RepRapPro Mendel wiring

Contents

- 1 This page is under construction

- 2 Goal

- 3 Important: general rules for wiring up

- 4 Tools

- 5 Parts

- 6 Wire routes

- 7 Attaching the control electronics

- 8 The power supply wire

- 9 The heated bed wires

- 10 The X motor wires

- 11 The Y motor wires

- 12 The Z motor wires

- 13 The X endstop wires

- 14 The Y endstop wires

- 15 The Z endstop wires

- 16 The extruder motor wires

- 17 The hot-end wires

- 18 Connections to the controller board

- 19 Testing

- 20 Next step

This page is under construction

Introduction | Frame assembly | Y axis assembly | X axis assembly | Z axis assembly | Heated bed assembly | Extruder drive assembly | Hot end assembly | Power supply | Wiring | Commissioning | Printing | Multi‑colour/multi‑materials | Colour Printing - Slic3r | Colour Printing - RepRapPro Slicer | Maintenance | Troubleshooting | Improvements

| A notice about these instructions! |

|

Since 1st April 2013, the RepRapPro Mendel has been superseded by the RepRapPro Tricolour and Mono Mendel. |

Goal

By the end of this stage your machine will be ready to commission.

All the wires from electric components in the machine run to the controller electronics.

What you are going to do is to route those wires round the frame from each component to the controller, leaving a generous extra length when the controller is reached and not at that time connecting the wire to the controller.

Then, when all the wires have been attached to the frame with cable ties, you will trim them and make the final connections to the controller.

You can either route wires and attach them with cable ties as you go. You will then have to clip off those cable ties when a new wire runs on the same route and add a new one holding both wires. This is slightly wasteful, but easy.

Alternatively, hold all the wires temporarily with sticky tape when you route them. Then go round the machine removing the tape and holding the wires with cable clips when all the wires are in place. This is more fiddly, but more parsimonious.

Important: general rules for wiring up

You will do serious damage to your RepRap electronics if the power is connected backwards. Other damaging mistakes are to short out high-current devices like motors and heaters, and to connect high-voltage devices like stepper drivers to signal inputs like temperature sensors.

So - in the sections below where it tells you to check things - please check them thoroughly. It is worth taking the time...

Also important for the steps below: when attaching wires to screw connectors, strip about 5mm of insulation off them, twist them between your fingers, and tin them with solder. The tinning is needed for good contact, and to ensure that fraying does not cause shorts.

When wires leave a device (like a motor) or arrive at a connection (like the screw connectors on the controller) leave a small slack length (about 20mm long) for strain relief - don't have the wires taut.

Finally, when making any changes to the wiring or any other electrical aspect of the machine, first disconnect both the power and the USB.

Tools

- Wire strippers

- Soldering iron

- Small screwdriver

- Vice

You may also need a reel of sticky tape.

