Rosalind

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: Working

| Description | A fully parametric GPL printer designed in OpenSCAD

|

| License | GPL v3

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Rosalind

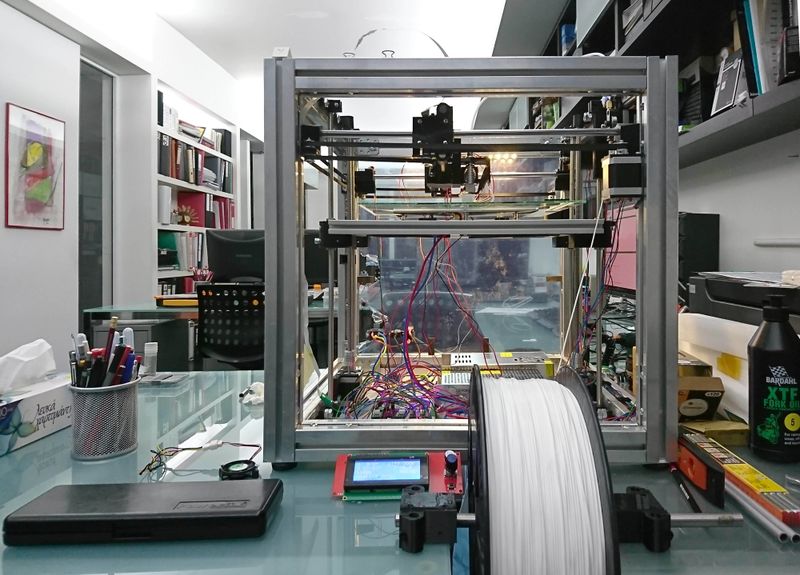

A CoreXY parametric 3D printer fully designed in OpenSCAD. You can clone the repository, change the parameters in general-values-n2.scad and print your very own rosalind. Step by step printing and assembly instructions coming soon.

This wiki can be easily converted to MediaWiki for publication in the Reprap wiki. See convert to MediaWiki for more info.

The bill of materials lists all the parts you will need to purchase to build your own Rosalind.

Basic Printing Instructions

- Clone the git repository.

- Open general-values-n2.scad and edit as you wish. The comments should help you choose the right values.

- Save as general-values.scad overwriting the existing file.

- Open rosalind.scad and view your build. Does it look right? Not all possible values have been tested so you have to take a good look here and make sure everything looks alright. If unsure just go with the defaults.

- Open the part files one by one and uncomment the print() statement. This is not very straightforward yet but it will be fixed in the next release.

- Press F6 and then export to .stl

- Print the stl files

Basic Assembly Instructions

Coming soon. For the time being use rosalind.scad as a guide if you’d like to print your own rosalind.

WIP: Build Your Own Rosalind

So, you want to build your very own Rosalind. Great. Let’s get started.

First clone the repository or Download the zip with all the files.

You will need OpenSCAD in order to customize and then print the parts needed for your build. Go download a copy for your system.

Open variants/general-values-n2.scad with your favorite editor. You can customize most of these values but apart from the defaults and the ones in general-values-n1.scad no other values have been tested yet. In the future as more configurations get tested we will include more sample files, or even a separate repository of configurations.

For this tutorial we will assume you are building an unmodified Rosalind-N2.

Let’s begin.

The frame

In order to build the frame you will need 4 things. Aluminium extrusion profiles (or any other kind of beams you can easily screw on), angle fasteners, M5 bolts and M5 t-slot nuts.

The t-slot nut pictured are generally more convenient as they can easily be inserted and removed in the t-slot, and they secure by rotation. However the variant with ball and spring has the advantage of staying put after unscrewing the bolt so it might be preferable for some parts. If you can, procure enough of both.

If you open rosalind.scad in OpenSCAD and look at the console (If you cannot see the console make sure View > Hide Console is unchecked) you will see some information about the printer being output, including the two lines:

ECHO: "Vertical T-Slot profiles (4 pieces): (mm)", 400 ECHO: "Horizontal T-Slot profiles (8 pieces): (mm)", 360

This informs us of the lengths of aluminium profile required to build our rosalind configuration. We will also need some angles to fasten them together and we can find off-the-shelf ones but since this is a RepRap and one of the goals is to be as much printable as possible we will print the angles ourselves.

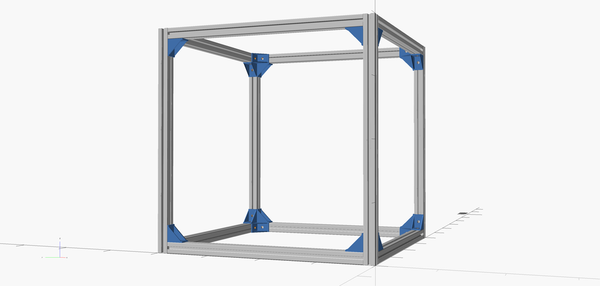

Open angle-fasteners.scad in OpenSCAD, press F6 to render and then export to STL. Load the STL file into your slicer, your printer, or order a print from a commercial print service. You will need 26 angles and the file has 30 so you will have a few extra if anything goes wrong.

