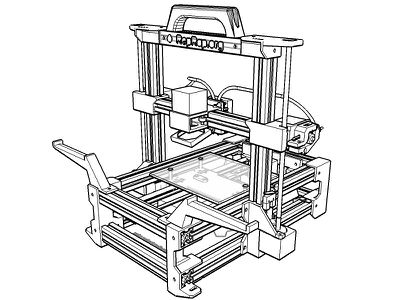

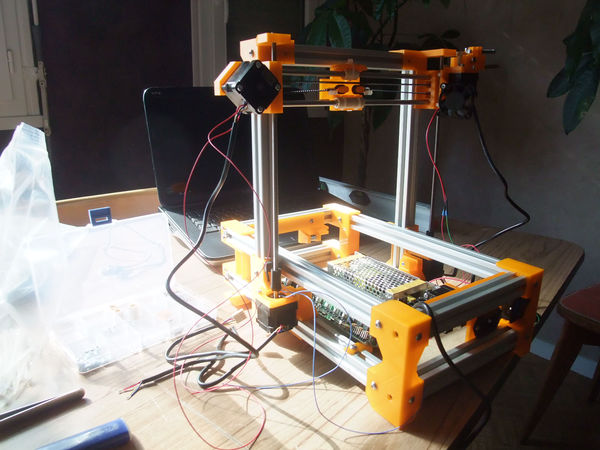

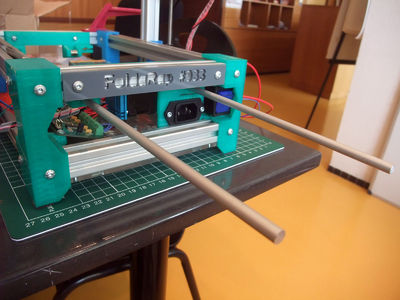

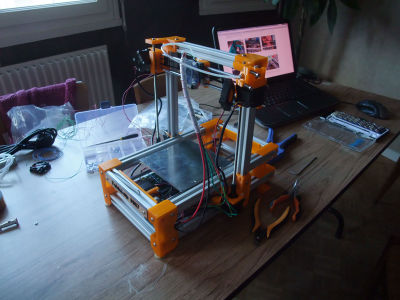

FoldaRap Build Manual

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Tools required

- 1,5 mm hexagonal wrench (for the pulleys grub screw)

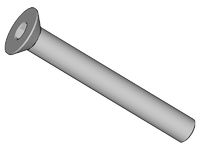

- 2 mm hexagonal wrench (for M3 counterksunk bolts and pneumatic fittings "MA-12-03-M5")

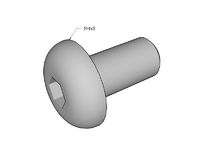

- 2,5 mm hexagonal wrench (for normal M3 cap-head bolts and the rounded M4 bolts used for the frame)

- little flat screwdriver (1,5mm) (for the board's screw terminals)

- Philips (PH2) or flat screwdriver (3mm) (for the psu's screw terminals)

You may need also :

- a 5,5mm flat spanner or a small pliers (for m3 nuts)

- something to cut wires, and strip them (knife, automatic striper, etc.)

- a lighter for the heat-shrink sleeves

- soldering iron (to eventually solder the endstops)

- small files (round, flat) to eventually ream the printed parts

- a glue gun (gluing the endstop on the printed part is easier/quicker than using bolts)

- a multimeter (to set the drivers current)

Contents

Previous Version

The build manual for the FoldaRap 1 is here.

General tips

- Read the whole manual once or twice before starting, to get an overview of the build

- Basically we have a main frame and several sub-assemblies, some can be done in parallel : gather your friends and establish a record for minimum building time ! (Actual best record : 4 hours)

- Work on a cutting mat if you have one, it will protect your table plus they often show a millimetre grid that will be useful to check the bolts length (with some experience you will recognize them just by looking or holding one).

- Place you mouse over a picture in a list if you wonder what part it is

- In case of doubt, don't hesitate to have a look at the 3d model in Sketchup (before/during the build), even if about a next version of the machine it will show you the folded/unfolded state of the machine and you can play around with it :)

Ok let's start It should take approximately 12 hours to put everything together. From step 1 to 4 : 2-4 hours

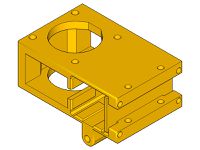

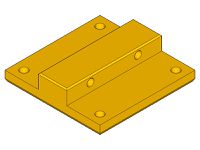

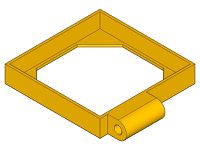

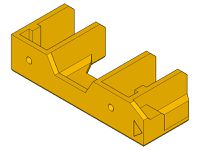

Know the parts

Firstly, have a look at all the part and learn what everything is.

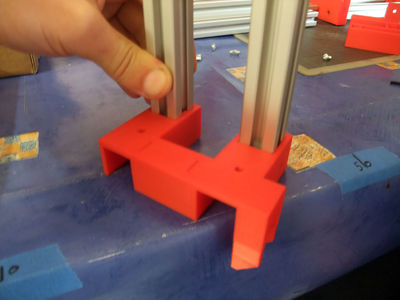

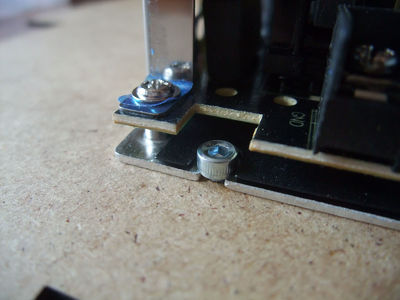

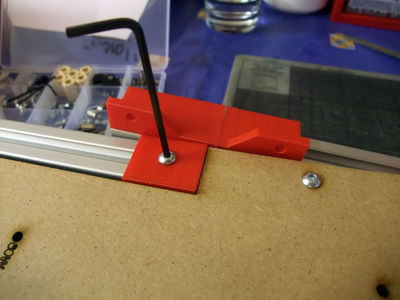

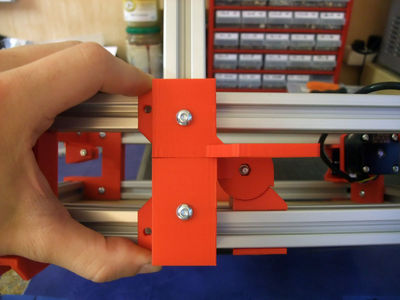

How to insert a T-nut

Tightening torque : 2.5 Nm (+/- 5%)

Tightening torque : 2.5 Nm (+/- 5%)

