User:Spiritdude

My name is Rene K. Mueller, got interested in RepRap a few years ago but didn't follow up as the first models were expensive and too complex to build and use - this changed and since about December 2011 got interested more thoroughly again, thanks to several Kickstarter projects, such as Printrbot.

Contributions

- MakiBox, wiki-page started and basic information (not my invention, just realized it wasn't in the wiki yet)

- trying to put some structure and compareable numbers for each RepRap:

- Printed vs Non-Printed Items (calculate a RepRapFactor)

- Printing-Size / Building Volume

- Material Cost (just the items)

- Cost (assembled)

- Precision (position/printing)

- Speed (position/printing)

Favourite RepRaps

High Building Complexity

- Mendel aka "Sells Mendel", classic (1x Z-axis motor), Z-axis is X/Y-way stabilized

Not recommended to build since simpler versions exist:

Medium Building Complexity

- Prusa Mendel, (2x Z-axis motors), printed parts massively simplified - quasi standard now

- DurbiePrusaMendel, further refined

- MendelMax, further refined

Low Building Complexity

- Printrbot, loosly based on Prusa Mendel, very simple, Z-axis in the open (one end fixated)

- Bukobot, alike Printrbot but with aluminium extrusions (very rigid) and Z-axis is X-way stabilized

- FoldaRap, with aluminium extrusions, Z-axis is X-way stabilized, foldable

All-In-One

- FoldaRap, power-supply & controller nicely integrated, speciality: foldable (easy to transport)

- MakiBox, case with power-supply, controller, all in a box, speciality: pellets to filament converter built-in (still in development)

Considerations

Rigidity

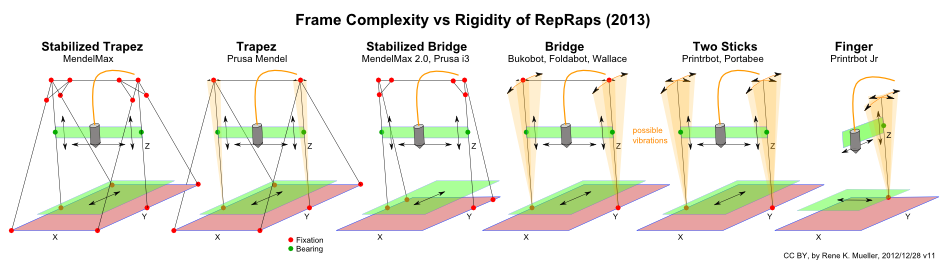

The Mendel based RepRap's are very rigid as the illustration shows, the MendelMax does best and triangulates the top pretty much, whereas the Prusa Mendel lacks one element so the top points are fairly triangulated and therefore stable - with slight possiblity to skew X-way and have vibration.

Bukobot and FoldaRap got rid off or let go some rigidity but tried (successful?) regain some of it by using aluminium extrusions instead of threaded rods like the Prusa Mendel - yet, from a geometric point of view that letting go complexity introduces Y-way vibrations, in particular Wallace which uses rods as framework, yet very appealing in its simplicity.

The other simple ones, like Printrbot and Portabee sacrifice the rigidity of the Z-axis by skipping the stabilization further: Z-axis is in the open (only one end fixated), possible source of vibration to X-way and Y-way, even though the printing head / bearing provide some X-way stability at the height. Therefore at higher Z-elevation Y-way and X-way vibrations may decrease the position and printing precision, in particular at high speed printing and heavier printing heads (e.g. multi extruders).

Ideally, the printing base is moved only Y-way (in case of these RepRaps considered here), but in real world will shake the entire construction - perceive the RepRap as a complex music instrument in vibration with its own resonance - any part which can vibrate will vibrate. It is therefore desired to reduce the "open ends" which likely will vibrate and triangulate them to maintain precision in position and printing at any point within the printing or building volume - and for obvious reasons: if framework is sufficiently rigid, permits to speed up the stepper motors further with little regards of mass of the extruder.

Quality Control

There are many factors regarding quality:

- linear printing integrity / structural skew (misaligned framework)

- framework rigidity (vibrations within framework)

- surface linearity (unevenness of material dispension, chosen slice height)

- resolution (testing what the limits of resolution are)

- material (printing gaps / bridges)

- etc

Q: How to measure easily quality (verifiable and quantitative)?

