Columbus

Release status: unknown

| Description | Documentation of Columbus R&D

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Columbus is a 3D printing device that is being developed to answer the inspiring challenges of the Kartik M. Gada Personal Manufacturing Prize. The current stage of development is: preliminary design. In this stage brainstorming sessions are combined with due diligence to narrow down goals and define objectives. Various materials are extruded by Columbus via a Cartesian arrangement which consists of a belt driven gantry for positioning in the X & Y axises and a print bed that is raised and lowered by a linkage for positioning along the Z axis.

Contents

Overview

//Under construction, more coming soon!

"This web-page, therefore, is about making a useful virus that is as big as a fridge." -Adrian Bowyer, Wealth Without Money, 24 Feb 2006

//More on that concept to come.

The main requirements of the Gada Prize are:

- Print at least three different materials, including one that is usefully electrically conductive.

- Demonstrate the ability to print electronic circuit boards.

- Any print beds must be of a material which may be reused with minimal refurbishment for at least 20 print cycles.

- Maintain a total materials and parts cost under $200.

- 90% of the volume of the device's components shall be printed.

- Demonstrate a build volume greater than 300mm[11.81in] x 300mm[11.81in] x 100mm[3.94in].

- The capacity to print a full set of components for a complete replica of itself within 10 days unattended save for clearing no more than one printer head jam.

- The ability to print autonomously without a PC attached.

- Uses no more than 60 watts of electrical power.

Columbus Specifications

The table below outlines the specifications of the machine.

| Metric[Imperial] | |

|---|---|

| Manufacturer | Anyone |

| Model | Columbus |

| Technology | FFF (Fused Filament Fabrication)/Thermoplastic extrusion |

| Price of all materials | TBD |

| Annual Service Cost | TBD |

| Size | 400mm[15.75in] x 400mm[15.75in] x TBDmm[TBDin] |

| Weight | TBDkg[TBDlbs] |

| Build Envelope | 300mm[11.81in] x 300mm[11.81in] x TBDmm[TBDin] |

| Materials | TBD |

| Material Cost | TBD |

| Speed | TBD |

| Accuracy | TBD |

| Finish | TBD |

| Volume of printed parts to replicate | TBD |

Design Philosophy

//Under construction, more coming soon!

"Truth and beauty...are almost like the ideal conjoined twins that a scientist would want to date." -David Bolinsky, David Bolinsky Animates a Cell, Mar 2007

//More on that concept to come:)

- Required reading:

- Wealth Without Money, Adrian Bowyer

- The Self-replicating Rapid Prototyper ─ Manufacturing for the Masses, Adrian Bowyer

- Required viewing:

- David Bolinsky Animates a Cell, David Bolinsky

- Rose Lovegrove Shares Organic Designs, Ross Lovegrove

Design Tree

- Preliminary Design

- Prototype One

- Redesign One

- Prototype Two

- Redesign Two

Key Concepts

Progressive Construction

It is assumed that those who assemble Columbus will be in one of two main categories: those that have an existing 3D printer (i.e. Darwin, Mendel, MakerBot, RapMan) and those that do not. While it will be difficult to achieve the $200 price range with an existing 3D printer, it will be nearly impossible to reach that goal without such a device. In an effort to increase the number of potential users Columbus is being designed with a "progressive construction" in mind. In this scheme the user will first assemble a RepStrap which contains many of the components of the full size Columbus (i.e. stepper motors, electronics, straight rods). This device will then print the remaining structural components. Finally, the initial device is dismantled and it's components are combined with the parts it printed to form the compete Columbus printer. It is hoped that this routine will not only save the first time user money, but will also familiarize the user with the components and construction ideas they need before assembling the complete unit.

Structure

Print Bed

Control Systems

Workbook

General Notes

In accordance with the official Gada Prize rules regarding documentation and transparency - as interpreted by the RepRap Core Team and others - all documentation for this project will take place here in this wiki. If there happen to be any "Other Spaces" out there that have documentation for this project, then such information is posted there only after it is posted here.

- The following notes help to keep this workbook in a neat and orderly condition and shall be generally adhered to throughout all levels of documentation.

- All dimension and temperature nomenclature shall include both SI and Imperial units. SI units shall be first followed by Imperial units in brackets. Examples: 100mm[3.94in] and 40°C[104°F]

August 2010

8 AUG '10

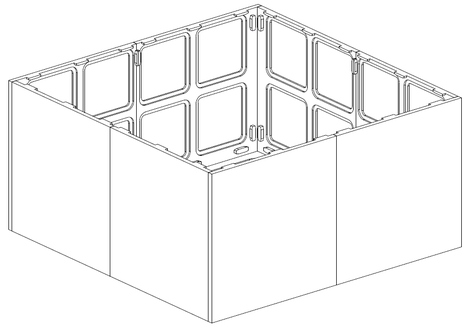

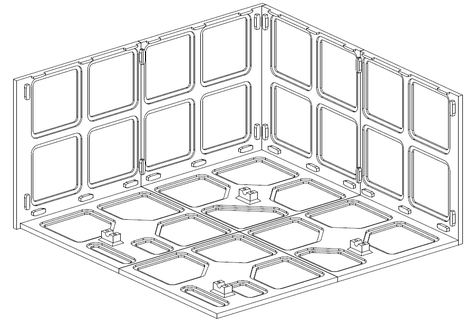

- Over the last two years I have followed the RepRap movement with particular interest. However, it took the Foresight Institute's act of throwing down the gauntlet with the Gada Prize before I finally got involved with this awesome community of builders. For the last two weeks I have been thinking a lot about how to make the structure of a 3D printer 100% "printable". I decided that my design needed to free up as much internal volume as possible. In order to do this I brought the load bearing members as far away from the center of the machine as possible, thus forming an exoskeleton-like enclosure. I have designed several panels that can be linked together with printable fasteners (more on those in the future). See the following images:

- Note that the panels are pocketed to reduce the amount of print material. This is only a preliminary design, I haven't done any stress analysis yet. Please leave a comment or ask a question in Columbus's discussion page. --Isaac Olson 04:07, 9 August 2010 (UTC)