<videoflash>9CAiVmfO2mk|320|240</videoflash>

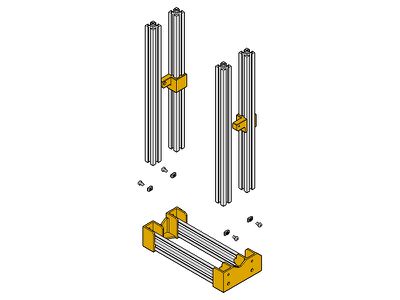

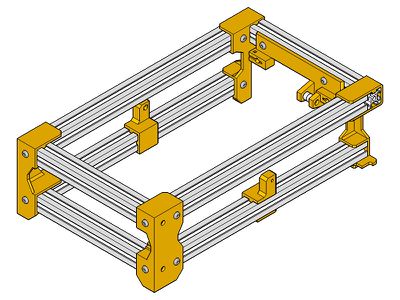

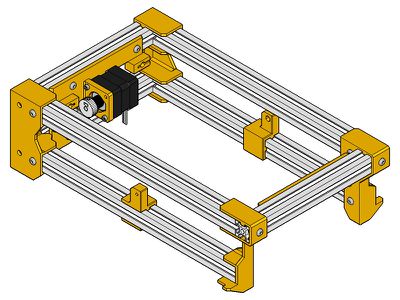

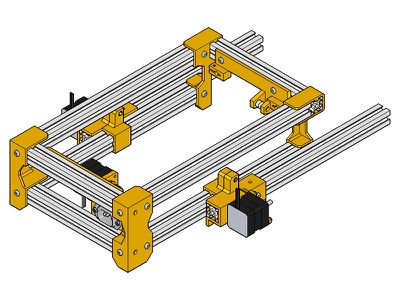

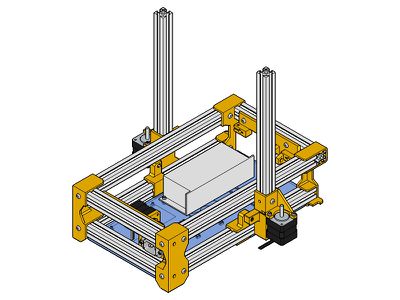

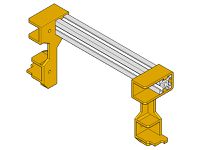

Base Frame

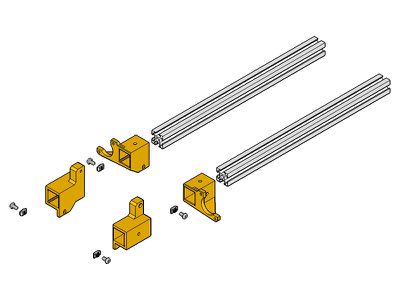

Rear Base

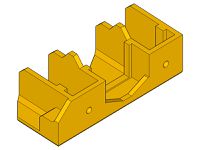

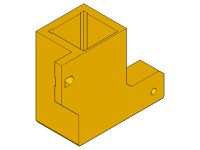

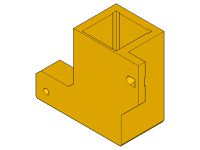

x1 foot-rear-left

x1 foot-rear-left

x1 foot-rear-right

x1 foot-rear-right

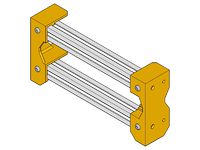

x2 200mm profile

x2 200mm profile

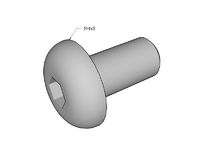

x4 m4x8

x4 m4x8

x4 t-nut

x4 t-nut

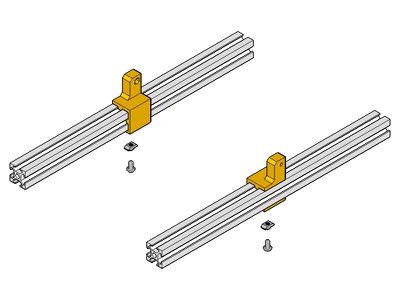

Front Base

x1 foot-front-left

x1 foot-front-left

x1 foot-front-right

x1 foot-front-right

x2 200mm profile

x2 200mm profile

x2 m4x8

x2 m4x8

x2 t-nut

x2 t-nut

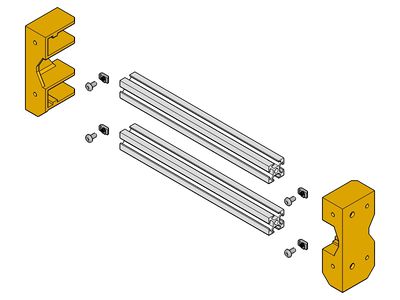

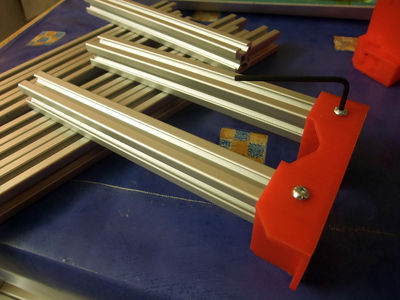

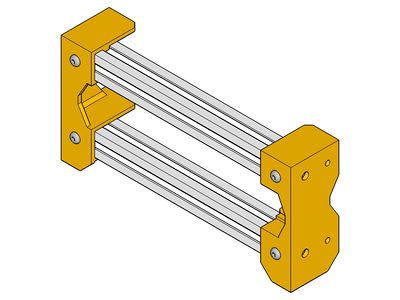

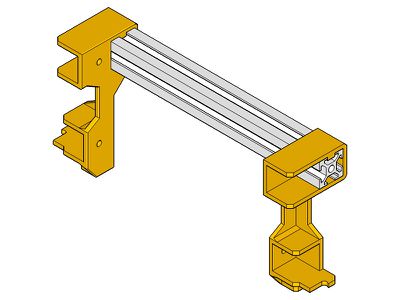

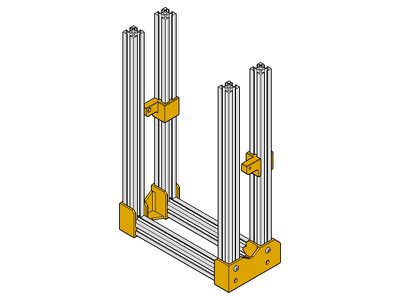

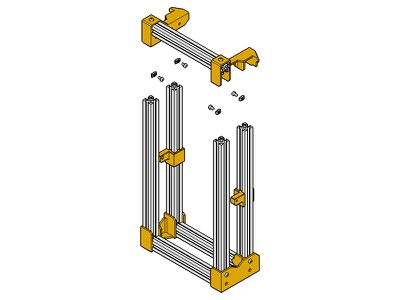

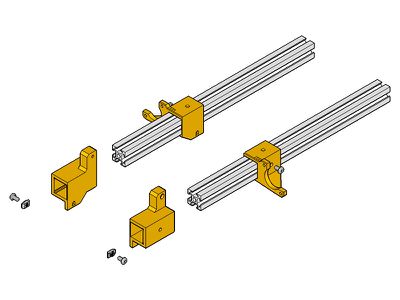

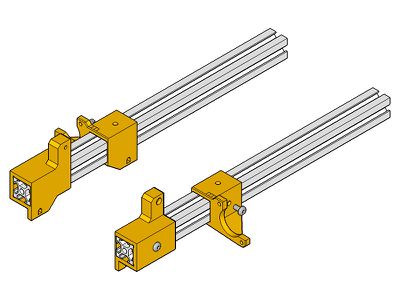

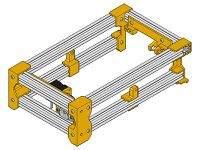

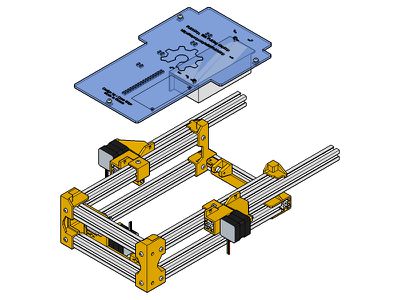

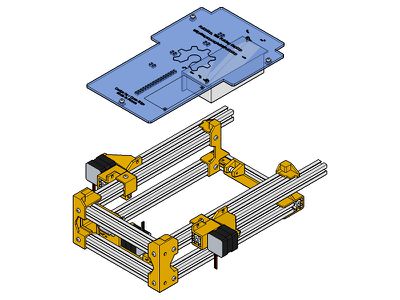

Base Frame

