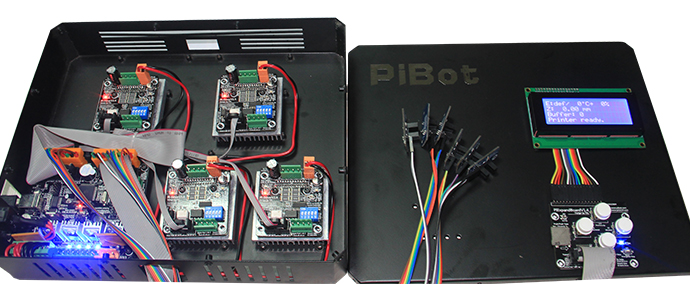

PiBot Box

PiBot Box _an Code-Drawn Steel Box. It can hold 1 PiBot mother Board , 4 PiBot TB6600 stepper driver, 1 manual controller board. This Steel Box include many heat sink holes which can continuous work for a few days without heat sink fan. Every working part contain the busy Indicator and this box with assorted machine hole.

The second generation will put forward later, it can include 6 PiBot TB6600 stepper driver.

Ports and Connectors

- PiBot_for_Repetier_Motherboard 3D PCB integrate

How to Build

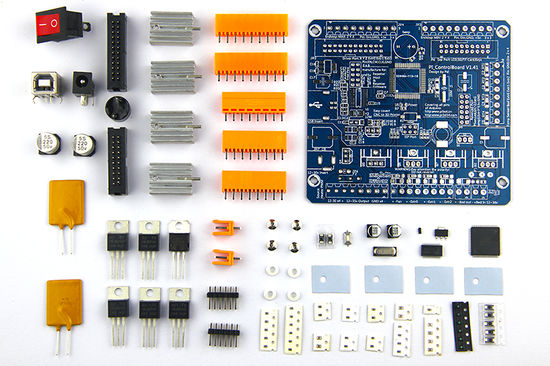

This part is only for users who want a empty PCB and weld them. The Mother board purchase from PiBot is welded by High-speed SMT machine in PCB process factory.

- Solder Images

- Prepare all of the components to build a PiBot For Repetier Mother Board;

- You'll need a soldering toolkit and SMT soldering toolkit to finish this board.

- Use SMT soldering toolkit

- Apply solder paste to every exposed SMD pad.

- Place each SMD component on its appropriate pad.

- Place populated board on a cold hotplate,turn hotplate on,board solders itself!

- Solder in remaining through hole components.

- If you without a soldering toolkit, you can also use an tweezers and an soldering iron finish them by manual. All of them are hand solderable!

- Use soldering toolkit

- Insert through hole components.

- solder all these pins to the pad.

IDC-20pin expand connector,IDC cold compression pincers

HT-396 cold-pressed terminal,HT cold compression pincers

- Hardware Test & Debug

- Before plug in the power source and USB cable, you need to check the polarity of electrolytic capacitor, chip and diode.

- Use an digital multimeter to test the resistance value of the power. Usually, it has a increase resister. Ensure no short cut and insufficient solder.

- If no problem, you can plug in the USB cable, the power LED (red) lighten.

- Plug in IDC-20pin expand connector,IDC-24pin Driver connector,temperature sensor.

- Now, you can open the Repetier Host, click "Connet".

- Notice

Firmware & Host

- PiBot for Repetier Motherboard V1.4 uses by default Repetier host and Repetier firmware.

- Download the Repetier firmware and Code editor Arduino IDE or Source Insight

- Unzip the Repetier firmware, open your Arduino IDE.

- Select the Board type "arduino mega 2560" in "Tools\Board\arduino mega 2560" and the "Serial Port" in "Tools\Serial Port\COM**"

- Open file Repetier.pde or "Repetier.ino" in "Repetier Unzip file\Repetier-Firmware\src\ArduinoAVR\Repetier\Repetier.pde" or "Repetier Unzip file\Repetier-Firmware\src\ArduinoAVR\Repetier\Repetier.ino".

- Select configuration.h set #define MOTHERBOARD 315 (PiBot for Repetier V1.4) or #define MOTHERBOARD '314 (PiBot for Repetier V1.0-1.3)

- set #define DRIVE_SYSTEM 0 (full cartesian system, xyz have seperate motors.) & #define FEATURE_CONTROLLER 8( PiBot Display/Controller extension with 20x4 character display) or #define FEATURE_CONTROLLER 9 (PiBot Display/Controller extension with 16x2 character display).

- Click the "Verify" button to compile the code or direct click "Upload" button to compile and upload firmware to PiBot for Repetier mother board.

- Other firmware maybe compatible too, but you need to configure it. Such as: Marlin firmware.

Troubleshooting

- If part of module can't work, you can easily deal with them by check the connect headers and the dip Resettable Fuse.

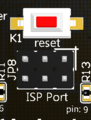

- If you can't upload the firmware, Please check the Aduino tools setting and press the "reset button" once the compile finished.

Safety Tip

Once you start putting electricity into your RepRap - even at just 12 volts - you have to take basic, common sense precautions to avoid fires. Just in case these fail, test your workshop smoke detector. Don't have a smoke detector? Get one!