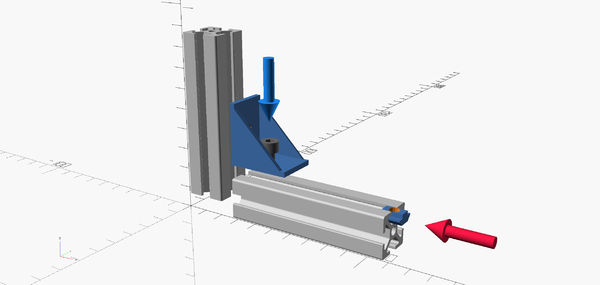

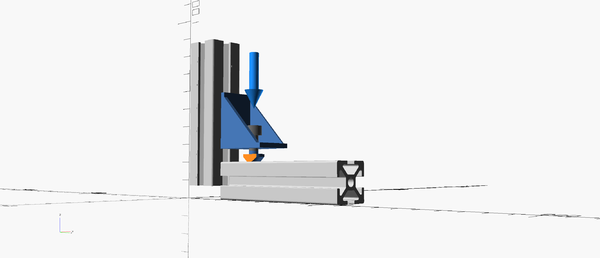

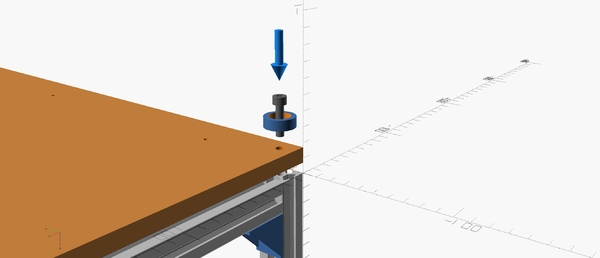

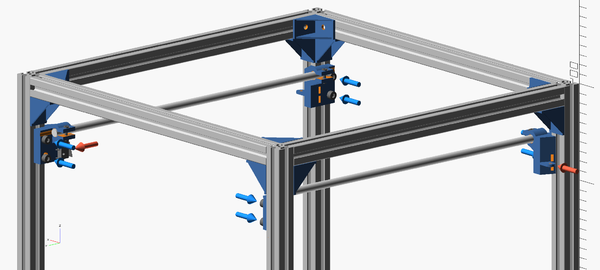

As long as you have printed the angles you will have to assemble a cube like this. Gather your aluminium profiles and set the 4 longest ones aside. You will use them for the Z axis (the upright frame elements, or “columns”) of your Rosalind. Slide the t-slot nut as shown.

If you have the self locking slot nuts pictured in the photo above along the bolts and aluminium profile then the easiest way to assemble is to screw the nut to the bolt before inserting into the frame, like below.

Continue with the rest of the corners until you have a cube.

The base (bottom)

You can use a sheet of acrylic for the base of the printer but I have found that a piece of moderately thick plywood (~10mm) is a safer choice. It’s easier to cut it yourself, it doesn’t crack and you can later screw on additional equipment easily.

Open base.stl in OpenSCAD, render it (press F6) and export it in .svg or .dxf. You can now print the drawing in a (2D) printer or a plotter and use it as a guide to cut your piece of plywood and drill holes in the appropriate positions.

Once you have the plywood ready, make sure you sand the edges so that they will be smooth to the touch as the base will be accessible from the outside. Clean it well and make sure that no wood splinters remain.

The next step is to tap threads into the central hole of the vertical t-slot profiles. This can be done using a hand-tap or a power-drill.

You can watch this video to see how you can do that. If you do not have a tap or don’t want to bother, you can avoid this step by using sheet metal screws such as this which will thread the aluminium upon screwing on.

The y-axis

Now it is time to start fastening the first functional parts on the frame we just completed. Open y-axis-clamps.scad, and make sure print_all_y_axis_clamps(); is not commented out, and that everything else under /* Print or Preview*/ is. If you are printing the default Rosalind you need not pay attention to anything else.

Depending on the values you have chosen, the parts might need support structures to print successfully. You can do one of the following: (a) enable supports on your slicer, (b) changesupporttotrueor (c) changetwo_partstotrue. Option (b) prints the part with an extra leg which you will be required to cut by hand and option (c) divides the clamp into two parts which you will need to screw together using bolts.

