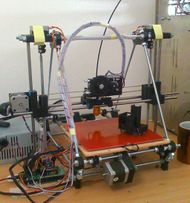

Prusa Mendel

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: working

| Description | Prusa Mendel is simpler remix of normal Mendel.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Also see SAE Prusa Mendel if you are building this machine using SAE (Imperial) Fasterers

The Prusa Mendel is a simpler remix of the original Mendel. I wanted to use bushings instead of regular bearings. The current prototype is using two bearings in total, one for X and one for Y axis.

I have the entire machine up and running, with my printed PLA bushings. It's pretty smooth.

<videoflash>tyVM3-v84I0</videoflash>

Contents

Development

The development of the Prusa Mendel is hosted on github: http://github.com/prusajr/PrusaMendel

You can follow the changes on Changelog

You can sign up for github for free and fork the project to begin working on it.

History

Bill of Materials

The Prusa Mendel BOM is included in the Prusa Mendel README on GitHub here: Prusa Mendel Bill of Materials

(in works, not complete yet)

Printed Parts

6x frame-vertex RP 2x coupling RP 3x endstop-holder RP 1x x-carriage RP 1x x-end-idler RP 1x x-end-motor RP 1x y-motor-bracket RP 2x z-motor-mount RP 4x belt-clamp RP 8x bar-clamp RP 2x rod-clamp RP 2x pulley RP

Printed Bushings

1x pla-bushing RP-PLA (makes 12)

Guesstimate of other parts: ("vitamins")

80x M8 nut Fastener 76x M8 washer Fastener 3x 608 Bearing Bearings 6x M8x370 Stud side Studding 4x M8x294 Stud end Studding 3x M8x440 Stud top, Z bottom Studding 2x M8x210 Z-Leadscrew Studding 2x ~8x495 X-bar Bar 2x ~8x406 Y-bar Bar 2x ~8x330 Z-bar Bar 1x 225x225 Print bed Thick Sheet 1x 140x225 Print bot. Thick Sheet 3x ??? Optoflags Thin Sheet 20x M3x?? for motors+pul. Fastener 16x M3 washer " " Fastener 10x M3x10 for X-ends Fastener 8x M4x15 for X&Y-belts Fastener 16x M4 washer " " Fastener 8x M4 nylock " " Fastener 3x M4x?? for X&Y-bearings Fastener 3x M4 Mudwashers " " Fastener 16x M4 nylock " " Fastener 4x M4x?? for Z-Clamps Fastener 8x M4 washer " " Fastener 4x M4 nylock " " Fastener 4x M4x30 for Print bed Fastener ?x M? washer " " Fastener ?x M? nylock " " Fastener

1x standard Mendel extruder

5x Nema 17 NEMA Stepper 1x standard Mendel electronics or Mendel alternative electronics.

(The Prusa Mendel uses the 4 drivers in the standard Mendel electronics package to drive 5 motors by using "two steppers wired in parallel to one driver"[1]).

Printed Parts

Printing a Prusa on a Mendel

An easier option then individually printing each part if you are printing Prusa on a RepRap Mendel is the pre-assembled build file containing the Prusa parts. With this option you only need to print the Mendel plate and the PLA bushings to get a complete Prusa Mendel:

- Mendel Plate (contains all printed parts except the PLA Bushings)

- PLA Bushing

Printing a Prusa on a CupCake CNC

There are also pre-assembled build files available to fit your CupCake CNC's build area (download using right click => save as)

Note:

- These plates use the full surface of the build platform, so remove bolts if necessary.

Plates for the MakerBot:

- Makerbot Plate 1=> 6 hrs 30 min

- Makerbot Plate 2=> ~2 hrs 30 min (needs retesting)

- Makerbot Plate 3=> 5 hrs 40 min

- Makerbot Plate 4=> 2 hrs 30 min

- Makerbot Plate 5 => 1 hr 50 min

Printing a Prusa on anything else

Last but not least, if you have a machine that doesn't fit into any of the previous options all the .stl files necessary to print a Prusa Mendel are available on the PrusaMendel Github where you can download them and print them individually.

Assembly

This section is work in progress.

Assembling the frame

Assembling the frame vertex triangles (2x)

There is a triangle on each side of the Prusa RepRap, you will need to make 2 of these and then connect them together (see next step) to form the Prusa frame. Each side is an equilateral triangle with a frame vertex on each corner. You can use either footed or non-footed vertices to build this (the footed ones look better, but are not critical.) The instructions assume you are using footed vertices.

Parts Required (per triangle)

- 2 RP footed frame vertices

- 1 RP frame vertex (non-footed)

- 1 RP bar clamp

- 3 370mm M8 threaded rods

- (optional but recommended)A piece of threaded rod or wood or any other material with precisely 290mm length. This is your frame jig.

Instructions

- Take one of the 370mm threaded rods, and slip a washer onto the middle of it.

- Take the RP bar clamp (the U-shaped bit with the two holes) and slide the threaded rod through the two holes until the clamp sits next to the washer.

- Slide another washer onto the rod from the other side.

- Thread two nuts onto either side of the clamp, until they are next to the washer, but do not tighten them yet.

