RepRapPro Huxley heatbed assembly

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Introduction | Frame assembly | Y axis assembly | X axis assembly | Z axis assembly | Heated bed assembly | Extruder drive assembly | Hot end assembly | Wiring | Commissioning | Printing | Maintenance | Troubleshooting | Improvements

| A notice about these instructions! |

|

These instructions are open to editing by everyone and anyone. |

Contents

Goal

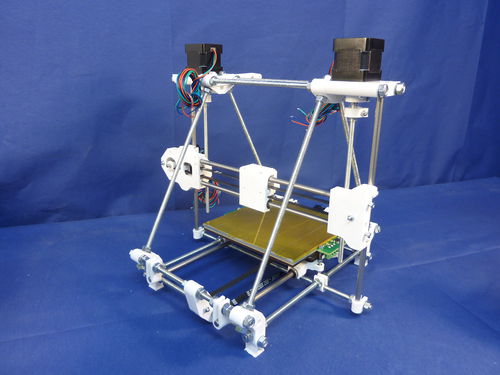

By the end of this stage, your machine will look like this:

See also this wiki page.

Tools

- Wire cutters

- Soldering iron

- Allen key

Heated bed assembly

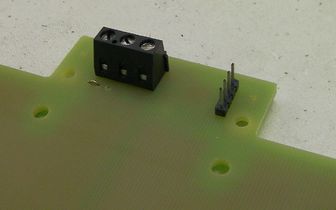

Start by soldering the connectors in place. The wire holes on the screw connector face outwards. Also use a length of wire to make a jumper between the left two holes beside the 3-way screw connector. Be particularly careful when soldering the large connector. You need to ensure that there is no dry joint and that there is a reasonable, although no excessive, amount of solder. This connector has to take quite a high current.

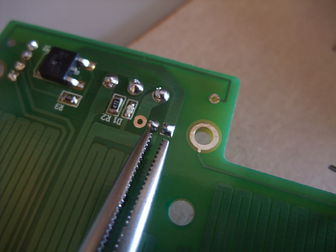

Take care when sandwiching the parts together that the edge of the recess does not hit the thermistor - you don't want to knock it off... NOTE : The thermistor should be electrically insulated from the aluminium plate. This can be achieved using a small piece of Kapton tape, or even a short length of PTFE plumber's tape over the thermistor.

Now may be a good time to consider applying Kapton tape to the surface of the printer bed.

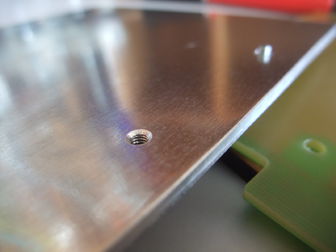

Put washers under the heads of the four short M3 screws and screw them through the stack to hold it together. Don't do the screws up so tight that they project through the aluminium plate. The ends of the screws need to be just below the plane of the top of the plate. If they project, put extra washers under their heads.

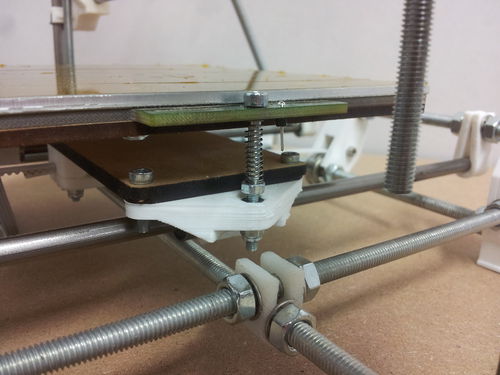

Put the long screws through the holes in the PCB, put on washers, drop the springs onto them, put on three more washers (one per screw), and put the M3 nuts on by about 10mm to hold the springs.

Use the screws to attach the heated bed to the machine. Screw the screws into the nylock nuts until the bed is secure and roughly level. Then loosely run the nuts down the screws (relaxing the springs) until they meet the printed parts of the Y sled. Tighten them gently against the sled.

(To level the bed accurately later, you will slacken those nuts, adjust the screws in the nylocks, then tighten the nuts again.)

If you find that the springs are a bit weak (and so do not hold the PCB firmly up against the heads of the screws), simply add three extra nuts under the washers on the ends of the springs. Use the top nuts to set the spring compression, and the bottom ones independently to secure the bed.

You should be able to push the bed down easily with a finger, and it should spring smartly back up again to rest under the screw heads.

Carefully run the Y-axis back and forth by turning the toothed pulley on the Y motor by hand. Make sure that nothing hits anything.