Parts

| |

| Item | Quantity |

| Controller board | 1 |

| High-current wire | 0.5m |

| Printed U clips | 3 |

| M3 x 25mm screws | 3 |

| M3 nuts | 3 |

| M3 washers | 6 |

| 3mm i.d. plastic tube | 20mm |

| cable ties | about 60 |

Wire routes

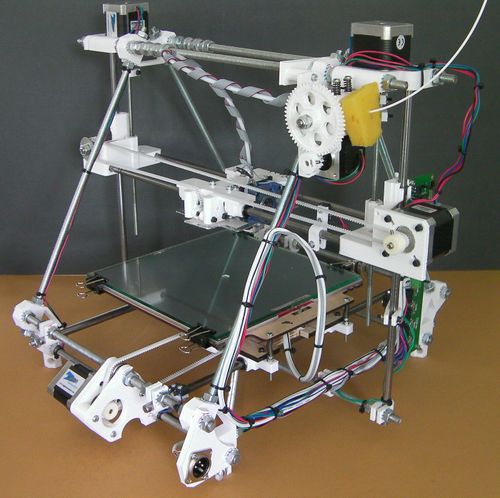

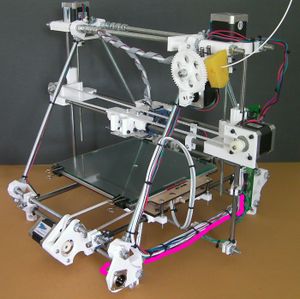

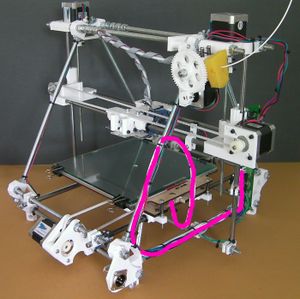

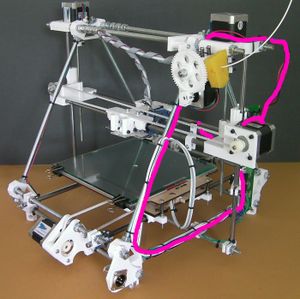

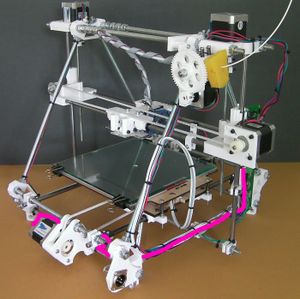

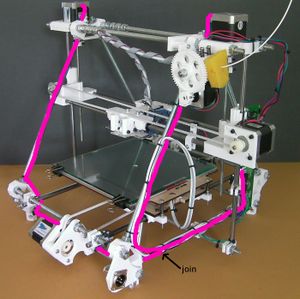

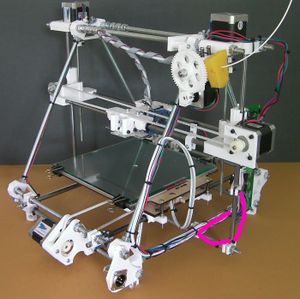

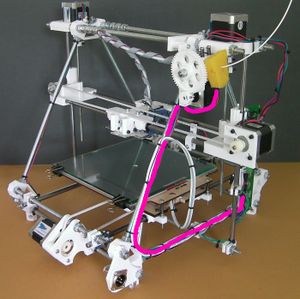

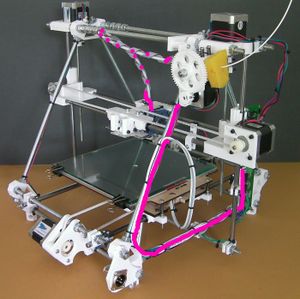

In what follows you will find the routes of the individual connections superimposed on this picture. It is taken from the back of the machine, and the side of the machine on the picture's right is therefore the left side of the machine when it is viewed from the front in its normal working position.

Almost all the wiring runs down the triangle threaded rod to the fore of the picture, and then along the triangle threaded rod at the bottom.

Attaching the control electronics

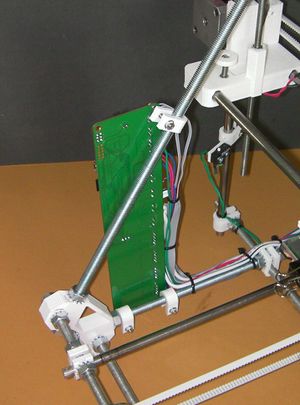

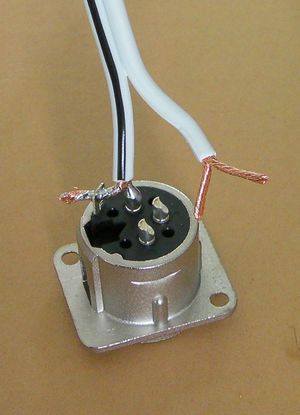

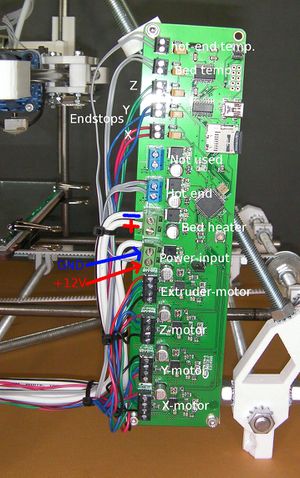

Attach the three U clips to the frame as shown. The controller board goes on the left hand side of the machine at the front (that is, the end of the frame that is on the same side as the XLR power input connector, but at the other end).

Using a sharp blade cut the 3mm internal-diameter plastic tube into three pieces of equal length of about 7mm. These will form spacers between the printed circuit board (PCB) of the controller and the U clips.

Adjust the positions of the U clips so that they line up with the holes in the PCB and the PCB is vertical.

Attach the board to the clips with the screws, washers and nuts. The order goes:

- screw head

- washer

- PCB

- 7mm plastic tube

- U clip

- washer

- nut

Facing the machine from the front, the components on the PCB should be away from the triangle frame and the USB connector and SD card holder should be at the top of the PCB facing you.

The power supply wire

The heated bed wires

The X motor wires

The Y motor wires

The Z motor wires

The X endstop wires

The Y endstop wires

The Z endstop wires

The extruder motor wires

The hot-end wires

Connections to the controller board