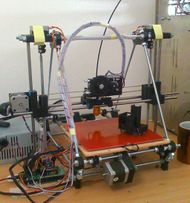

SAE Prusa Mendel

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: working

| Description | SAE Prusa Mendel is an offshoot of Prusa Mendel.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

SAE Prusa mendel is an offshoot of the Prusa Mendel, only difference currently is it only uses 1 screw size (SAE #6 instead of metric M3 and M4), and only uses 608 bearings. Spacexula did the conversion, and is currently trying to maintain this branch.

<videoflash>tyVM3-v84I0</videoflash>

Contents

Development

The Prusa Mendel is on hosted github: http://github.com/prusajr/PrusaMendel

You can follow the changes on Changelog

You can sign up for github for free and fork the project to begin working on it.

History

Bill of Materials

The SAE Prusa Mendel BOM is slightly different than Metric Prusa Mendel, but as close as possible.

(in works, not complete yet)

Printed Parts

| Quantity | Description | Type | Comments | Diagram | Dwg |

|---|---|---|---|---|---|

| 2 | coupling | RP | |

||

| 3 | endstop-holder | RP | |||

| 1 | x-carriage | RP | |

||

| 1 | x-end-idler | RP | |

||

| 1 | x-end-motor | RP | |

||

| 1 | y-motor-bracket | RP | |

||

| 2 | z-motor-mount | RP | |

||

| 4 | belt-clamp | RP | |

||

| 8 | bar-clamp | RP | |

||

| 2 | rod-clamp | RP | |

||

| 2 | pulley | RP | |

||

| 4 | frame-vertex with foot | RP | |

frame-vertex-foot.dwg | |

| 2 | frame-vertex | RP | |

||

| 12 | pla-bushing | RP-PLA | check your build file, the file makes either 4 or 12 | |

Non-Printed Parts ("vitamins")

| Quantity | Description | Type | Comments | McMaster Part Numbers[1] |

|---|---|---|---|---|

| 1 box (100) | 5/16" nuts | Fastener | 95462A030 or 90490A030 (1 box) | |

| 1 box (100) | 5/16" washers | Fastener | Washers are produced with various tolerances so it is recommended that if buying 5/16" washers, one should check that they do not rub against the outer race of the skate bearings. If one can find 1/4" washers that can fit over 5/16" rod (fairly common), those should be used instead. | 90126A030 (1 box) |

| 1 box (100) | #6 washers | Fastener | 90126A509 (1 box) | |

| 1 box (100) | #6 1" screws | Fastener | 90272A153 (1 box) | |

| 1 box (100) | #6 nylock nuts | Fastener | 90631A007 (1 box) | |

| 1 box (100) | 5/16" Fender Washers | Fastener | You only need 6 | 91090A111 (1 box) |

| 3 | 608 Bearing Sets | Bearings | Here is a nice explanation of bearing types and what the numeric codes and suffixes mean. For example ZZ suffix means double shielded, whereas 2RS would mean double sealed | (any 608ZZ shielded bearing (Mendel Bearing Kits) such as: this or this) - 5972K91 is not a good choice as it is unshielded & $$$$ |

| 1 box (100) | M3x10 bolt | Fastener | Motor Mounting | 92005A120 (?) |

| 2280 mm ~90"/7.5' | Neoprene Belting .200" Pitch, 1/4" | Drive Belt | This is not compatible with the T5 pulley in the git repo (see below) | 7959K24 (?) |

| 1 | 5/16" 9 foot smooth rod (NOT GALVANIZED) | X,Y,Z bars | 8890K41 (3 foot sections, $4.05, 0.005"/foot straight)

8893K41 (3 foot sections, $4.30, no straightness spec, one arrived bent) 8888K41 (3 foot sections, $8.53, 0.005"/foot straight) All are +/-0.0005" and may bind on bronze bushings if oversize These are all ground rods (typically called "Drill Rod" in the US and "Silver Steel" in some other parts of the world), and all make excellent choices for your XYZ rods. The more expensive ones offer no practical benefit, but are listed in case the first option is out of stock. You can also substitute stainless steel rods, but they are generally not quite as smooth, and they will usually be more expensive. Plain steel and galvanized rods are poor choices due to the rough surface finish. Note: Each of the above parts are annealed, and are typically hardened prior to use. Which means, as they are delivered to you, they are soft, bendable, and machinable. Hardening it will dramatically increase the stiffness of the metal. The primary difference between the three above is method of hardening, "air", "oil", or "water". If you intend to harden it, oil hardening is very reproducible and can be reversed easily as well. | |

| 1 | 5/16" 21 foot threaded rod | Frame | 98841A030 (3 foot sections) | |

| 4 | 7/16" x ~1" springs | optional, or from a spring loaded pen | ||

| 1 | Wade's Geared Extruder | (or any other compatible extruder) | ||

| 5 | NEMA 17 Stepper motors | |||

| 1 | Standard electronics + endstops | Should meet RepRap Interface Standard #RIS 1. |

Aquiring Drive Belts

(No need to split belts, no continuous Z axis belt)

Belt 1- 870mm ~34.25"/ 2.8' Belt 2- 1410mm ~55.5"/ 4.7'

The 0.2" pitch XL belts are very close in pitch to the T5 metric belt (5mm = 0.197") so the XL belt will run on a T5 pulley. The ratio of tooth to gap size is different and the T5 pulley (such as the one in the Prusa git repo) will have backlash as each time the pulley reverses the small XL tooth will slide in the larger T5 gap of the pulley before it starts moving. If you use XL belts print an XL pulley such as the one on Thingiverse (If you use this pulley, you will need some M3 nuts and M3 grub/set screws as SAE screws/nuts will be too big) or MakerGear Prusa github repository.

