RepRapPro Mendel frame assembly

Contents

This page is under construction

Introduction | Frame assembly | Y axis assembly | X axis assembly | Z axis assembly | Heated bed assembly | Extruder drive assembly | Hot end assembly | Power supply | Wiring | Commissioning | Printing | Multi‑colour/multi‑materials | Colour Printing - Slic3r | Colour Printing - RepRapPro Slicer | Maintenance | Troubleshooting | Improvements

| A notice about these instructions! |

|

Since 1st April 2013, the RepRapPro Mendel has been superseded by the RepRapPro Tricolour and Mono Mendel. |

Goal

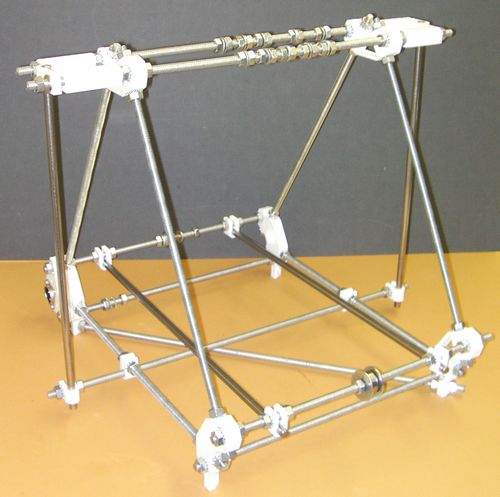

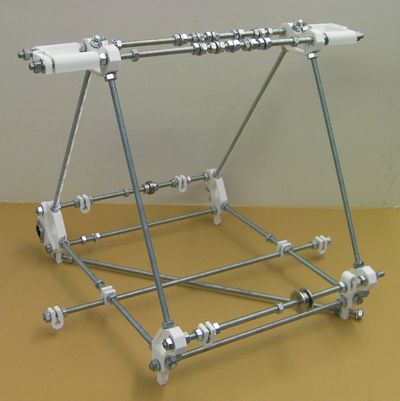

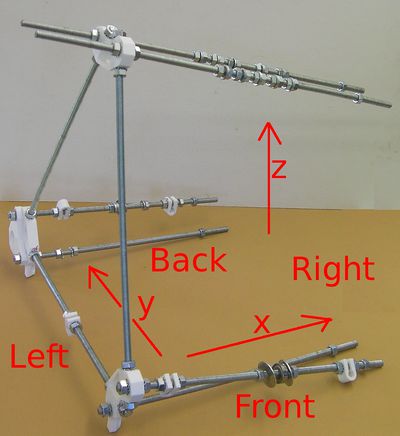

By the end of this stage, your machine should look like this:

