Screwball-Bot

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

These are good resources for creating wiki pages. Very Messy Example and Columbus --Sebastien Bailard 07:23, 10 September 2010 (UTC)

Release status: unknown

| Description | documenting a generic tool/artpiece

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

- 1 Files (Coming Soon!!!)

- 2 Description

- 3 Introduction

- 4 Project goals

- 5 Bill of Materials/Parts List

- 6 Mechanical Assembly

- 7 Electronics

- 8 Initial tool-chain software and firmware

- 9 Problems encountered with Screwball-Bot

- 10 Time taken

- 11 Costs

- 12 Performance, quality and calibration

- 13 What I would do different next time (yes, there will be another one)

- 14 More Examples

Files (Coming Soon!!!)

| FILE ID# | TYPE | DESCRIPTION | AVAILABLE FORMATS | CREATED/RESERVED BY |

|---|---|---|---|---|

| Your-File-Name | SOLID MODEL ASSEMBLY | These are CAD files for the Solid Model Assembly | .xml.zip, .stl.zip | --Example User 12:00, Today's Date 20xx (UTC) |

| Your-File-Name | CAD FILES FOR PARTS | These are CAD files for each part. | .xml.zip, .stl.zip | --Example User 12:00, Today's Date 20xx (UTC) |

| Your-File-Name | EVEN MORE FILES | These are are even more files. | .xml.zip, .stl.zip | --Example User 12:00, Today's Date 20xx (UTC)|- |

| Your-File-Name | SOLID MODEL ASSEMBLY | This is the final finished machine | N/A | --Example User 12:00, Tomorrow's Date, 20xx (UTC) |

Please edit this and click the links to put in your own files! --Sebastien Bailard 08:34, 10 September 2010 (UTC)

Description

My chunky T-Slot Bot with Ballscrews called Screwball-Bot.

It's designed to use as many off the shelf components as possible and any parts that need to be made are possible with simple tools and are mainly non-critical to the end quality or ability of the machine.

It's not as expensive as it may look to do this so don't discount it out of your budget until you have read more below -

The 'working' Screwball-Bot - May 2011 (It will never be defined as 'completed')

I need to work out how to add images to this page, hopefully this will show the columbus image below?

Introduction

After my first Repstrap (not documented sadly) in the summer of 2010 I decided to make a new machine based on T-Slot MCS Aluminium Extrusion – http://4.bp.blogspot.com/_yfTUA-zOIkk/TSSkkR3BdYI/AAAAAAAAAHA/aIeTHqk7BBI/s320/30_30_MCS.jpg

Project goals

The original design aims for Screwball-Bot were defined in Jan2011, being 20 goals -

- Faster print speed - (This is my main driving factor after having a slow Repstrap for 6 months)

- Change to Ballscrews on X and Y Axis (not sure about Z at the moment)

- Revised Electronics (Mega based - and RAMPS based)

- Integral Electronics Tray and wiring with reliable connectors.

- Change from a fixed to Moving Y bed and print platform.

- Remove the Gantry head arrangement for the Z axis - Need to think of a simple way to do this...

- Simplify the Z axis by using dual Nema 17 motors (I may regret that decision...).

- Increase build-area to 300mm x 450mm x 300mm (Y being easily changed from 100mm upwards)

- Have easy-fit/remove build platform at different sizes and thickness

- Vertical mount Extruders

- Dual Extruder ends with remote mounts for Bowden mounted extruders

- Switch to Herringbone Extruder Gears

- Filament coil store and supply feed for 2 reels built into the machine

- Heated bed

- Resistor block Hot-ends

- Multiple Thermistors / readings

- Use as many off-the-shelf components as possible

- Use the off-the-shelf parts to maintain quality and accuracy in the design

- Do the minimum amount of machining as possible

- Where I need to do machining then it needs to be non-critical or easily adjusted to retain quality

I also want the ability to add Paste extruders and all sorts of other things, so the mounting and exchange should be as easy as possible with minimum (no) re-calibration required.

And 1.75mm Filament was getting more available and clearly making a difference, so using that was another project goal.

Bill of Materials/Parts List

Parts used – ready made / off the shelf

- MCS Aluminium Extrusion -

- part

- part

Parts home-made - for the machine build

- part

- part

- part

Parts used – ready made / off the shelf Parts used – ready made / off the shelf

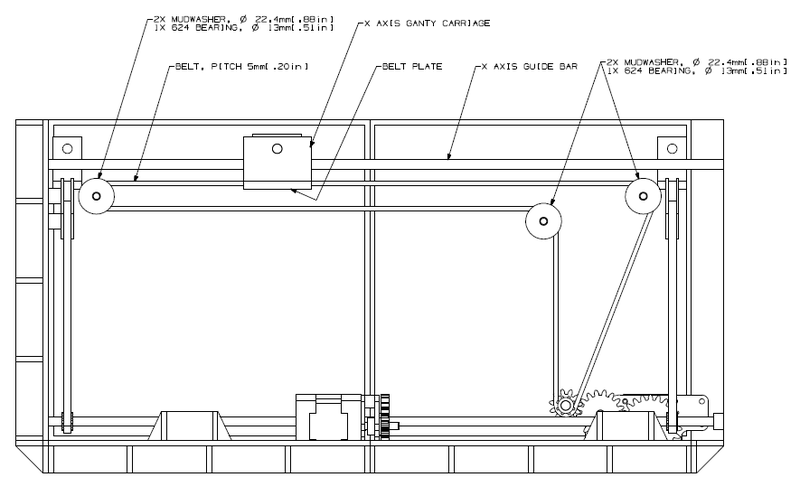

Mechanical Assembly

Electronics

(Remember to add links to RAMPS, steppers and the MEGA) Design Manufacture Assembly Testing