You will need to adjust the X/Y_STEPS_PER_MM in your firmware to match XL pitch.

Acquiring Smooth Rod

Do not get Galvanized Rods, they are much rougher. Drill rod (also called tool steel or silver rod) is smoother and made to tighter tolerances. Look for a straightness tolerance if mail-ordering (e.g. 0.005"/foot) or order extra and be prepared to cut around bent sections.

If you want to use bronze (also called brass or oilite) bushings in holders note that even drill rod spec is +/-0.005 while bushings are +0.0010/-0, so an oversized rod will not work smoothly with a bushing. Precision ground rods are +0/-0.0003 and work much better with bushings. 8mm precision ground rod is cheaper than 5/16" so going with an 8mm smooth-rod system makes sense with bronze bushings. VXB Bearings has 8mm rods in 495mm, 406mm and 330mm which are suitable.

Use Standard Mendel lengths for cutting 420x2 406x2 and 330x2.

The smooth rod is cut into varying lengths, therefore, its common to acquire in 3 foot sections.

If you have 3x 3ft smooth rod 8893K41

Rod1: 420mm,350mm 16.5",14" Rod2: 420mm,350mm 16.5",14" Rod3: 406mm,406mm 16",16"

Acquiring Threaded Rod

The rods should be cut (by you) to the following sizes, in mm (the original sizes) or in inches for the SAE purist who wants to avoid little bits at the end.

The lengths of threaded rod available (and practical to get home) vary. Most places seem to stock 3' lengths; Lowes in some towns have 4' lengths and Menards or Ace Hardware also offer 6' lengths. Below are three cutting lists that attempt to fit the required parts into the various rod lengths. To the right are "close enough" lengths in inches that will minimize the number of cuts and avoid awkward left over pieces. If the list includes a 19" piece this should be used for the Lower Z brace.

(Note: Cut one of the threaded rod sets listed below, not all!)

7x3 ft lengths. This requires 12 cuts and leaves 3 extra pieces (6",12",21")

3' Rod1: 440mm,440mm 18",18" 3' Rod2: 440mm,370mm,50mm 19",15",2" 3' Rod3: 370mm,370mm 15",15" +6" extra 3' Rod4: 370mm,294mm,210mm 15",12",9" 3' Rod5: 370mm,294mm,210mm 15",12",9" 3' Rod6: 294mm,294mm 12",12" +12" extra 3' Rod7: 370mm 15" +21" extra

3x4 ft and 2x3 ft lengths. This requires 12 cuts and leaves just one extra piece (3")

3' Rod1: 440mm,440mm 18",18" 3' Rod2: 440mm,370mm,50mm 19",15",2" 4' Rod3: 370mm,370mm,370mm 15",15",15" +3" extra 4' Rod4: 370mm,294mm,294,210mm 15",12",12",9" 4' Rod5: 370mm,294mm,294,210mm 15",12",12",9"

3x6 ft lengths. This requires 14 cuts and leaves just one extra piece (4")

6' Rod1: 440mm,370mm,370mm,294mm,294mm 18",15",15",12",12" 6' Rod2: 440mm,370mm,370mm,294mm,294mm 18",15",15",12",12" 6' Rod3: 440mm,370mm,370mm,210mm,210mm,50mm 18",15",15", 9", 9", 2" +4" extra

The inch measurements above are approximations that reduce the number of cuts.

Closer translations ( +/1 1.5mm) are:

17 3/8" (Top Z braces and Lower Z brace) 14 5/8" (Triangle vertices) 8 1/4" (Bottom X braces)

About the Electronics

The Prusa Mendel uses the 4 drivers in the standard Mendel electronics package to drive 5 motors by using "two steppers wired in parallel to one driver" [2].

Where To Purchase

See the Mendel Buyers Guide for information on where to purchase all of the parts needed.

Printed Parts

Printing a Prusa on a Mendel

An easier option then individually printing each part if you are printing Prusa on a RepRap Mendel is the pre-assembled build file containing the Prusa parts. With this option you only need to print the Mendel plate and the PLA bushings to get a complete Prusa Mendel:

- BROKEN SAE Mendel Plate (contains all printed parts except the PLA Bushings)

- SAE PLA Bushing

Printing a Prusa on a CupCake CNC

There are also pre-assembled build files available to fit your CupCake CNC's build area (download using right click => save as)

Note:

- These plates are 85x95mm in size.

Plates for the MakerBot (The plates have changed, these print times are no longer accurate):

- SAE Makerbot Plate 1=> 6 hrs 30 min

- SAE Makerbot Plate 2=> ~2 hrs 30 min (needs retesting)

- SAE Makerbot Plate 3=> 5 hrs 40 min

- SAE Makerbot Plate 4=> 2 hrs 30 min

- SAE Makerbot Plate 5 => 1 hr 50 min

Printing a Prusa on anything else

Last but not least, if you have a machine that doesn't fit into any of the previous options all the .stl files necessary to print a Prusa Mendel are available on the PrusaMendel Github where you can download them and print them individually.

Buy the printed parts

Mendel_Buyers_Guide#RepRapped_Parts_Kits

Assembly

Assembly of an SAE Prusa Mendel should proceed in exactly the same order as the original Prusa Mendel. Consult the Prusa Mendel Assembly Guide for more information.

Media

- Two printers simultaneously - Prusa and shaper cube working side by side.

- Prusa homing using enstops

- Prusa development overview

- Prusa Y axis stress test

- Prusa Z axis stress test

- Early preview of the Prusa Mendel redesign

See Also

- PLA bushings

- SAE Mendel

- [3] MrJohn's cost breakdown