Witbox Diamond

Witbox Diamond

Release status: working

| Description | bq Witbox Diamond

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | RepRap Color 3D printing Diamond Hotend

|

| CAD Models | |

| External Link |

The intention of this page is to serve as a build guide for those who want to modify a bq Witbox for the triple extruder solution Diamond Hotend.

A little warning: this procedure will probably void warranty on your printer so before proceeding be sure you know what you are doing.

Contents

Part list

Most of the parts listed here are the same as mentioned on the original Diamond Hotend page.

Witbox Diamond main parts

- 1 x Diamond Nozzle 1.7 mm version

- 1 x Witbox Diamond Cooling Shield (Witbox Diamond cooler shield ver3.stl)

- 1 x Witbox Diamond X-carriage (Witbox Diamond X-carriage ver3C.stl)

- 1 x Witbox Diamond Z-endstop mount (Z-endstop holder.stl)

- 3 x Diamond thermal insulation sheet

- 1 x Thermal compound

- 1 x Heater cartridge

- 1 x Thermistor NTC 100k wired

- 3 x E3D LiteV6 with bowden fittings

- 1 x Axial fan (12 volt / 50 mm / at least 18 CFM)

- 1 x Radial blower fan (12 volt / 5015S) (you can use the one from the original bq HeatCore extruder)

- 4 x Cable tie

- 6 x M3 nut

- 1 x M4 nut

- 2 x M3x8 CSK

- 3 x M3x10 CSK

- 4 x M3x20 CSK

- 1 x M4x30 CSK

- 2 x Pin header Male 2P 2.54 mm spacing (Molex KK or Dupont type)

- 1 x Heat shrink

Bowden extruders

- 3 x Bowden tube OD:4/ID:2/L:650 mm

- 3 x MK9 extruder

- 3 x MK9 extruder motor cable

- 3 x MK9 extruder mount (MK9_bowden_laser_right.stl)

- 3 x Bowden tube push fitting

- 6 x M3x20 bolt

- 1 x Lasercut extruder mount (T_mount.dxf)

- 1 x Braided sleeve 20 cm

- 1 x Cable tie mounting pad

- 2 x Cable tie

- 1 x Filament roll holder (Spool_holder_32mm.stl)

- 1 x Filament roll holder (Spoleholder_T-Mount.stl)

Endstop

- 1 x Z-endstop adapter (Z-endstop_holder.stl)

- 2 x M3 nut

- 2 x M3x6 bolt

Electronics

- 1 x Stepper Expander X1

- 2 x Stepsticks

- 4 x Adhesive PCB spacer (RS: 220-787)

- 10 x Cable tie (estimated pcs.)

- 2 x Wire from PSU to Easy Expander

- 1 x 2x5P IDC cable from Ramps AUX-2 to Easy Expander

Assembling

Electronics

- To access the electronics compartment first remove the right side cover by unscrewing the four outer hex bolts on the right side of the Witbox.

- Then unscrew the smaller hex bolt inside the Witbox.

- Unscrew the two smallest hex bolts on the frame.

- Carefully remove the lid of the electronics compartment.

- Mount the Stepper Expander X1 (or pb ExtrudrBoard) between the RAMPS and the PSU using the adhesive PCB spacers.

- Connect The Stepper Expander (or pb ExtrudrBoard) to the RAMPS AUX-2 using the 2x5P IDC cable.

- Add power wiring from PSU to the power input terminals on the Stepper Expander (or pb ExtrudrBoard).

- This step only applies if using the Stepper Expander X1: While observing the direction insert one stepstick on the vacant position on the RAMPS board and the other stepstick into the Stepper Expander. (The trimpot on a standard A4988 driver should be closest to the power terminals on the Stepper Expander).

- Mark the extruder motor cables respectively "A", "B" and "C" in both ends.

- Feed the cables through the back rear right corner panel.

- Tie all wirings in the electronics compartment so that no wire are blocking the airflow from the cooling fans down onto the stepper drivers.

Hardware

- Dismount the original bq Heatcore extruder

- Dismount the x-carriage (release belt tension by loosening the hex bolts holding the pulley on the left of the x-axis)

- Optional: if you have decided not to switch back to using the original bq HeatCore extruder you may remove the original extruder motor cable. Carefully release the individual wires from the black female 4p Dupont extruder plug connected to the RAMPS board (use the tip of an exacto knife) and cut the cable ties along the cable and you will be able to pull out the wires from the x-carriage end, one at a time. Newer versions of Witbox uses wire chains which can be opened which makes this process much easier.

- Cut the axial fan wires to about 10 cm length, strip the ends and solder a 2 pin male header onto the ends, remember to slide a piece of heatshrink over each wire before soldering and carefully shrink the tubing around the solder joint using the heat from a lighter flame.

- Assemble the Diamond Witbox Cooling shield and mount the M3 and M4 nuts into the respective slots (for more detailed description on this procedure please follow the guide on Diamond Hotend).

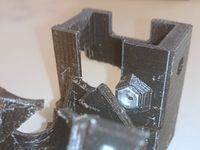

- Your Diamond Witbox Cooling Shield should now look like this.

- Print out the new x-carriage part and mount the two M3 nuts into the respective slots. If they are too loose you may glue them into place and if they are too tight to fit you may heat them into place using a soldering iron like described on the Diamond Hotend page step two.

- Attach the new x-carriage to the x-axis, then wrap the belt around the designated belt holder and then retighten the bolts at the belt pulley.

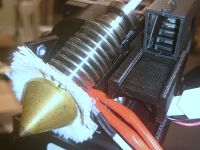

- Mount the top part onto the x-carriage using three M3x10 countersunk bolts. Please observe that the thermal insulations does not get stuck anywhere between the two printed parts. Then secure the protruding cables and plugs onto the wire chain.

- Unscrew the Z-endstop switch at the inner rear if the Witbox and reinstall it onto the adapter using two M3 nuts and two M3x8 countersunk bolts.

- Remove and cut holes in the back cover according to the instructions on the "Diamond upgrade parts for Witbox" page (see link below).

- Remount the back cover while feeding the motor cables through the corresponding hole.

- Add the braided sleeve onto the motor cables.

- Mount the lasercut T-shaped piece.

- Mount the adhesive tie pad.

- Tie the motor cables onto the tie pad using a cable tie.

- Assemble the bowden extruders (follow the steps on Diamond Hotend).

- Mount the extruders and connect the motor cables.

- See section "Assembly" step "Attaching the bowden tubes" as well as "Bowden tube hints" section on the Diamond Hotend page.

Firmware

- bq Witbox firmware adapted for Diamond Hotend on GitHub (link is being contructed)

Printed and lasercut parts

- Diamond upgrade parts for Witbox by RepRap.me