x1 rear assembly

x1 rear assembly

x1 front assembly

x1 front assembly

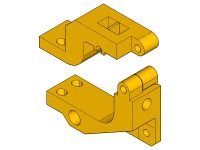

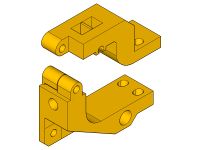

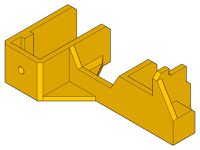

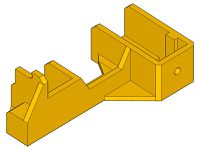

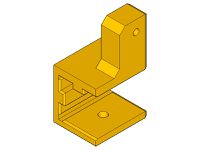

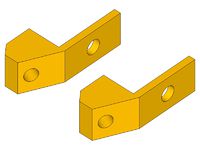

x1 hinge-inner-left

x1 hinge-inner-left

x1 hinge-inner-right

x1 hinge-inner-right

x4 300mm profile

x4 300mm profile

x10 m4x8

x10 m4x8

x10 t-nut

x10 t-nut

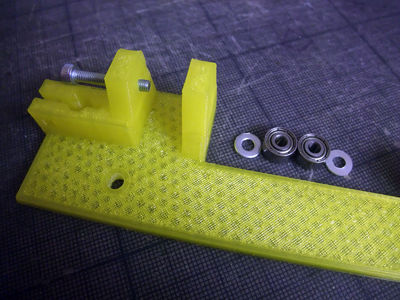

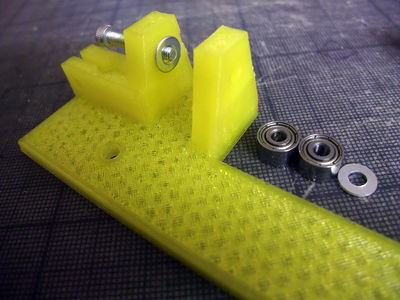

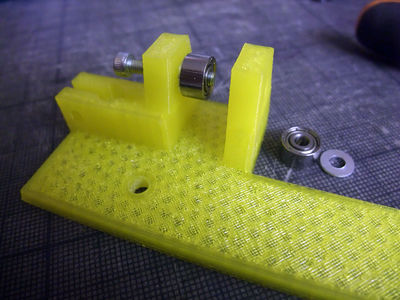

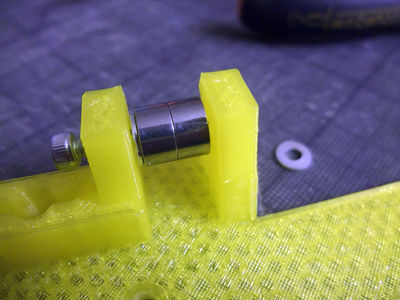

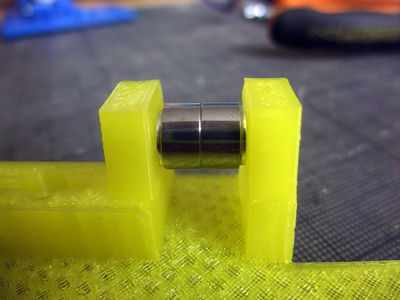

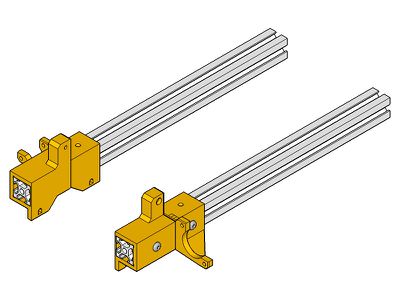

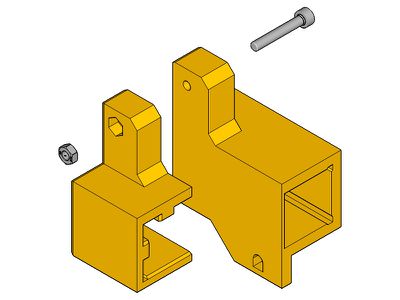

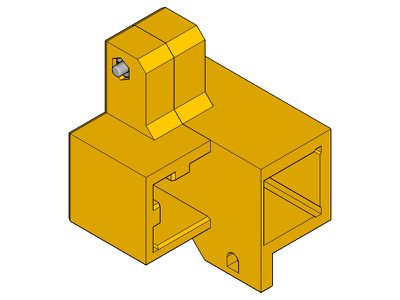

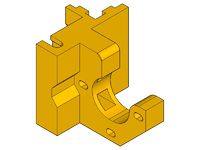

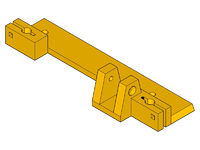

Y-idler

y-idler

y-idler

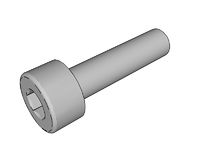

x1 m3x20

x1 m3x20

x2 603zz bearing

x2 603zz bearing

x2 m3 washer

x2 m3 washer

x2 m4x8

x2 m4x8

x2 t-nut

x2 t-nut

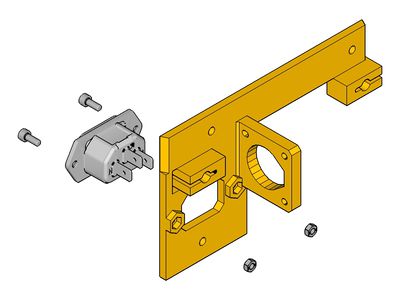

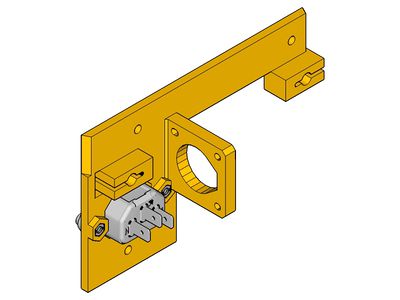

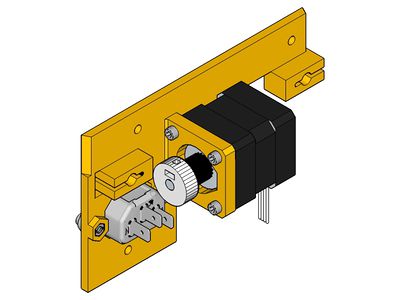

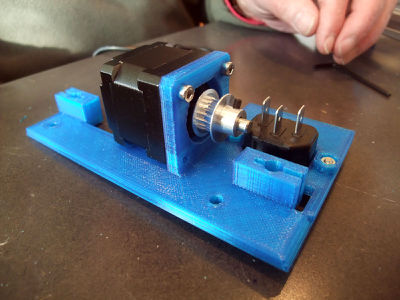

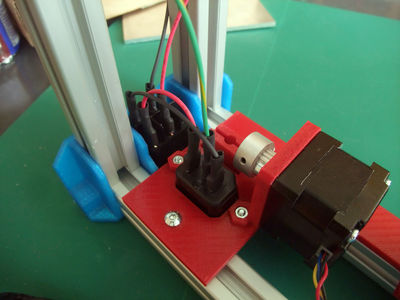

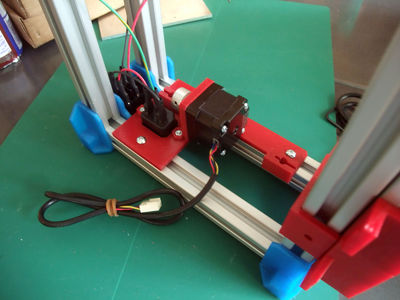

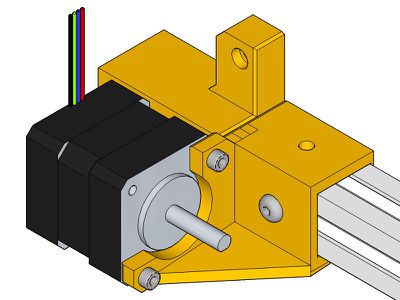

