RepRapPro Mendel z axis assembly

Contents

This page is under construction

Introduction | Frame assembly | Y axis assembly | X axis assembly | Z axis assembly | Heated bed assembly | Extruder drive assembly | Hot end assembly | Power supply | Wiring | Commissioning | Printing | Multi‑colour/multi‑materials | Colour Printing - Slic3r | Colour Printing - RepRapPro Slicer | Maintenance | Troubleshooting | Improvements

| A notice about these instructions! |

|

Since 1st April 2013, the RepRapPro Mendel has been superseded by the RepRapPro Tricolour and Mono Mendel. |

Goal

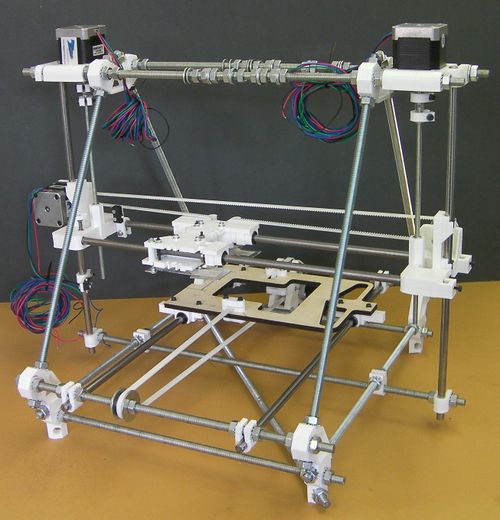

By the end of this stage, your RepRap should look like this:

Tools

You will need the following tools

- M3 Allen key

- M3 spanner/nut runner

- Small screwdriver

- M2.5 spanner

- M8 spanner

Step 1: Z axis screw drives

| |

| Item | Quantity |

| NEMA 17 motors | 2 |

| 60 mm springs | 2 |

| 215mm M5 studding | 2 |

| M5 nuts | 4 |

| 30mm x 5mm id poly tube | 2 |

| Printed U clamps | 4 |

| M3 x 20mm screws | 4 |

| M3 nuts | 4 |

| M3 x 10mm screws | 8 |

| M3 washers | 12 |

Start by using the short screws with washers to fit the Z motors to the frame:

Have the wires point towards the centre of the machine.

Next fit the M5 threaded rods, M5 nuts and springs to the X axis:

Screw a nut onto a rod and make sure that it fits down the hexagonal holes in the X-axis ends. It should be snug, but move up and down freely. If there are tight spots inside the hexagonal holes scrape them away with a screwdriver blade.

Now fit the nuts and rods. Put a nuts about half way along a bar, put a spring on, and push the spring down the top of a hexagonal hole.

Compress the spring and put another nut on the bottom of the thread. When the spring relaxes it should pull that nut into the hole in the bottom of the hexagonal hole to rest on the constriction about 10mm up inside. Adjust things so that the top nut is about flush with the top of its hole.

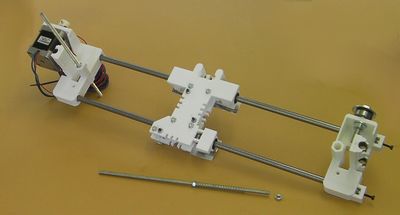

Next assemble the flexible couplings:

Put the U clips on the poly tube, then put the screws through. Don't tighten them. Screw the poly tube onto the ends of the M5 rods as shown. Then tighten the U clips that are on the threads but leave the others lose.

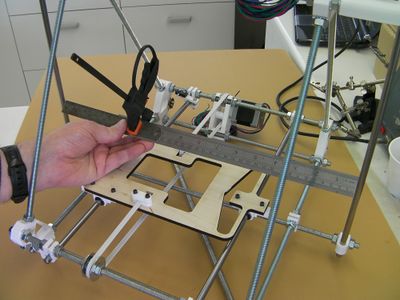

Now check that the Z rods are parallel:

A simple way to do this is with two rulers clamped together as shown. Check the gap bottom, middle and top. Make adjustments by slackening and tightening the M8 nuts that clamp the bottoms of the Z rods. Make the adjustments symmetrically - whatever you do on the left, also do on the right. You may find it helps to mark the nuts with a felt-tipped pen so you can see how far you turn them.

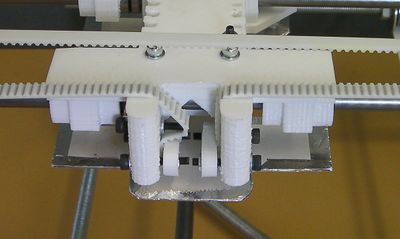

Step 2: Fit the X axis

Slacken the nuts on the Z motor mounts that retain the Z rods. Slacken the outer nuts on the U clips at the base of the Z rods. Make sure that the inner nuts do not move - then when you re-tighten things everything will go back to the same place.

