组装Y轴

介绍|搭建框架|组装Y轴|组装X轴|组装Z轴|组装热床|挤出机组装|热端组装|电源|布线|调试|打印 多颜色/多材料|维护|故障排除|改进

目标

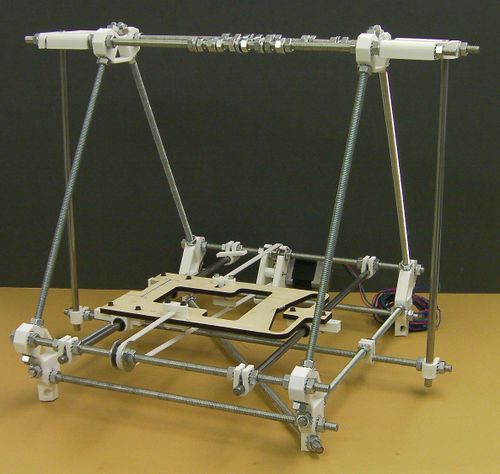

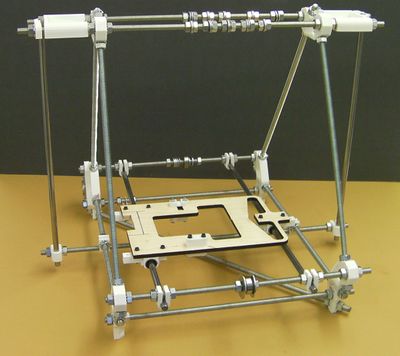

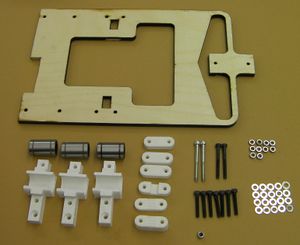

在这个阶段的最后,你的机器将会像这样:

Tools

你将使用到以下工具:

- M8 (13mm) 扳手

- 可调节扳手

- M3 内六角扳手

- M3 六角固定螺丝

- M3 扳手

- 尖嘴钳

- 侧铣刀

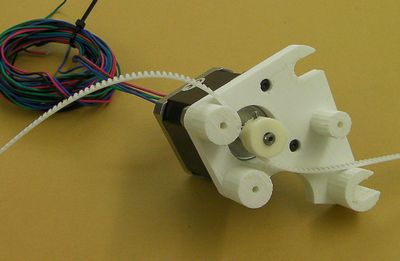

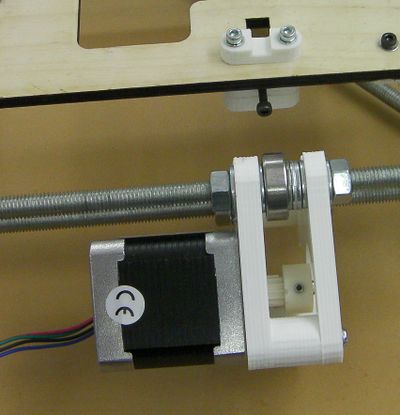

第一步:Y电机安装

| |

| 物品 | 数量 |

| 打印的Y电机箱(底座) | 1 |

| 打印的Y电机盖 | 1 |

| Nema 17 电机 (如下) | 1 |

| M3 x 35mm 螺丝 | 3 |

| M3 x 10mm 固定螺丝 | 1 |

| M3 螺母 | 1 |

| M3 x 8mm 螺丝 | 2 |

| M3 垫圈 | 3 |

| 模压齿滑轮 | 1 |

套件中包含4个Nema17电机和一个Nema14电机,小的那个是用来驱动挤出机的。

后面的Mendel版本套件中的打印齿滑轮如下图:

这可以很简单的和电机轴连接,具体如下

使用两个短的螺丝把它安装在电机上,大约插入电机轴的一半左右:

线从电机底部出来,如图所示。

如果你有一个成型轮,将固定螺丝旋入带齿的皮带轮。注意的是不要穿过螺纹,塑料是不坚硬的。把螺丝旋紧,使其穿过那个洞,并不再深入,将塑料中间孔中多余的塑料去除,然后把滑轮放在电机轴的最外侧重心,如图所示。使用带齿皮带使得沿轴的距离正确。通过轴平面对齐固定螺丝,然后旋紧它。 不要旋得太紧 -在滑轮内部嵌有螺母,如果旋得太紧的话,它将会导致滑轮破裂。