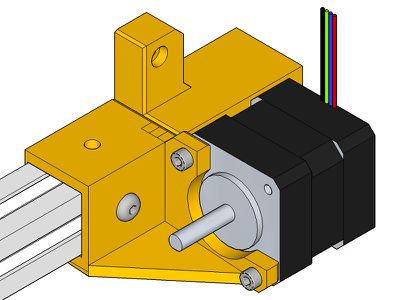

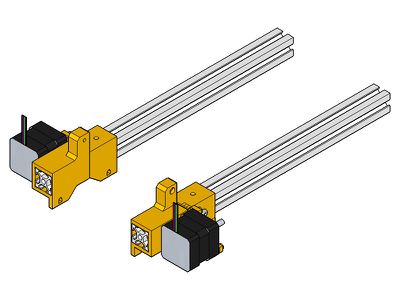

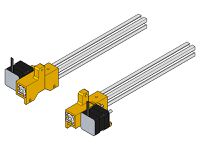

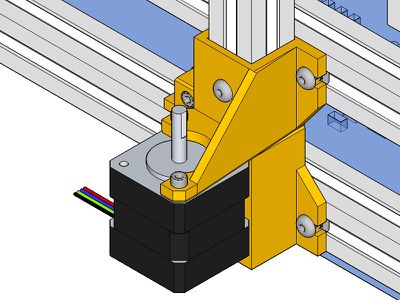

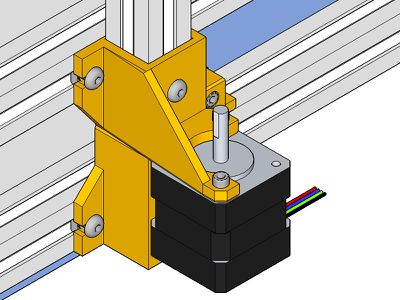

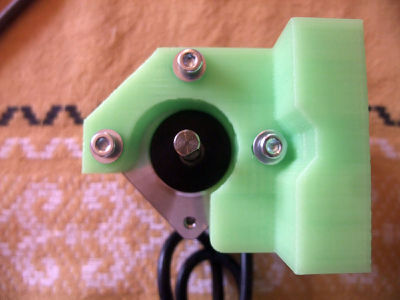

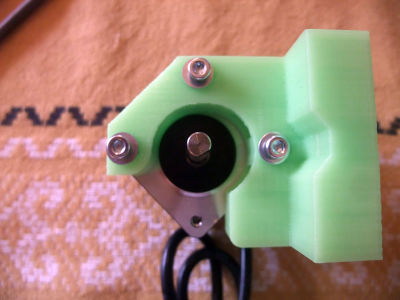

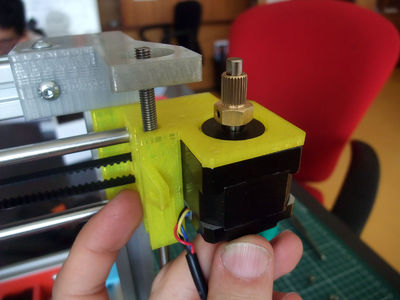

Y-motor

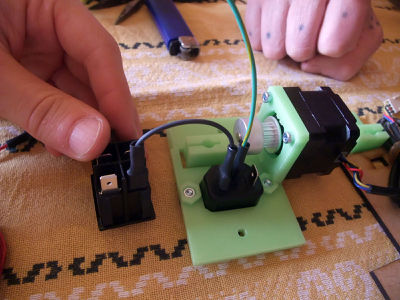

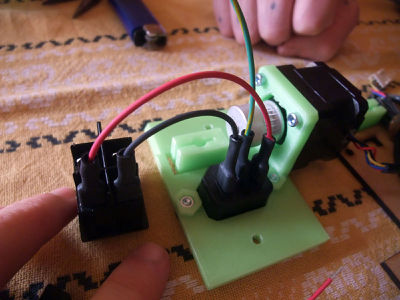

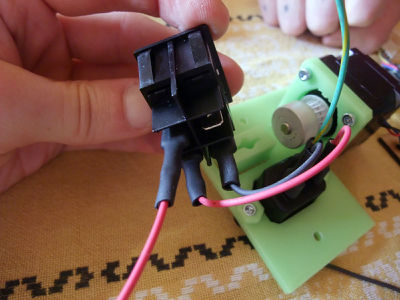

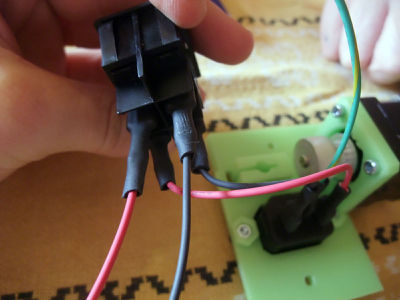

Plug

x1 y-motor

x1 y-motor

x1 plug

x1 plug

x2 m3 nut

x2 m3 nut

x2 m3x8

x2 m3x8

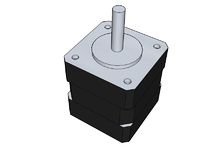

Motor

x2 m3x8

x2 m3x8

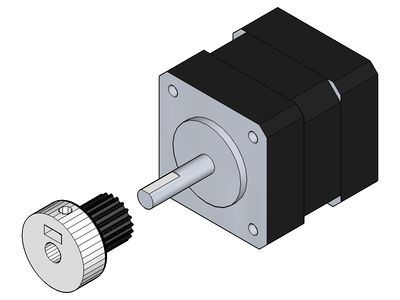

x1 nema 14 stepper motor

x1 nema 14 stepper motor

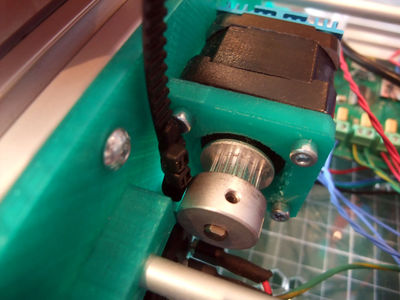

x1 pulley

x1 pulley

Wiring

x7 ferules

x7 ferules

heat-shrink sleeve

heat-shrink sleeve

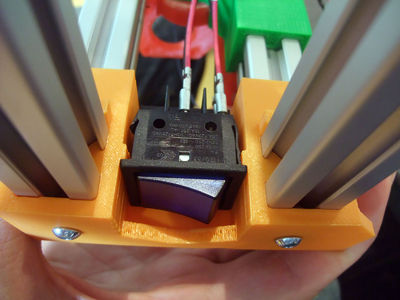

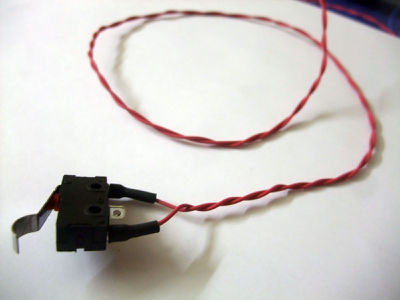

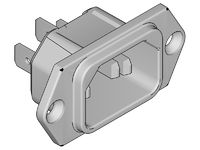

x1 switch

x1 switch

x3 m4x8

x3 m4x8

x3 t-nut

x3 t-nut

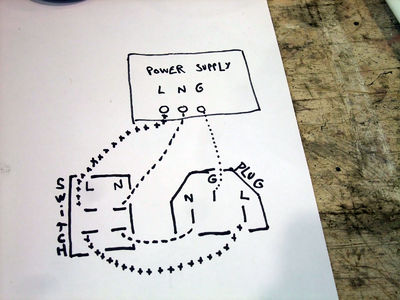

1 red and 1 black wire 18AWG of 10cm, one end with ferule, the other end just stripped (blue-switch Live/Neutral to power supply Live/Neutral). You may need longer wires depending of the power supply and it's position on the underplate, it may be good to shorten them later, once the psu is in place.