A:

- linear printing integrity

- simple and fast printing model which extends the entire building volume: quasi wireframe (minimal strut) cube: RepRap Benchmark: Linear Integrity

- framework rigidity

- simple and fast printing model which stresses the axis which expose possible vibration affecting the positioning of the extruder

- different models, e.g. stress-01-ybed-xz-head.stl or stress-printrbot-original.stl, stress-printrbot-jr.stl etc

- surface linearity

- simple and fast printing model which reveals surface linearity: several low volume (fast printing) large surface items with different steppings (e.g. different slice height for a Y-bed XZ-head RepRap); optical measurement, e.g. take photo of surface with a light source near perpendicular (right angle) so ripples cast a shade, then use program to analyze the dynamic range and contrast of that photo: uneveness of the surface.

- resolution

- Grid test print object, array of otherwise uniform grids of decreasing wall thickness (2, 1, 0.75, 0.5, 0.4, 0.3, 0.25, 0.2, 0.15, 0.1, 0.05 and 0.01 mm)

- material

- Printable hole test array, array of holes, from 1 to 30 mm in diameter as printed, designed to test the ability of a 3D printer to handle voids accurately.

- other tests (combined)

- Accuracy Master - Printing Test Kit, small perimeters, bridging, taller extrusions / large inlays, holes & arcs, slopes, peaks & small perimeters and infills

Replicability

Whether a threaded rod vs aluminium extrusion frame is closer or farther from RepRap I can't tell yet - it depends which part likely will be easier to be printed in the future.

Q: As been there any tests made with printed struts/rods/bars instead of steel rods, aluminium bars or laser cut plates?

A: Yes, listing projects:

Replicability Factor

I propose a RepRap Factor, printed parts (pieces & volume) in regards non-printed parts (pieces & volume), for example (made up numbers):

- rrf = (1 / (p + np) * p)

- rrfpieces = 1 / (30 + 220) * 30 = 0.12 = 12%

- rrfvolume = 1 / (20cm3 + 50cm3) * 20cm3 = 0.286 = 28.6%

A pure or 100% RepRap or rrf has 100% printed parts, 0% non-printed parts.

To compare weight seems not so informative, e.g. stepper motors are heavy, yet, a well designed strut with little infills but good inner structure weights little, so the information of the replicability to compare weight isn't so good.

Pellets

The MakiBox aims to be an All-In-One, you fill in pellets (1-2mm large pieces of material), it creates filament internally for the extruder - ideal for recycling. It's still in development stage (2012/07), see also Recyclebot.

Homemade Bio Plastics

To keep the idea of open hardware also apply to the source of material to be printed, I was looking for ways to make bio(-degradable) plastic from ingredients, e.g. from cornstarch, water, glycerin and vinegar - and experiment thereby also with softer and bendable material to make elastic printed forms (e.g. soft parts of a wheel or ribbon) or foamy parts (extreme lightweight). Some critical thoughts (The Guardian, 2008) and here on bio plastic in general.

Q: Any experiments with direct ingredients to mix to make pellets or filaments or feed the extruder direct?

Making RepRap a CNC Machine / Hybrid

Switch the extruder with a small milling head; consideration: strength of stepper motors and material to cut.

Q: Any projects?

A:

- See Forums.RepRap.org: CNC Routers, Mills, and Hybrid RepRapping for on-going discussion

- SumPod, 3D Printer & CNC

- PopFab, machine that does 3D printing, milling, vinyl cutting, and drawing, all while fitting inside a small suitcase

Price of Printing

It was pointed out at User:Traumflug user page, that printing itself costs:

- material

- electricity

printing a set for a RepRap takes up to 10 hours.

Q: Are there any more substantiated numbers how many resources are used (usage of material, electricty) and therefore cost of printing of a RepRap?

Dynamically Adjustable Size of Nozzle Hole

The precision of the printing is highly dependable on the size of the nozzle hole e.g. 0.3mm or 0.1mm - usually the precision of positioning is much higher 0.02mm or so and therefore neglectable in this consideration. It would be interesting to consider a nozzle hole which can be dynamically adjusted in size: for outline lines (becoming surface) go 0.1mm, and for the interior 0.3mm or even bigger for structural strength.

Q: Any projects which has considered or implemented that?

Further Considerations

On 3D Printing in general: 3D Printing - The Next Technical Revolution (2012/07)

Contact

- G+: [1]

- Email: spiritdude AT gmail DOT com