Tools

You will need the following tools

- M8 (13mm) spanner

- Adjustable spanner

- 300mm Rule

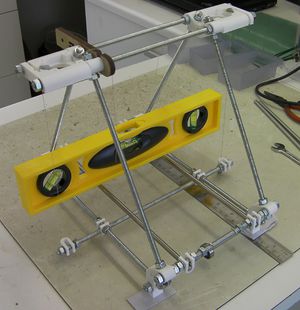

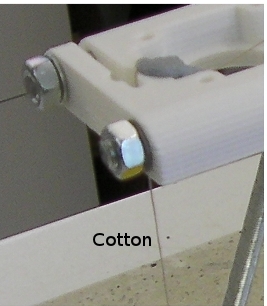

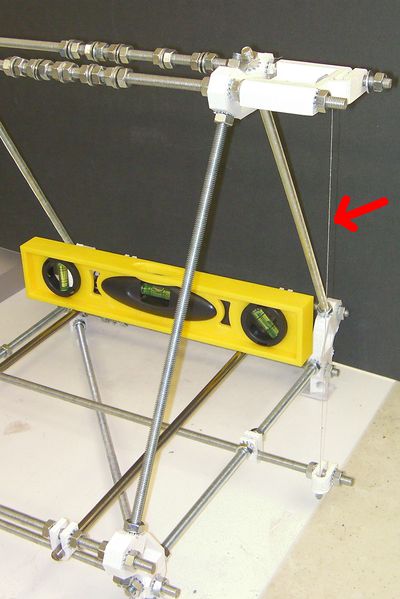

- (optional) Spirit level, cotton and Blu-tack

Step 1: Frame triangles

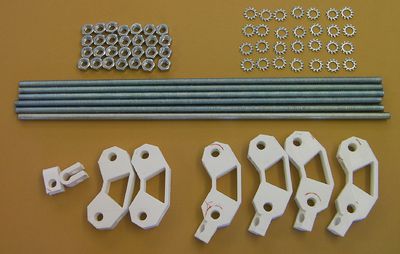

| |

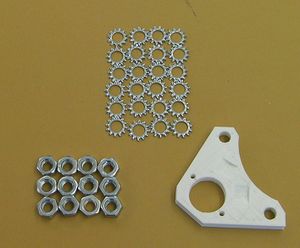

| Item | Quantity |

| 370mm M8 rods | 6 |

| Printed frame vertex with foot | 4 |

| Printed frame vertex | 2 |

| Printed U clips | 2 |

| M8 nuts | 28 |

| M8 lock washers | 28 |

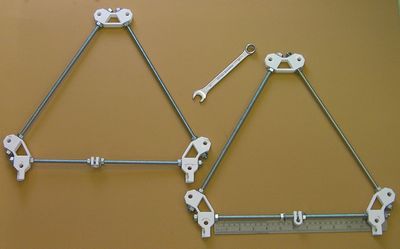

Split the above components into two equal sets, then loosely screw them together into each frame triangle. Make sure you slide a belt clamp along the bottom M6 threaded bars between the frame vertices with feet, with a serrated washer and nut either side. The other nuts should also all have serrated washers under them.

Make the gap between the frame vertices measured face to face next to where the nuts and washers tighten about 290 mm.

Don't tighten anything at this stage.

Step 2: Cross bars

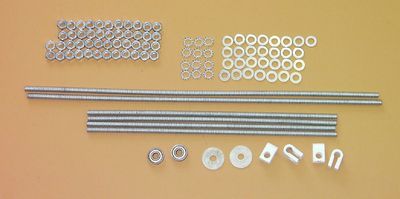

| |

| Item | Quantity |

| 330mm M8 rods | 4 |

| 470mm M8 rods | 2 |

| Printed U clips | 4 |

| M8 mudguard washers | 2 |

| 8mm bearings | 2 |

| M8 lock washers | 8 |

| M8 washers | 29 |

| M8 nuts | 46 |

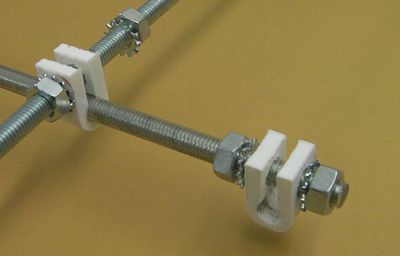

Assemble the bars as shown in this picture:

From top to bottom and left to right the sequences are:

- Nut, nut.

- Nut, nut, lock washer, lock washer, nut, nut.

- Nut, nut, lock washer, U, lock washer, nut, nut, mudguard, washer, bearing, washer, mudguard, nut, nut, lock washer, U, lock washer, nut, nut.

- Nut, nut, lock washer, U, lock washer, nut, nut, washer, washer, bearing, washer, washer, washer, washer, washer, nut, nut, lock washer, U, lock washer, nut, nut.

- Nut, 5x(nut, washer, washer, nut), nut

- Nut, 5x(nut, washer, washer, nut), nut

Take care not to confuse lock washers and ordinary washers.

