RepRapPro Mendel x axis assembly

Contents

This page is under construction

Introduction | Frame assembly | Y axis assembly | X axis assembly | Z axis assembly | Heated bed assembly | Extruder drive assembly | Hot end assembly | Power supply | Wiring | Commissioning | Printing | Multi‑colour/multi‑materials | Colour Printing - Slic3r | Colour Printing - RepRapPro Slicer | Maintenance | Troubleshooting | Improvements

| A notice about these instructions! |

|

Since 1st April 2013, the RepRapPro Mendel has been superseded by the RepRapPro Tricolour and Mono Mendel. |

Goal

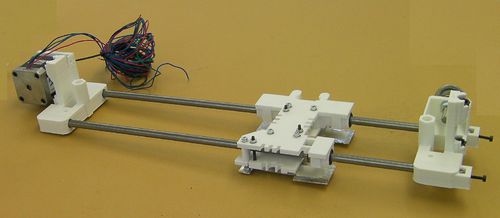

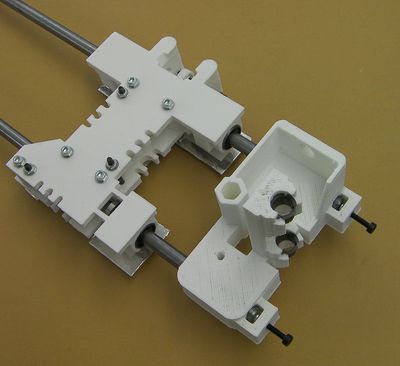

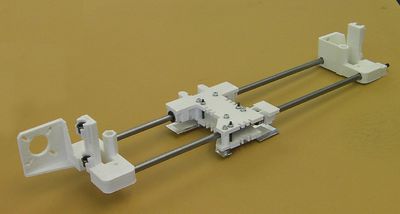

By the end of this stage, your X-axis should look like this:

Tools

You will need the following tools

- M3 Allen key

- M3 set screw Allen key

- M3 spanner/nut runner

- Long-nosed pliers

- Tweezers

- M8 spanner

Step 1: X carriage assembly

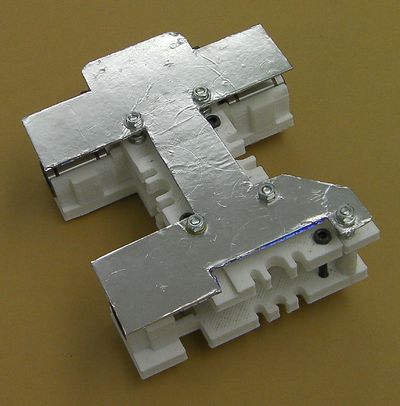

Start by gluing the aluminium foil to the cardboard heatshield. The aluminium needs to go on the underside of the cardboard when the cardboard is the way up shown in the picture above.

Virtually any glue will do, but aerosol spray glue is easiest. Spray the foil, then drop the cardboard onto it and press it down against a flat surface.

Trim the foil about 5mm out from the edge of the cardboard and fold it over and stick it around the edge on the back. You can make a neat job if you make rectangular cuts of the foil by convex corners, and 45 degree angled cuts in to concave ones.

Let the glue set.

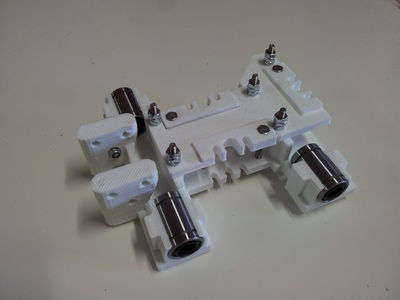

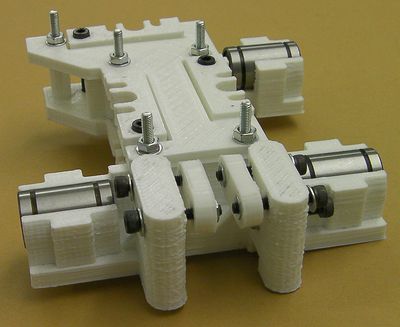

Next with the X carriage upside-down slide the LM8UU bearings into their holders sideways:

Don't try to fit the bearings by clipping them in from above - this will break the carriage.

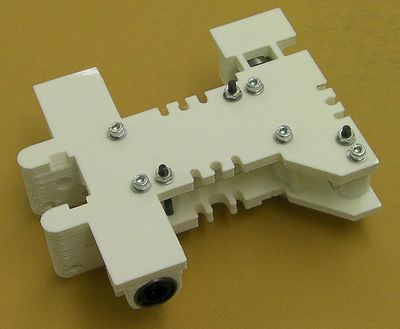

Use the 35mm screws with nuts and washers to secure the plate to the carriage. Have the ends of the screws projecting as shown.

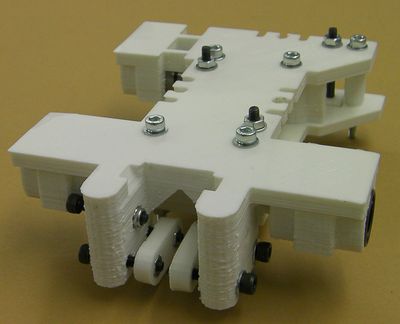

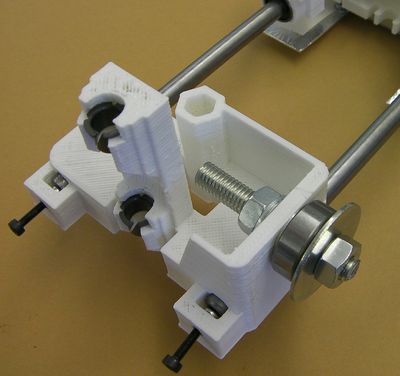

Fit the hex-headed screws in their recesses the other way up, and put nuts and washers on the ends:

Don't do these up tight. These screws allow you to adjust the relative heights of multiple extruders in the carriage.

Fit the belt clamps with screws nuts and washers as shown here:

Start by sinking the nuts into their recesses. You can do this most easily by pulling them through with a screw with a washer under its head. Make sure as you tighten the screw that the hexagon of the nut is aligned with its hexagonal hole.

The belt-gripping indentations on the clamps face the vertical pillars.

Fit the tensioning screw using the nylock nut as shown:

It doesn't matter on which pillar you fit it.

Finally, put extra nuts followed by washers on the five original projecting screws:

Fit the heat shield (the screws will easily and neatly puncture the aluminium foil). Secure it with washers and nuts.

Position the heat shield so that the nuts that retain it are just at the ends of their screws.

Step 2: Main X axis assembly

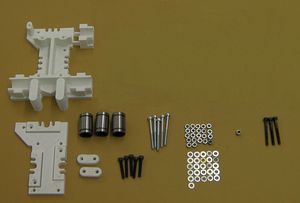

| |

| Item | Quantity |

| Printed X carriage lid | 1 |

[[File:|400px]]