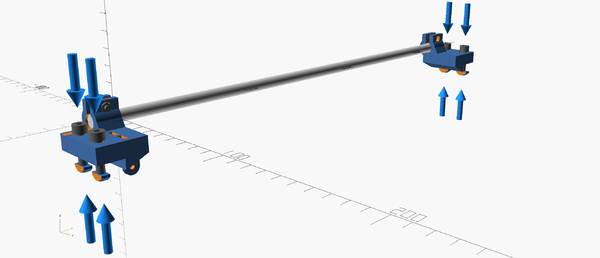

As the mounting screws of the y-axis clamps don’t allow the smooth rod to slide in after being mounted on the frame we will need to assemble the two sides and then mount them on the printer. This is arguably a little easier too.

Once you have printed the parts, get yourself 4 M5x12 or M5x16 screws, 4 t-slot nuts and 2 M3x12 plus nuts for each side.

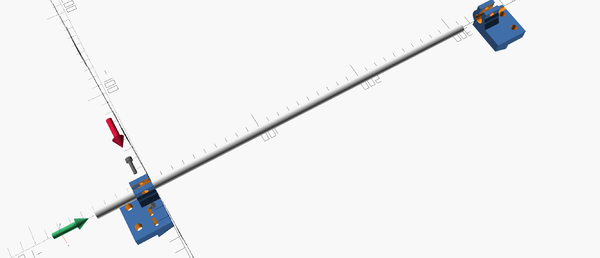

Slide the smooth rod into the y-axis clamps like this. Make sure that only one of the clamps has the two vertical belt slots.

After you install and clamp it at both sides you should add the frame bolts to the two holes in each clamp. Just screw the t-slot nuts on the backside for one or two turns so it looks like this:

After you have completed the assembly you will have to attach it to the frame like this:

Tighten the bolts enough so that it stays in place. Don’t bother too much about the exact Z position. We can adjust later.

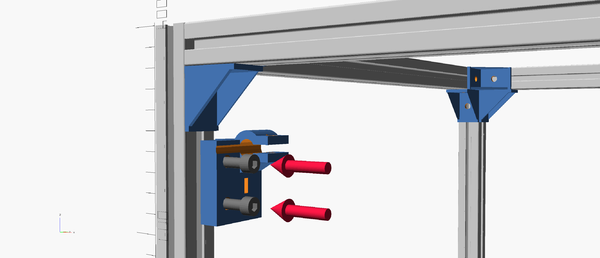

There are three kinds of y-axis clamps. Make sure you install them at their correct positions. Take note of the shelf where the timing belt idlers will later be mounted and the endstop position (Red arrows). Don’t mount the ensdtop yet, it’s just shown for reference.

In the default rosalind-n2 v1.1 configuration the clamp that will hold the endstop does not have a visible difference. This is not always the case depending on the values you selected in general-values.

The z-axis

As before open z-axis-clamp.scad, and make sure print_all_z_axis_clamps(); is not commented out, and that everything else under /* Print or Preview*/ is.

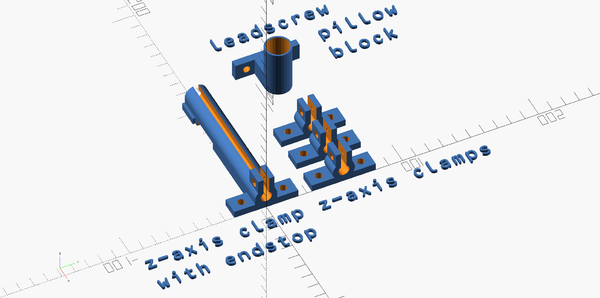

You will get these parts.

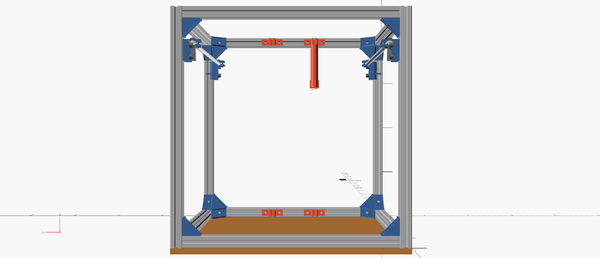

Set the pillow block aside for the moment and take the four z-axis clamps. The longer one mounts to the top horizontal frame beam to the back of the printer along with a smaller one. The other two mount on the bottom directly below. The x-position in which they mount is roughly 1/3 of the available space, such as so:

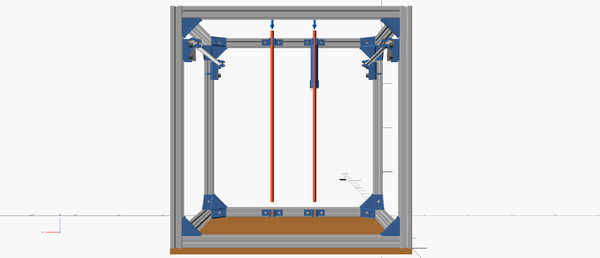

Now it’s time to slide the z-axis smooth rods from top to bottom into the z-axis clamps. You might need to pry the z-axis clamps open with a flat head screwdriver (especially the longer one) in order to be able to pass the rod through easily.