Step 3: Put them all together

| |

| Item | Quantity |

| M8 nuts | 12 |

| M8 lock washers | 24 |

| Printed XLR panel-plug holder | 1 |

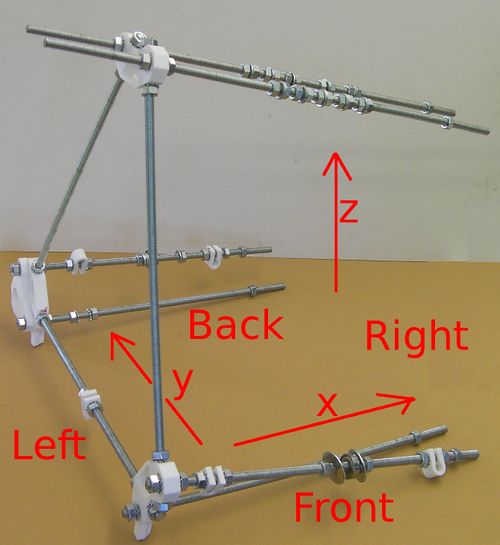

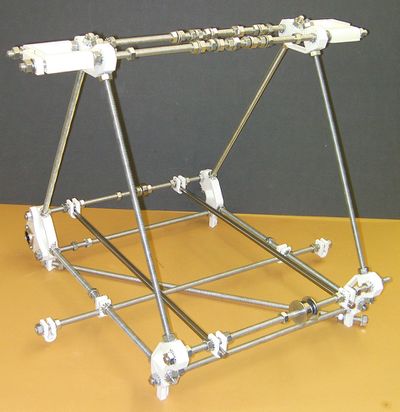

Firstly screw the cross bars into one of the triangles as shown:

This is the moment of what embryologists would call gastrulation: the point at which your RepRap acquires a front, back, top, bottom, left and right - as shown. The x, y, and z coordinate directions of the finished machine are also shown. If you like, use sticky tape to attach small labels to the rods while you are building so you can remember which side and which direction is which.

On the bottom, and using the numbers of the rods from Step 2:

- Back top: Rod 4, with the 5 washers together to the left.

- Back bottom: Rod 2.

- Front top: Rod 3.

- Front bottom (yes - we know this is funny...): Rod 1.

And at the top attach the two long Rods: 5 and 6.

Use two locking washers and a nut on each rod.

The XLR bracket attaches back left. The indentations on it go towards the inside of the machine - they accommodate the washers on the frame.

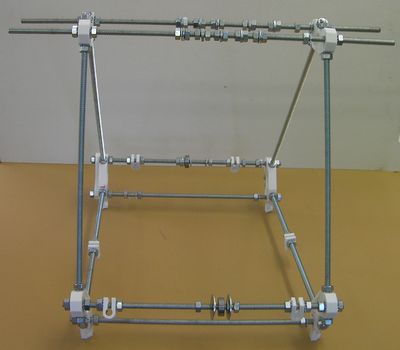

Next screw the second triangle to the other end of the cross bars:

Now go round the frame tightening everything up using two spanners. Tighten the triangles first, then the six bars in the x direction.

Make the gap between the faces of the vertices on the triangles 290mm, as mentioned above. Make the gap in the x direction between the faces of the vertices 273mm.

Get the two top rods even, with an equal amount projecting each side, then move the back one 5mm to the right and the front one 5mm to the left.

Try to get the measurements accurate. But it is more important to get the lengths equal than to get them precise.

You will find that you can make very fine adjustments when things are almost tight by slightly slackening a nut on one side of a join then tightening the nut on the other side.

Step 4: Z-motor mounts and power connector

| |

| Item | Quantity |

| 470mm M8 rods | 2 |

| Printed Z motor holders | 2 |

| Printed U clips | 2 |

| M8 nuts | 12 |

| M8 lock washers | 10 |

| M8 washers | 6 |

| XLR panel plug | 1 |

| 12mm M3 caps | 2 |

| M3 washers | 2 |

| M3 nuts | 2 |

Put the two U clips already on the frame roughly in the middle of their bars, then push one of the 470mm rods through. You may have to twist it, using its thread to move it - it can be quite a snug fit. Use nuts and lock washers to put two more U clips on its ends, as shown. Leave all these lose:

Next thread the base diagonal rod through two of the four feet. Put nuts and lock washers on it, but leave them lose.

Put four smooth washers on the top bars, then put the Z motor mounts on as shown. Secure them with two nuts each, with one smooth washer and one lock washer. The smooth washer goes on the clamp that will hold the Z rods. Tighten the other nuts against their lock washers, but leave the Z-rod-clamp nuts lose:

Fit the XLR plug using the M3 screws, nuts and washers. The washers go under the nuts. Fit the plug so that the triangle formed by its three pins points upwards.