User:Vincenticart

Vincent Icart RepRap Wiki

| RepRap User: Vincent Icart | |

|---|---|

| University | Penn State |

| Class of | Summer Internship 2014 |

| Major | General Engineering, École Centrale de Marseille [1] |

Contents

About

The purpose of my internship is to do research on open-source 3D printing. I was involved in a Fablab in my university back in France where we used an Ultimaker and CubeX Duo. I didn't have any hands on experience on Repraps before arriving here, so the first weeks were dedicated to understand and get confortable with the use of these machines. Then, I could start trying to fix the different machines in the lab along by working on anxiliary projects. Below are the main progresses on the printers.

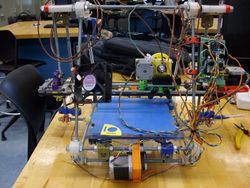

Rainbow

Rainbow was close from working when I got here. Here is a list of the most important works done on the printer:

- Equipped with the fan.

- Reflashing the arduino as connection issues were experienced.

- Calibration.

- Squarring of the frame.

- Removing and putting back on the extruder as it was clogged, and rewiring of the hot tip as a short kept triggering a "Max temperature" reached while printing.

The printer is now printing well, although the calibration part shows that best results could be acquired if the axis were squarred more accurately. Besides, on some specific areas, the infill doesn't reach the perimeters.

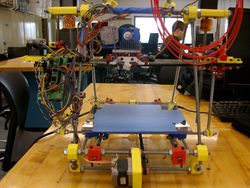

Mc Donald

This printer required some work to get it back working.

- There was a lot of slack for the carriage which could rotate a little around the Z axis. Actually, a all new carriage was printed. Also, the long arm was printed with a new version of the file. The new version is the same as the old one, except that the four or five last layers that made the middle of the part higher where cut. This allows a tighter assembly to the main part of the carriage around the rod. This way the slack issue was fixed. As the carriage was removed, this was also the occasion to add a heat exchanger on the carriage.

- The bed was replaced by a polycarbonate one in order to prevent warpage issues. This allows better print results as first layers stick better to this kind of beds.

- X and Z axes motor drivers were replaced.

- Squarring of the frame and calibration of X axis (multiplication factor: 1.039).