Y Bed Simplified

Release status: unknown

| Description | Y Bed Simplified

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | Y

|

| CAD Models | |

| External Link |

Contents

Overview

The original Mendel Y bed upon which printed objects are deposited requires complex shapes to be cut out and uses rather a lot of parts. This design is much simplified, and has just 8 printed components, half of which are clamps. It is intended for use with a simplified Y Motor Bracket http://www.thingiverse.com/thing:2011 and a 608 bearing in place of the standard Y Ider Bracket. The bed itself can be cut from MDF 8mm or more thick, veneered or not. You could also cut it from acrylic, quality plywood etc.

Unlike Ed's original design, this one does not use any bearings. Saddles on the ends of four printed feet provide a sufficiently low friction interface, particularly when printed in HDPE or PLA. These are held onto the platform itself with woodscrews, further simplifying construction. The use of steel rails is recommended, though aluminum ones will probably hold out for a while.

The clamps will attach the platform to either ball-chain (that was an interesting experiment) or the usual drive belt.

This design is also applicable to Prusa-type 3D printers.

Assembly

Read through, and make sure you have all the bits - or can bodge round it.

Cutting The Bed

Pre-cut beds are available from Mindkits.co.nz or you can cut your own deposition platform from a flat, undistorted sheet of your chosen material. For this example I will use 10mm veneered white MDF as usually used for making shelves. Being a lazy person, I will only trim it to 230mm in one direction, so leaving the nice decorative edges. The veneer will protect the MDF from any accidental splashes with lubricating oil. MDF will swell and distort if made wet with water or oil. Mark the centre line and decide which side you'll be screwing into.Print out the PDF template http://www.thingiverse.com/thing:2105, and stick it onto the platform, aligning it with the centre line carefully. Use a pointed punch or other whackable pointy tool to knock holes through the template and mark the platform. Remove the template (you can usually get 2 or 3 platforms out of one template).

Take a drill bit that will make pilot holes suitable for the woodscrews you will be using. For the one I use, that's 1.5mm diameter. Use a bit of tape to mark off half the thickness of the board on the drill bit so you don't drill in too deep. It does not matter much if you do, but it does matter if your screws stick through the other side later!

Preparing The Feet

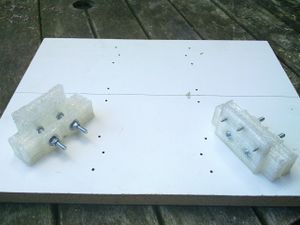

Take one of the feet http://www.thingiverse.com/thing:1708 and put an M4x50 machine screw in through one of the two M4 holes in the flat side. When it goes through the first thickness of plastic, screw a nut on and tighten. The head of the screw and the nut should fit in recesses. Do it up nice and tight, because you don't want it to move again.

Repeat with another M4 screw in the other hole.

Now repeat with the remaining 3 feet.

Fitting Feet And Clamps

Select woodscrews that will go through the three countersunk holes on each foot, but not all the way through the platform. There should be only one way each foot can be fitted to the platform. Do not strip the holes. If the M4 screw heads do not allow the foot to fit flush with the bottom of the platform, warm up the foot and sink the M4 screw in a little deeper, then try again.Now try fitting the bed on the Y guide rails. Shift the rails so that they are parallel and fit the grooves in the feet. Turn the bed around - things should be symmetrical.

Usage

Cover the bed with 3M Scotch-Blue, medium- or high-tack painter's tape. Level the bed by tightening the locknuts to raise the feet that are too long. Check the level on all 4 corners of the platform by manually moving the head around with the power off. If all is well, start printing on it.