Slide the Z rods upwards by about half their length. You may need to tighten the top nuts by hand to stop them falling again.

Move the Y frog to the middle of the machine.

Put the X axis on the Y frog. Take care not to damage the heat shield. Pack the X axis up with a scrap of wood or similar to get it level and stable.

Push the left-hand Z rod down through the IGUS bearing inserts by the X motor and on down through the U clip at the bottom. Again, take care not to move the inner nut.

Tighten the outer nut on the Z rod, and also tighten the nut at the top on the Z motor mount.

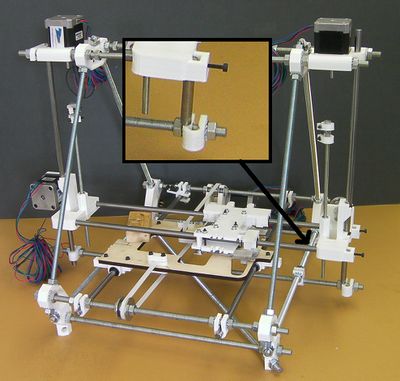

Push the right-hand Z rod down through the X carriage and stop just above its U clip.

The Z rod will be on the inside of the U clip. That is to say, the X axis is (deliberately) too short. (See the inset image.)

With an M3 Allen key, tighten the screws in their nylock nuts on the ends of the X rods. The bottom of the Z rod will move outwards. Adjust it so that it just lines up with the hole down the U clip, then push it on down through the U clip.

Tighten the nuts on the Z motor mount and the outer nut on the bottom U clip to hold the right-hand Z rod firmly.

Finally for this step, lift the whole X axis and push the motor shafts into the tops of the poly tubes that form the flexible drive linkages.

Have gaps of about 2mm between the tops of the M5 rods and the bottoms of the motor shafts. (You can see this because the poly tube is transparent.)

Tighten the U clamps on the motor shafts. Try to get the flats on the shafts aligned with the gaps in the clamps.

Turn the Z motors by hand to get the X axis level. To check this, move the Y frog and the X carriage out of the way, and use digital callipers to measure the gaps between the Y rods and the X rods. These gaps should be the same left and right.

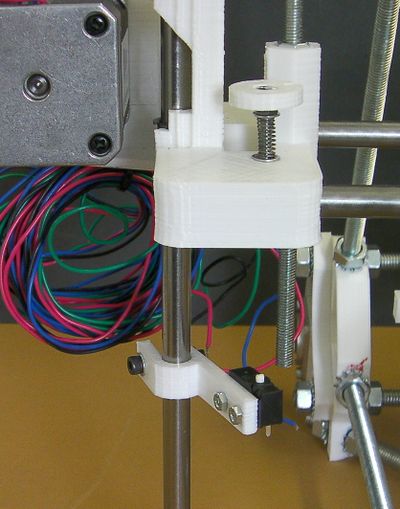

Step 3: The adjustable Z endstop

Note that the X and Y axis endstop holders are identical. The Z endstop holder has a longer leg; that is the one you want.

Start by using the 35mm hex-head screw together with nuts, washers and the spring to assemble the adjuster:

Then use an M3 nut underneath to fit the adjuster to the motor end of the X carriage:

Pull the nut into its hexagonal recess under the carriage. Make sure the two hexagons line up.

Assemble the switch together with the "h" shaped piece using the M2.5 screws, washers and nuts as shown and fit it to the smooth Z rod.

The remaining M3 parts close the h-clamp. Don't do it too tight - it needs to be firm and unmoving, that is all.

The switch button should line up with the end of the adjustment screw.

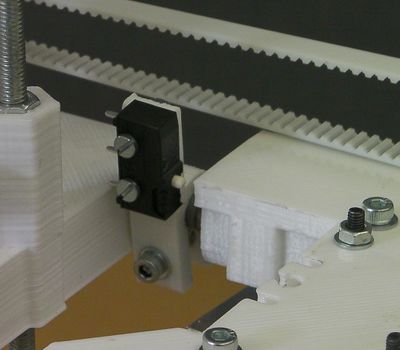

Step 4: The X belt and endstop

| |

| Item | Quantity |

| Printed XY-stop bracket | 1 |

| M2.5x15mm screws | 2 |

| M2.5 washers | 4 |

| M2.5 nuts | 2 |

| microswitch | 1 |

| M3 x 20mm screws | 1 |

| M3 nuts | 1 |

| M3 washers | 2 |

| toothed belt | 1000mm |