A part of the wiring depend of the combination of electronic board and power supply, for other version : FoldaRap_power-supplies

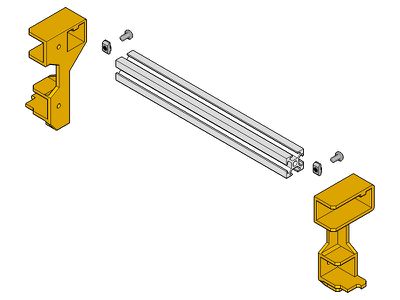

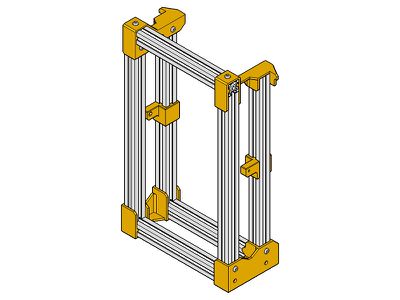

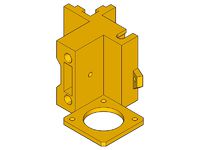

Z-axis

Z-Left / Z-Right

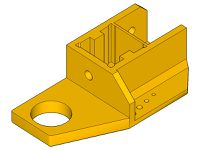

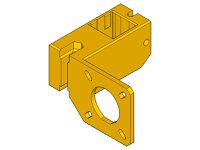

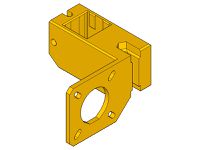

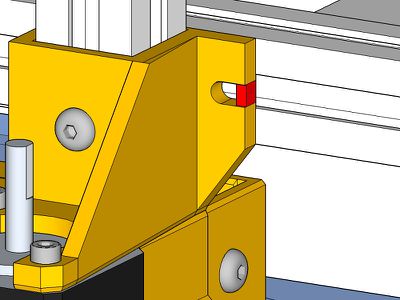

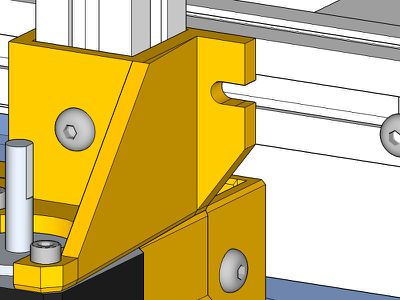

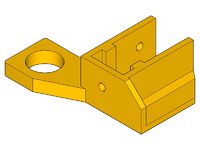

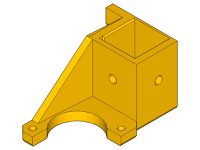

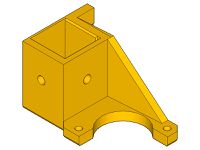

x1 hinge-outer-left

x1 hinge-outer-left

x1 hinge-outer-right

x1 hinge-outer-right

x1 z-motor-left

x1 z-motor-left

x1 z-motor-right

x1 z-motor-right

x2 300mm profile

x2 300mm profile

x4 m4x8

x4 m4x8

x4 t-nut

x4 t-nut

Z-Motors

Hinges

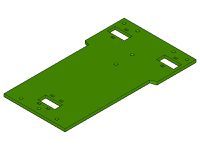

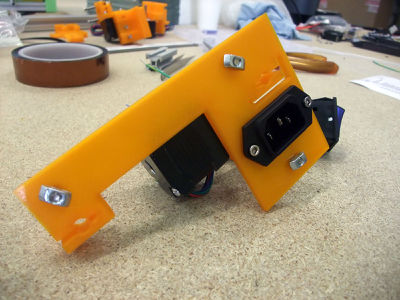

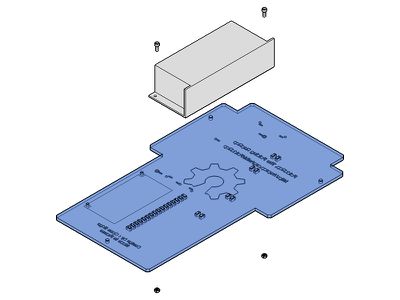

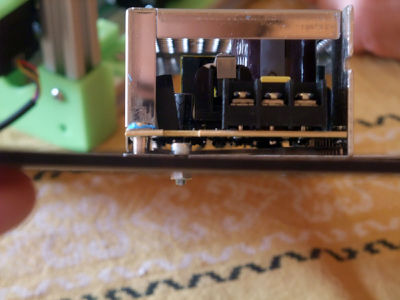

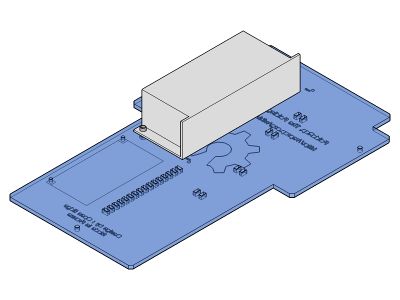

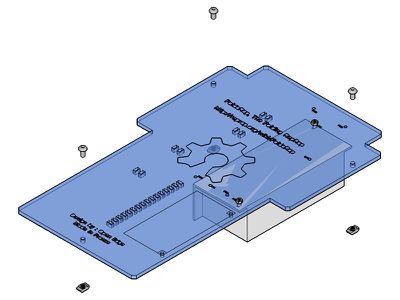

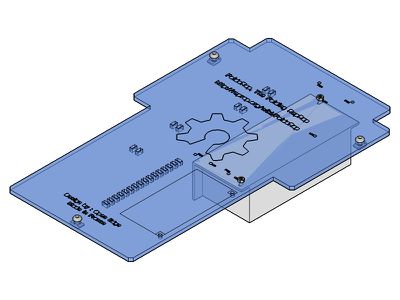

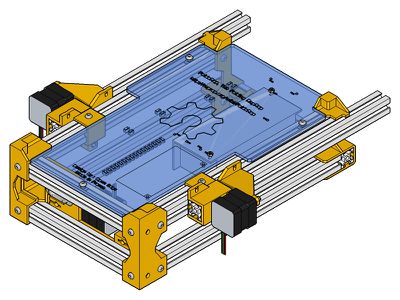

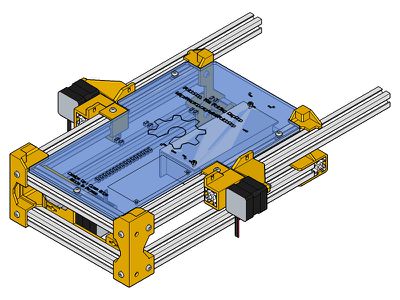

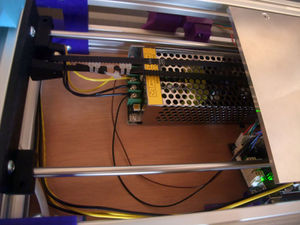

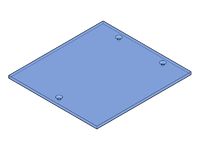

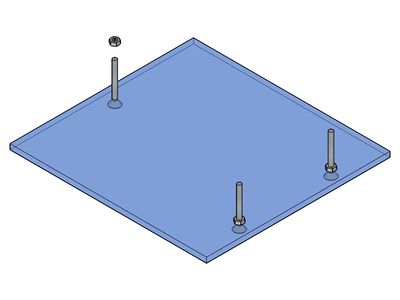

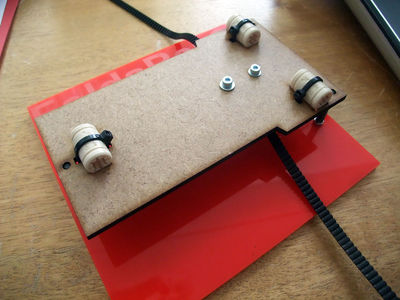

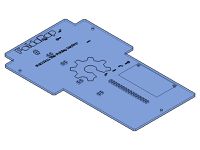

Underplate

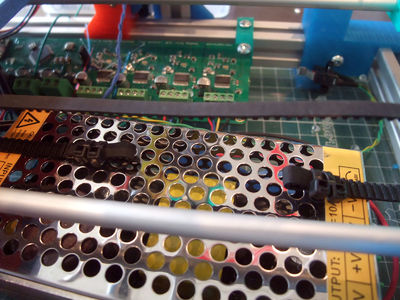

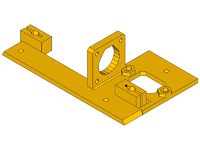

Power Supply

Different kind of power supply have been used in FoldaRap builds, if you don't recognize yours look at this page : FoldaRap power-supplies

