Scratch n' Etch PCBs

The Scratch n' Etch method for producing PCBs uses an etch resist that is scratched away with a CNC and a carbide scriber. This page documents a successful version of this method done on a McWire-style CNC by Matt Gilbert. (While some have declared the McWire a "death march", it works fine in this case, albeit a little slow. More importantly, the method shown here should be easily incorporated into a different RepRap/RepStrap design.)

Overview

The scratch n' Etch method has been described in principle on the Homebrew PCBs Yahoo group. This page documents the Scratch n' Etch process as explained on that discussion board, with one important addition: The scriber is pressure sensitive.

The etch resist used is Dykem Layout Blue (aka "machinist's paint", "machinist's blue", or "layout paint"). This paint is used by machinists because it's designed to be easily scratched off with a carbide scriber, leaving behind a fine, precise line.

The scriber exposes copper that can be removed using your favorite etch. (Cupric chloride is a good choice because it's reusable.)

Since the scratches themselves are the areas that will be removed, you must isolate the traces and areas you want to keep by scratching around them.

Since the scratches are very thin, to get adequate isolation you have to scratch a few "laps" around each trace, sort of like a lawnmower, moving a little further out each time, scratching away a thicker line. This requires your GCode to include these "laps".

The trick to making this method reliable is to make the scriber pressure-sensitive, rather than simply calibrating a fixed "scratch-height". It's not likely that the bed of your CNC and the copper-clad board you are scratching are perfectly level. Rather than attempt to level it, adding a pressure sensor allows the machine to adjust it's height as it scratches. If it starts scratching to hard, it lifts up a bit. If it's scratching too lightly, it will lower the scriber a bit.

Step-by-step

| Photo | Description |

|---|---|

| Step 1: Clean the board. Start with a copper-clad board. Clean thoroughly with steel wool and acetone. Allow a few minutes for the acetone to evaporate. | |

| Step 2: Paint the board. Paint a single, thick, even coat of Dykem Layout Blue. Using the in-cap brush seems to be the easiest way. | |

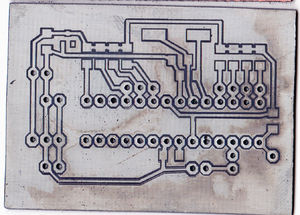

| Step 3: Scratch away the paint to expose the copper that you want to remove. This means removing the copper around a trace, isolating it. Scratch a few "laps" around the trace to make the gap wider than a single scratch, since a single scratch is likely to get bridged with solder. The GCode for this method needs to take this into account, as well as the pressure-sensitive modes. One method of producing this GCode from PCB designs will be explained in the Software section. | |

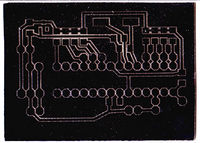

| Step 4: Etch the board with your favorite etch. (Cupric chloride is a good choice because it's reusable.) | |

| Step 5: Drill holes for through-hole components. This board was drilled with a Dremel attached to the CNC. Drill after etching to avoid etching away metal on the inner ring of each hole. | |

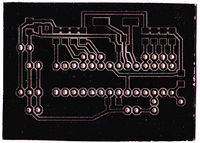

| Step 6: Clean of the paint. This board was drilled with a Dremel attached to the CNC. | |

| Step 7 (optional): Tin the board using Liquid Tin. Liquid Tin deposits a layer of tin over the copper, preventing the copper from corroding or oxidizing over time and making it a little easier to solder. If you skip this step, your board will probably work fine, though the copper may get a little ugly after a while, and may even stop working eventually. |

Software

Generating the GCode

The GCode used for the Scratch n' Etch method is different from the GCode used for isolation milling or other processes. The main differences are:

- The path must go around each trace several times, moving slightly further out each time.

- There must be a command to turn on a "pressure-sensing mode", during which the CNC will raise or lower the scriber to maintain a certain amount of pressure. (This also requires changes to the firmware of the CNC, which are explained in the CNC Firmware section.)

The particular method for generating GCode may be different depending on your needs. The particular syntax explained here was created ad hoc, and may conflict with other CGode conventions.

More to come

CNC Firmware

More to come