- Thread another two nuts on each side of the rod, followed by washers. See the picture for what it should look like.

<flickr>5188262096|thumb|right|m|The bar clamp on the threaded rod.</flickr>

- Slide the rod through the long bottom (footed) side of two vertices. Make sure the feet point in the same direction. Also make sure the bulge on the non-footed side of the vertex points outwards.

- Measure the distance. The distance between the two vertices should be 290mm (along the rod). Get it approximately right now, we will check this again later. If you have a frame jig, place it between the two vertices and adjust the nuts until you can just barely fit the jig between them.

- Place another washer and nut on the other side of the vertex. Tighten, but not too much. We'll need a bit of flexibility here still.

- Take another 370mm M8 threaded rod and place a nut followed by a washer at each end.

- Place one end of the threaded rod into the one of the two footed frame vertices. It should be in the same plane as the first threaded rod. fix it in place with a washer and nut. You should now have two sides of the equilateral triangle.

- Take the third piece of threaded rod and put a nut and washer on each end. Place it in the other footed vertex and fix it in place with a washer and nut. You should now have a triangle of threaded rods with two footed vertices on two of the corners, nothing in the third corner, and a bar clamp between the two vertices.

- Take the third vertex (non-footed) and slide it onto the threaded rods in the final corner of the triangle. Measure the lenghts of the three sides to make sure they are all 290mm long (along the rod from plastic part to plastic part). Adjust the nuts to make sure this is so. Use the frame jig if you have one. Once done, place a washer and nut on the top of the vertex. Tighten all the outer nuts.

- You should now have a sturdy triangle with equal-length sides, two feet on the bottom, and a bar clamp between the feet. Adjust the nuts around the bar clamp (but do not crush the bar clamp together yet) until it's approximately in the middle of the rod. Leave the nuts there loose. See photo for what you should have at this point.

<flickr>5188259098|thumb|right|m|The finished frame triangle.</flickr>

- That's it, that's one of the triangles done. Repeat the entire procedure for the second triangle. It is exactly identical to the first.

(I have a pic of the assembled vertices) (please post it then!)

Now we need to connect the 2 frame triangles to form the Prusa RepRap frame.

Assembling the top threaded rods

These connect the 2 frame triangles at their tops as well as providing mounts for the z-axis motors.

Parts Required

- 2 assembled frame vertex triangles (see previous step)

- 2 z motor mounts

- 2 threaded rods (TODO: length)

Instructions

- attach the tops of each frame triangle (that is the non-footed vertex) to the threaded rod using a nut on each side of each hole to loosely keep them in place (we will adjust the position of these later).

- take the z motor mounts and attach them to the outsides of each non-footed frame vertex using a nut on each outer hole.

Assembling the front threaded rods

<flickr>5187662877|thumb|right|m|The front threaded rods assembly.</flickr>

These 2 threaded rods are used to connect the front/bottom vertex of each triangle as well as the y-stage bars and y motor mount to the frame.

Parts Required

- 2 assembled frame vertex triangles

- 2 universal rod clamps

- 1 y motor mount

Instructions

Assembling the rear threaded rods

These 2 threaded rods are used to connect the back/bottom vertex of the 2 triangles together as well as the y-stage bars and belt pulley.

Parts Required

- 2 assembled frame vertex triangles

- 2 universal rod clamps

- 1 y motor mount

Instructions

- Loosely attach the pulley to the center of the rod using 2 pairs of nuts and washers to keep it in place.

- Loosely attach the 2 universal rod clamps to either end of the rod using 4 nuts. Do not attach these using the 'U' clamping area, instead use the holes on either side of the 'U'. We will need the clamping 'U' later on to attach the y-stage bars.

- Loosely attach the rod to the upper hole in the 2 front frame vertices and attach the unused rod to the lower hole.

Tightening the frame

Now that the frame is fully assembled we can adjust and tighten each of it's threaded rods.

Instructions

- Adjust each of the threaded rods according to the diagram bellow and then secure them in place by tightening their nuts with a wrench until they are strongly attached (but not so tight that you see the plastic deform).

(TODO: Diagram)

Assembling the z stage

Parts Required

- 2 shaft couplers

- 2 PLA bushings

- 2 stepper motors

- 2 threaded rods (TODO: size)

- 2 smooth rods (TODO: size)

- 1 prusa frame (see previous step)

Instructions

Assembling the y stage

Parts Required

- 4 PLA bushings

- 1 belt clamp

- 2 smooth rods (TODO: size)

- 1 y timing belt

- 1 stepper motor

Instructions

Assembling the x stage

Parts Required

- 4 PLA bushings

- 2 smooth rods (TODO: size)

- 1 x timing belt

Media

- Two printers simultaneously - Prusa and shaper cube working side by side.

- Prusa homing using enstops

- Prusa development overview

- Prusa Y axis stress test

- Prusa Z axis stress test

- Early preview of the Prusa Mendel redesign

- Fumon's Prusa build session 1 - D1plo1d building Fumon's Prusa Mendel at Hacklab.to. Should give a hint as to how the Prusa Mendel parts go together.