Anyway, the principle is always 1) bolt the power supply on the plate, 2) then the plate on the base of the frame

x1 power supply

x1 power supply

x2 m3x8

x2 m3x8

x2 m3 nut

x2 m3 nut

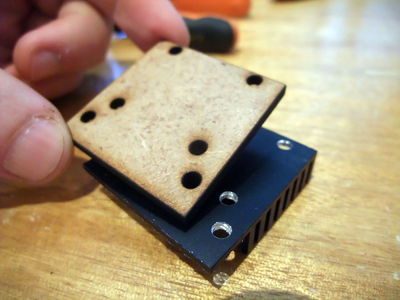

x1 lasercut underplate

x1 lasercut underplate

x6 m4x8

x6 m4x8

x6 t-nut

x6 t-nut

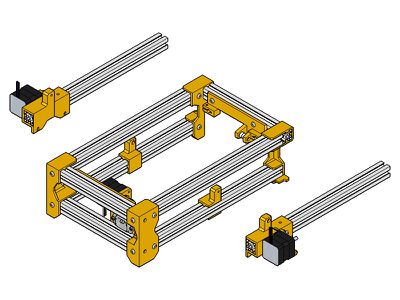

Z-axis 2

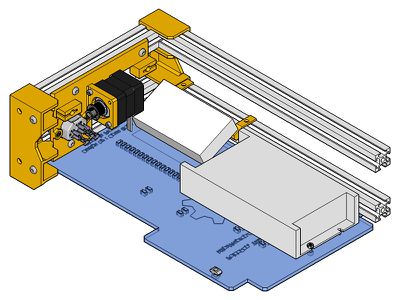

X-axis

X-motor

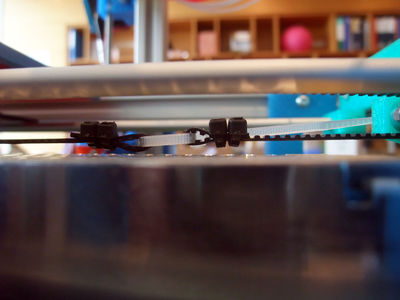

The holes for mounting the motor are wide in order to be able to use them for adding tension on the X belt. Thus mount the motor as close as possible to the extrusion side in order to be able to push the motor the other way arround at the tensionning step.

x1 (with 50cm red 26AWG wires for x-endstop, fix with an m3x8 or glue gun)

x1 (with 50cm red 26AWG wires for x-endstop, fix with an m3x8 or glue gun)

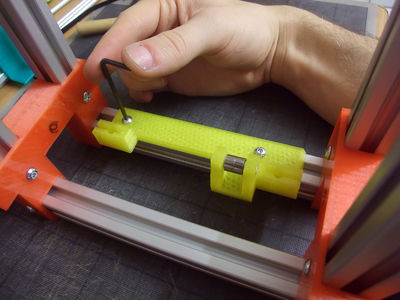

X-idler

After wiring, put the two x-ends in place (impregnate the printed parts with oil for better sliding) and add the smooth-rod without forgetting the three linear bearings.

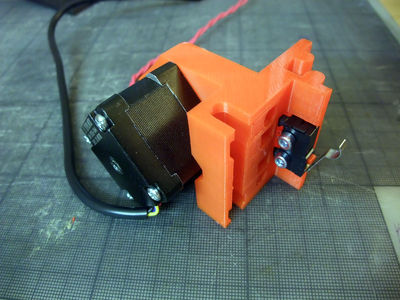

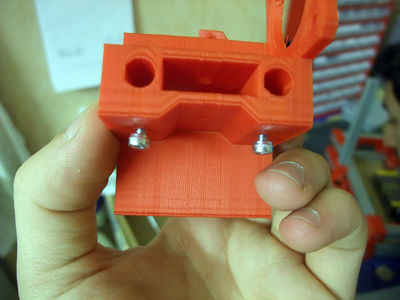

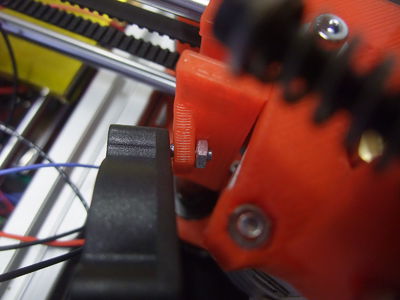

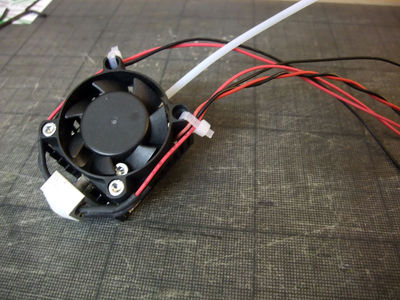

Extruder-fan

(Optional)

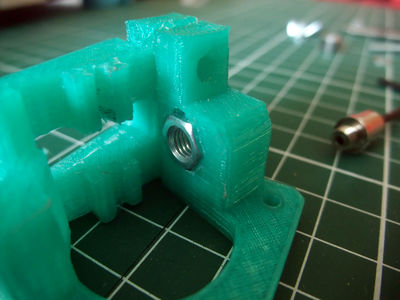

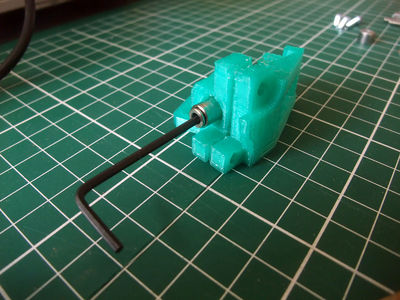

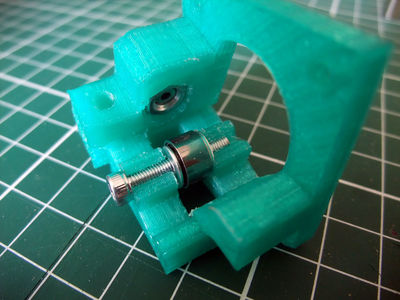

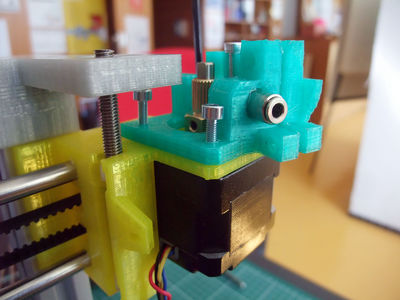

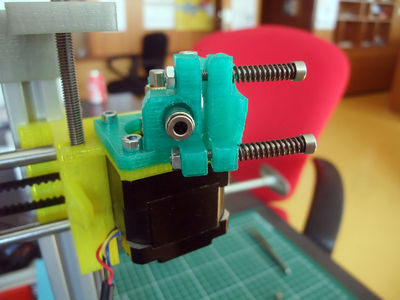

Extruder-idler

For previous version using a geared PG35L see FoldaRap_PG35L

x1 Nema14 (50cm)

x1 Nema14 (50cm)

x3

x3

x1 (just one)

x1 (just one)

Top-frame

<videoflash>xOSs5n_cQY4|320|240</videoflash>

X-carriage

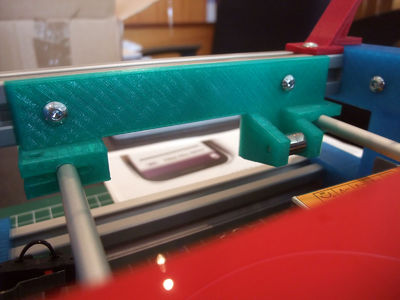

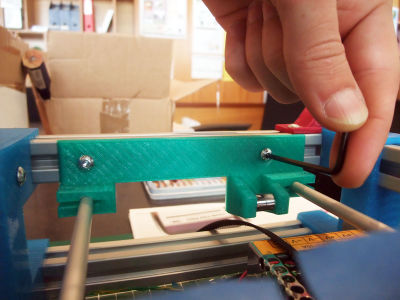

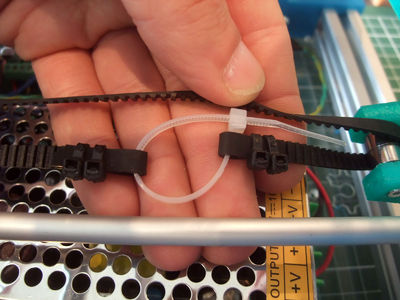

x1 (700mm, longest of the two belts)

x1 (700mm, longest of the two belts)

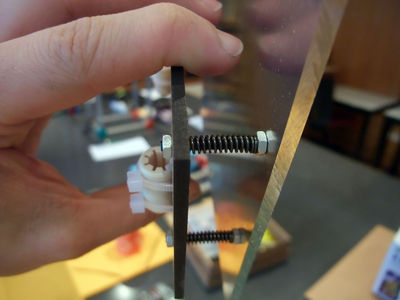

Z-rods

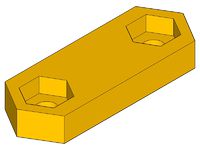

x4 M5 nylon nut

x4 M5 nylon nut

x2 M5 threaded rod

x2 M5 threaded rod

<videoflash>iZKFV5miQEk|320|240</videoflash>

Great ! You are almost done !