如果你有打印好的滑轮,将他放在轴上。它将是正好牢固的,也许你需要调整它到合适的位置,使用软锤或者木块。你如果在滑轮上放置一个管子,将安装在电机轴上,你可以轻轻敲打来调整滑轮的位置。握住电机轴,而不是电机的身体,然后从另一端轻轻敲打。如果你喜欢的话,你可以通过一滴胶水固定(但是要确保轴上完全没有胶水)。 注意避免 胶水接近轴在电机上的连接口。

使用剩下的螺丝,垫圈和螺母安装另一半安装笼。其中有放置螺母的凹槽,可以很紧密的结合。当把螺母放进凹槽,旋紧事,注意六角形螺母要对准六角形凹槽。

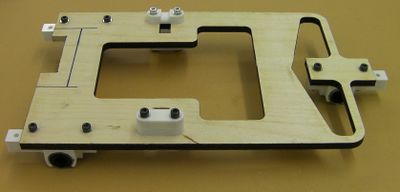

第二步:Y蛙台

备注:英文原称为Y frog,斗胆称其为蛙台,若有相对应的专业术语,还望替换。

| |

| 物品 | 数量 |

| 激光切割的蛙台 | 1 |

| LM8UU 轴承 | 3 |

| 打印的轴承架 | 3 |

| 打印的7mm粗皮带夹 | 3 |

| 打印的皮带导向器件 | 1 |

| 打印的4mm厚皮带扣 | 1 |

| 打印的12mm厚皮带调节器 | 1 |

| M3 x 40mm 螺丝 | 2 |

| M3 x 35mm 螺丝 | 2 |

| M3 x 20mm 螺丝 | 7 |

| M3 尼龙自锁螺母 | 1 |

| M3 螺母 | 10 |

| M3 垫圈 | 20 |

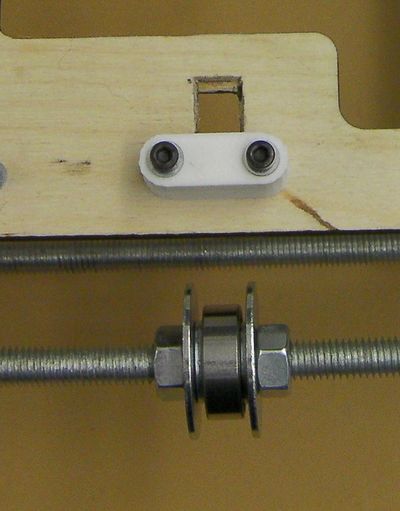

使用20毫米螺丝,螺母和垫圈将轴承架安装在激光切割部件上。不要旋紧螺母:

将轴承插入轴承夹 ,方向按照 右图所示。 不要试图反过来。轴承应该很紧密的固定,如果它们有一些松动以后,在松动的轴承周围包裹上两三圈聚酰亚胺胶带(kapton tape)。使它保持平整没有皱纹以及气泡。

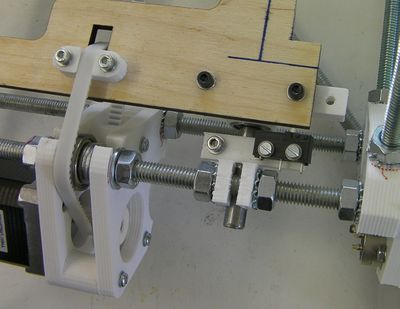

安装皮带夹:

图中远处使用的是40毫米螺丝。图中从上往下的顺序是:

- 皮带导向器件(在图中对着你的是弯曲部分)

- 激光切割的蛙台(如图所示)

- 张紧器(在图中六角形凹槽对着你,手柄端向下)

- 7mm 厚的夹子

图中近处的使用的是35毫米的螺丝,由下往下的顺序是:

- 7mm 厚的夹子

- 4mm 厚的皮带夹

- 激光切割的蛙台

- 7mm 厚的夹子(仅仅是用来分担负荷)

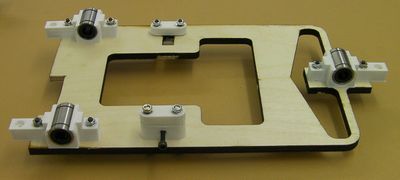

下图为上图翻转以后的图,可以查看上图中被隐藏起来的细节:

将尼龙自锁螺母放在张紧器的六角形凹槽中,然后轻轻的把螺丝放入其中。通过调节这个螺丝将可以绷紧皮带。

然后把蛙台安装在机器上:

W机器正对着你, 松弛右手边的螺母 ,握住Y轴光滑杆上的U形夹,如果你固定左手边的螺母,你可以重新固定光滑杆在同样的位置,确定你这么做了。

滑动连接棒,面向机器的背部。使Y蛙台穿过。

重新在U形夹中放置光滑杆,并且旋紧右手边的螺母。

旋紧M3螺丝和螺母(用来固定)蛙台。

检查蛙台可以完全自由的前后滑动。如果它在一侧末端很紧,那么连接棒是不平行的。如果它在两端都很紧,中间很松的话,那么连接棒的距离太近或者太远。在这两种情况下,分别在两个末端以及中间,测量连接棒的距离(应该是如前面所要求的175毫米,记住那个测量模板),使得一切正确仅仅通过调节 右手侧的连接棒。

Step 3: The Y belt

| |

| Item | Quantity |

| Toothed belt | see below |

| Printed XY endstop holder | 1 |

| microswitch | 1 |

| M2.5x16mm screws | 2 |

| M2.5 washers | 4 |

| M2.5 nuts | 2 |

| M3x20mm screw | 1 |

| M3 washers | 2 |

| M3 nuts | 1 |

Note that the X and Y axis endstop holders are identical, and you want one of those. The Z endstop holder has a longer leg.

Use the full length of toothed belt with your kit to fit this together. You will cut it to the right length when you have finished this step.

Bend the lead on the microswitch as shown in the picture above.

Fit the Y motor and mount:

Adjust its position so that the middle of the bearing is opposite the belt-tensioning screw on the frog. You will find that for this and the idler below you can put your eye level with the frog and line up the middle of the bearings with the belt guide on the frog.

Tighten the four M8 nuts that hold the Y motor mount, taking care that the distance from the left-hand top and bottom nuts to the corresponding nuts on the frame vertices are the same.

Tighten the Y-belt idler:

Line the bearing up to match the belt clamp on the frog.

If you have done everything right so far, the belt tensioner on the frog should be towards the back of the machine.

Put one end of the belt between the bottom clamp on the tensioner and the tensioner part with the nylock nut in. Have the free length of the belt pointing towards the front of the machine. Position the belt so that its teeth lock with the indentations in the tensioner. You should be able to feel this as you move the belt.

Run the belt up through the hole in the frog, and fold it back in the groove in the belt guide. Get the belt square and central in the guide and clamp, then tighten the M3 screws and nuts that retain it. These need to be tight, but not so tight that they bend the clamp.

Run the belt over the bearing above the motor, round the motor's drive pulley, under the frog to the front of the machine, over the idler pulley, and back to the clamp on the front of the frog.

Thread the belt through the front clamp, get everything square, and pull the belt so there is no slack. It doesn't need to be taught.

Tighten the clamp.

Check the toothed drive pulley on the motor - it needs to be positioned so that the belt runs over the centre of the bearing. Slacken its set screw and move it if need be.

Cut off any spare belt with sidecutters - leave about 20mm free sticking out of the far side of the clamp.

Set the belt tension with the tensioning screw. The belt needs to be taught, but no so taught that it impedes the turning of the motor. Be gentle...

Check that the frog still moves freely front and back in the machine - there should be a certain resistance from the magnets in the motor, that is all.

Also check that the belt runs true. It should not tend to move from side to side more than 1mm or so. If it drifts (and especially if it rubs against edges and so becomes hard to move) then adjust the front bearing left or right to get the belt running square over that. You can move the motor left and right too, but it is often more effective to slacken its nuts and to tilt it very slightly relative to the threaded bars by not having the bars at the very bottom of the U-shaped slots in the motor's carrying frame. Then re-tighten the nuts.

Cut the off the excess belt - the remainder will be used to make the X axis. Leave 10mm or so sticking out of the clamps at either end.

Finally, attach the endstop microswitch to the h-shaped printed bracket with the M2.5 screws, washers and nuts. Attach the bracket to the frame at the back beside the motor:

Use the M3 screw, two washers, and nut to secure it. Before tightening these, make sure that the frog hits the button on the switch at the end of its travel.