TechZone Tip Assembly

The instructions on this page are for assembling the tip and extruder kit(s) from [TechZoneCommunications].

The information may be useful for general assembly of tips and other designes, but no attempt is made to address them specifically in this document.

Background

Here at TechZone (short for TechZoneCommunications) we have learned the hard way, that the tip is probably the hardest and most finicky part in the RepRap. Unfortunately that set us up to cause a lot of problems for many of you (our customers and design users).

When we first released the LaserCut Mendel (LCMendel) we thought it would be a piece of cake to make and deliver hot ends, after all, everyone with a RepRap has a hot end and we presumed that they worked just fine. In the weeks (which became months) that followed we found out that we were Fools (notice I capitalized that word). We probably spent far too long re-inventing the wheel, and should have bitten the bullet and purchased everyone their favorite tip and called it good. That certainly would have saved us some money!

Even with the current version of tips that we have shipped, I am not completely content with the design, I am certain that there are some improvements to be made. However, what we currently provide (Aug 27, 2010) is a good design, and I am confident it is no more finicky or flawed than the many other designs out there. I did break down and order several in from other vendors and set them up to use them before I finally released our tip.

Contents

Hot End Assembly

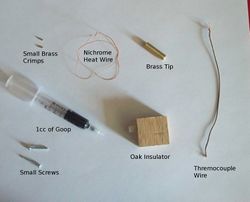

Here (on the right) is a picture of the parts we include in the Hot End kit:

Included in the Kit

- (1) Brass tip; it is machined from a solid bar of brass and threaded to a standard 7mm thread, bored with ~3mm bore until it is about 1mm from the end, the end has a 1/2mm hole in it and is ground with a taper.

- (1) Oak Insulator, with Teflon insert; We played with several insulators, and didn't like any of them we even had trouble with the standard Teflon and/or peek insulators, then we found on a chart that Oak is 1/10th as conductive as the Teflon or peek! So, we make the insulator out of oak. We recommend some care in your firmware and tip construction, Wood is flammable....

- (1) Nichrome heater wire; This wire is insulated with fiberglass, but that fiberglass is just wrapped on the wire, so we overcoat that with high temperature silicone so that it doesn't unravel as you use it.

- (1) Type K thermocouple wire; This is insulated in a fiberglass braid, it has two wires in there, one wrapped in Yellow the other wrapped in red.

- (1) 1cc of High Temp Goop; we use two different kinds of "Goop" one is a high temperature silicone - which is copper colored - purchased from an auto parts store, the other is a silicone cement - which is black - purchased from a hardware store (both come in large qty packages, so we repackage it into a small syringe).

- (2) small brass or copper crimp connectors (these are shipped to you in a small envelope)

- (2) Small screws to attach the Oak block to the extruder body

Hot End Assembly Instructions

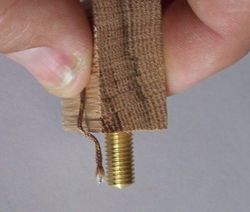

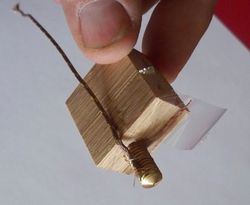

First, thread the brass tip into the oak insulator, it should be firm against the Teflon insert, but do not over-tighten, as the Teflon will distort under too much pressure and your filament will then have trouble fitting through the Teflon into the tip. A picture of the insulator, with the tip inserted is shown on the right:

Thermocouple A-D converter with OneWire

Connection to the Extruder Body

History of our design

Some people have asked for pictures of our development process, and regretablly, I don't have pictures of all the designs we made and tested, but here are a few of the more noteable pieces. If you are one of our customers who recieved something different than what is in the photos here, please take a picture and post it to this section, I will add descriptions of what we were attempting to do.

Many Thanks to all of you who have helped (both directly and indirectly).