Thermoplast Extruder Hints

Bed Materials

Some bed materials work better than others. ABS does not seem to stick to the MDF bed at all. So far I've tried the following with ABS:

Electrical tape - sticks, but not well enough to stop warping.

Glass - doesn't stick at all.

CD-Roms - sticks well, gives a nice surface finish, but tends to warp. Build area is obviously very limited (and circular!).

Acrylic Sheet - works! ABS sticks to it quite nicely; I had some warping, but I only used 1.5 mm thick Acrylite FF P99 Acrylic Sheet from Cyro Industries. I've got some thicker stuff to test again as soon as I get my extruder running without the flexible drive.

Wade 2008.10.01

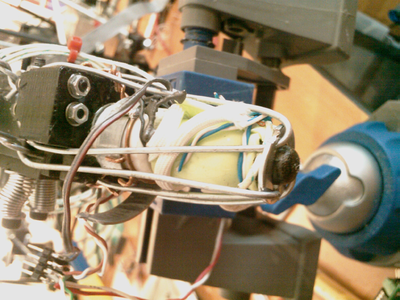

Insulation of the heater barrel

There's a good alternative to glass fiber wool, a material I wanted to avoid. It will give you an itchy skin because you have a lot of small cuts from the glass. What I did differently, I cut a rectangular piece out of a 'silicone baking mat'. You can find these in a cooking store or various other places. It can handle high temperatures (above 300 without any problems, I guess) and it's very rubbery. It can hold everything together very easily and it can be removed as well (as opposed to fire cement). It doesn't have much specific heat, so the extruder will heat up (or cool down) quickly, because only the copper needs to get very hot.