Have a pause, you need to be relaxed for the next step, or you can also just head to the end :)

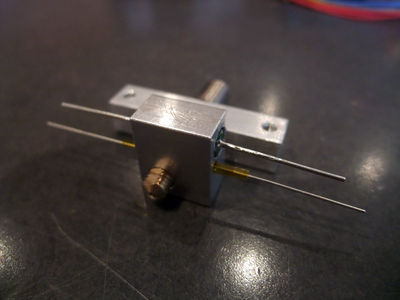

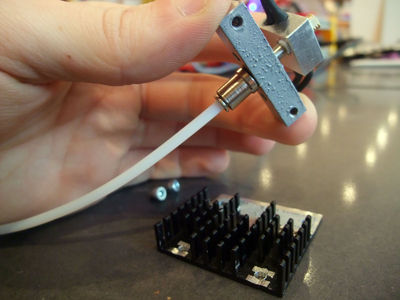

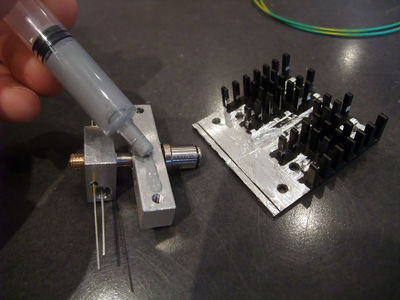

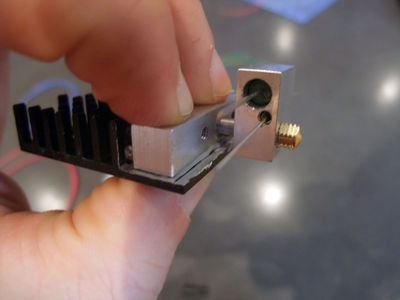

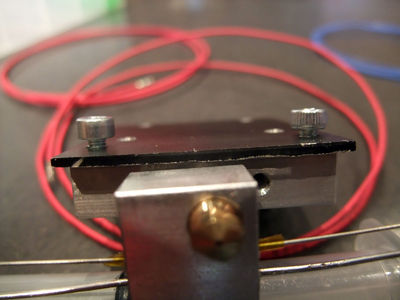

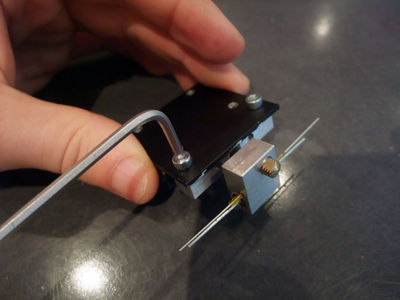

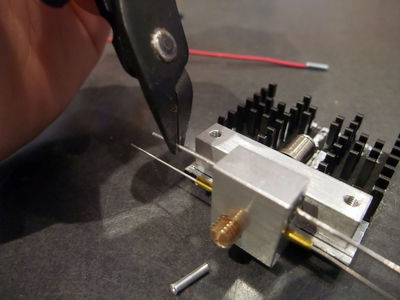

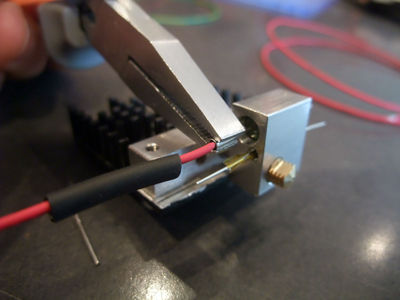

Hotend

x1 pneumatic-fitting

x1 pneumatic-fitting

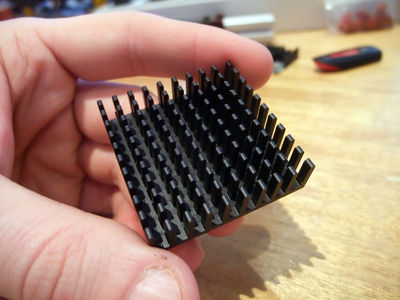

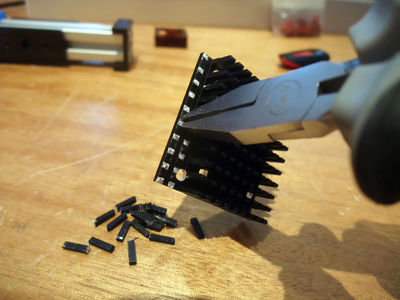

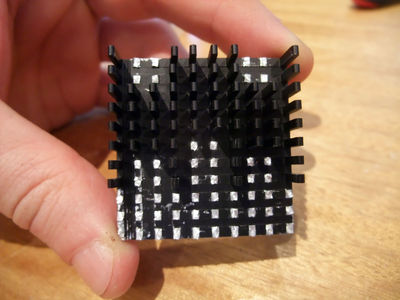

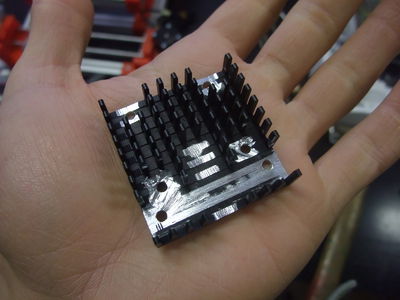

x1 heatsink-block

x1 heatsink-block

- cartridge heater

- thermistor 70cm 26awg

- fan prolongated to match 70cm

- see also the emaker huxley hotend

- don't forget to tighten the hotend while being heated to 200°C (later, once you will have wired everying on the electronic board)

- You may need to add a nut to each bolt if spacing is needed between the heatsink and the linear bearings

<videoflash>yqNI2H22ZcY|320|240</videoflash>

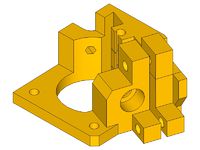

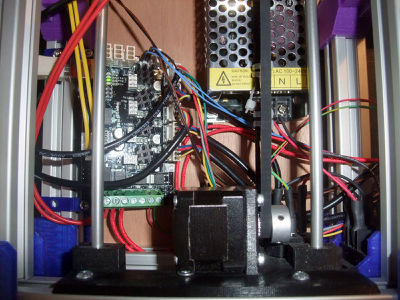

Electronic Board

Previous instructions for the AzteegX1 / Melzi

x1

x1

x1 board-mount

x1 board-mount

x2 m3x8

x2 m3x8

x2 m4x8

x2 m4x8

x2 t-nut

x2 t-nut

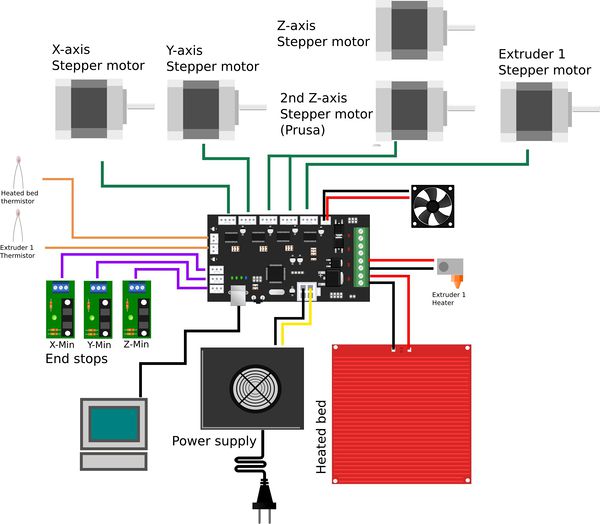

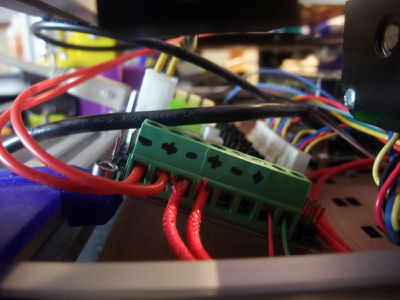

Wiring

Now lets plug everything to the board !

The Minitronics_10 page is well documented and the wiring should be quite easy with the molex connectors.

- It seems to use the same voltage reference as for a pololu (so we need to tune them to 0.4V, 0.45V)

Order/lenght :

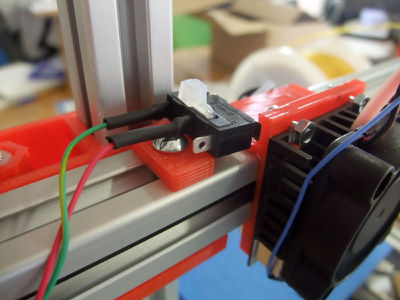

Endstops

x3

x3

x1 m4x8

x1 m4x8

x1 t-nut

x1 t-nut

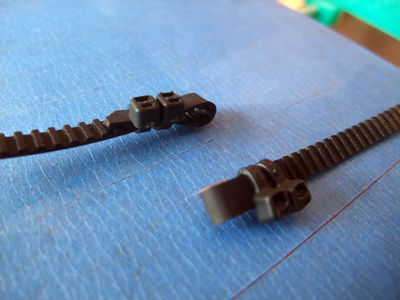

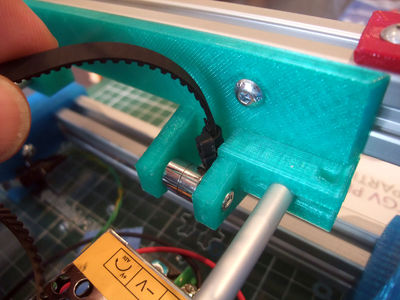

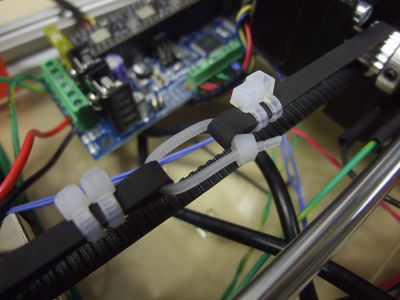

x2 zip-tie

x2 zip-tie

(with 25cm blue wires for z-endstop, fix with an m3x8 or simply use a glue gun)

Motors

- Y-motor

- Z-motors

- X-motor

- Extruder-motor

Hotend(s)

- thermistor (blue 70cm)

- heater (red 70cm)

Fans

- hotend fan (red/black 60cm) : on the fan connector of the board or directly on the psu

- (optional) extruder-stepper fan: same

- (optional) printed-part cooling fan: on the "cooling fan" screw terminal (turned on by sending Mcode "M106 Sxxx" (xxx being between 0 and 255), turned off by "M107" but Slic3r automate this)

Bed

Finish by this one, as it is moving, the wires need to be above all the other wires.

- thermistor (blue 35cm)

- peltier

Tidying

- spiral wrapping band : for the wires that came out of the base (30cm left / 60cm right).

(image)

Y-axis

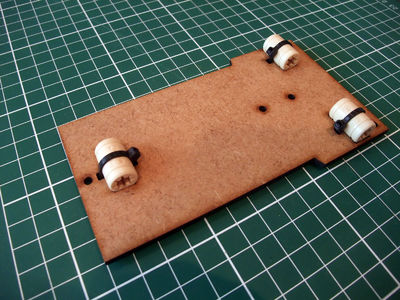

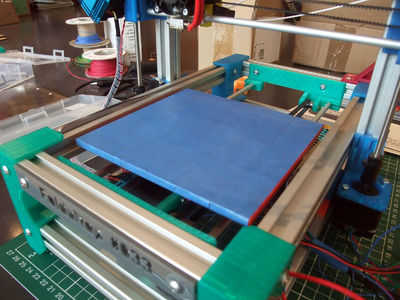

Bed-plate

If you have an aluminium heated bed look at this page : FoldaRap_Heated-Bed

Y-carriage

Other versions : FoldaRap1.0_y-carriage

Y-axis

x2

x2

x1 (with 32cm green wires for y-endstop)

x1 (with 32cm green wires for y-endstop)

x6

x6

Tighten the belt by closing the loops with zip-ties, then trim everything (video of belt tensioning [1])

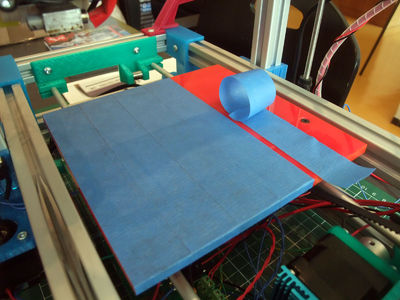

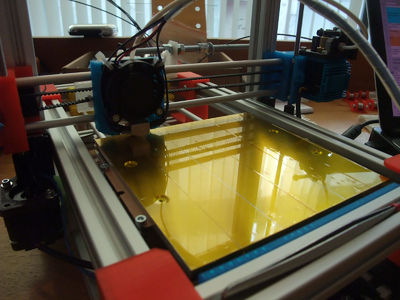

Tape (5-10 min)

Once the Y-axis is fitted it's easier to apply kapton (polyimide) or blue tape (outside masking tape, uv resistant and with acrylic adhesive)

<videoflash>MdCMMt7siy4|320|240</videoflash>

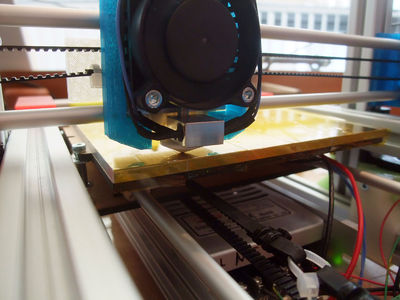

Leveling the bed and zeroing

The Z-zero is made when leveling the bed.

- Start by roughly leveling it

- then move the nozzle to the lowest point

- and adjust the 3 screws to level it regarding that height (by turning them until the homing move stop lowering the bed)

- repeat on each corners so the zero is exactly when the nozzle stop touching the bed (true for the four corners+center)

- I like to start with the X direction at the right bolt, then with the two at the left

<videoflash>35Xv_R8U_hU|320|240</videoflash>

Here is a video to show what I mean by "the homing move stop lowering the bed"

<videoflash>rjIMmzltyLQ|320|240</videoflash>

"Bad" (the bolts need to be tightened)

- Once the plan is set from left to right you can check front/end

- after that it's supposed to be leveled but may need few more tweaking for the right corners

Software side

- Skeinforge : you will only have to add a little offset (altitude), to have the desired height for the first layer, usually the same as your layer height.

- Slic3r : leave z-offset at 0, it will add one layer height automatically (you still may have to adjust it slightly to fine tune the Z-zero, depending on where your endstop have been glued).

Another advantage of that : by moving to the center of the bed from the zero height, the nozzle is also wiped by the side of the bed from any purged plastic ;-)

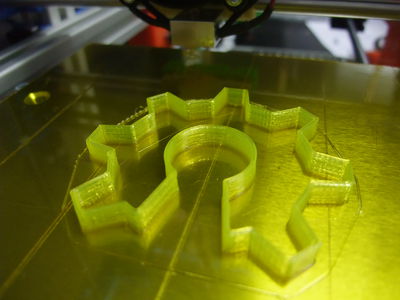

Go go go first print !!!

This article will probably help you along your first print :)

http://www.sarfata.org/3d-printing/2013/04/First-Steps-In-3D-Printing-With-Foldarap/

Also have a look at the User Manual