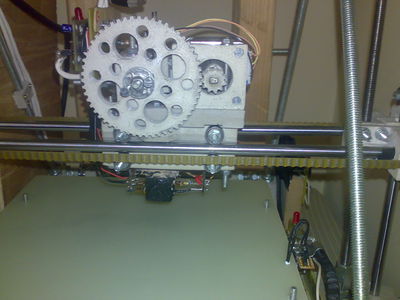

DIY Direct hot end

Release status: Experimental

| Description | Mostly DIY direct hot end variation

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Disclaimer and Introduction

At this point this is highly experimental, so use at your own risk. Also please edit, post on forum or pm opinions, findings, for the benefit of community - tyvm. Its not sure anything here will be an improvement over current design(s), or if it is any easier to DIY, this is the intention at least, but time should tell.

The older design has a small thread inside a ptfe, where it fits a brass barrel that has a hole alongside and inside it. Originally was using nichrome wire as heating element. I think now most ppls use heater blocks with heater resistors by attaching a heater block on the threaded barrel. There are 2 weak points in the use of this:

- the thread is very small number, thus has small teeths and doesnt grip the thermal barrier very good;

- attaching a heater block on the other end of the barrel makes it to act as a lever, as being subject to all the "giggling" of the reprap movements, inertia, moment forces etc (probably with original nichrome the solution was lighter and this had lower impact)

This variation tries screw the thermal barrier on the heater block, directly, without any middle pieces. Getting rid of the threaded barrel which can cause problems. There are several other designs that more or less, do that, in one way or another, with peek or metal body and ptfe sleeving, etc. This page has nothing original on it, maybe the gas nozzle (havent seen posts with that yet), although i am sure somebody somewhere is already using a gas nozzle just like that, but i just havent found myself any page mentioning that, although i have seen mig welding tips and similar.

Thermal barrier

Here this is assumed to be ptfe. Although some special sorts of peek might work too, especially with the barrel being gone and filament being fed directly into the pool on top of resistors. This has to be proven though. There are several sorts of both ptfe and peek, see here http://forums.reprap.org/read.php?1,79524,80492#msg-80492. There is nothing absolutely generally valid about advanced plastics and usually what matters most is the additive material, which usually is not mentioned. The following are some ideas:

-a ptfe that is ivory-sh color, has a good chance of being the sort that has extra mechanical resistance. Or if its the other similar type (rare), it should fail very soon.

-a peek that is black color, has a chance of being the sort that has improved less friction, also. Remember this is not confirmed to work, its mere theoretical.

The thermal barrier(s) in the picture are 16mm diameter and 7 cm long. I had to make them longer than the version with the threaded barrel, to gain the barrel length. So the heater can come out of the carriage - i was afraid that if heater block is too much inside the carriage it may overheat it. Longer barrel increases the thermal dilatation proportionally, at least in theory if the temperature its uniform. Although its not uniform, the dilatation may get to be significantly more than in the case of a small height piece. This may also relate to the way it is mechanically supported.

The thread on it can be M10, M12 or even higher if needed, the effect of differences in it should be extremely small - it just needs to fit to the thread in the block.

Heater block

Aluminium, brass or inox? Probably aluminium because its lighter. However, its more fragile than the others so its threads might get damaged after repeated abuse. Good thing both threads are on the inside. The thread on the outside of the ptfe in the picture is M10x1.5mm (standard) because that was the tooling and what i considered at the time of making, but M12 (standard x1.75mm) would of had more "meat" between its "teeths".

Nozzle

A minor change is to use another nozzle type. This nozzle is found in any kitchen that has a classic cooking machine using natural gas or LPG. Its exactly the nozzle from which the gas comes out to be burned. Has certain diameters depending if the gas is methane or propane, and also depending on the size of the burner plate. Lift up the top of the cooking machine and you will see it. Made from brass, threaded on the outside. From what i saw typically these nozzles are from 0.3mm up to 0.8mm (with alot of values in between) and with non-standard M6-7-8 thread pitches 1 step lower than the standard (at least that is what i found around) but no doubt the variation can be bigger than this:

M6x thread - standard pitch 0.80mm - nozzle gas pitch 0.6

M7x thread - standard pitch 1.25mm - nozzle gas pitch 1.0

M8x thread - standard pitch 1.25mm - nozzle gas pitch 1.0

These nozzles have a blunt ending (like some do in the picture). Without a lathe, i mounted the nozzle(s) in a chuck of a drill press and using a sharp tool i took few layers around the nozzle output to give it a small clearance to gave the nozzle a ... nose[1]. The brass is just a little harder, but at the same time its still much more machineable than aluminium is.

The nozzle gets screwed inside the heater block. That means, it can get unscrewed to fit another. I have successfully printed with this, and also changed the nozzle directly. It is easier if the heater is at a temperature like 100-150C and if the heater block can be held in place with a wrench and the nozzle can be unscrewed with another wrench. So, make sure when making the block that a wrench will fit properly to it. I also did it filled with hard rock abs inside (cooled at room temperature), and the thread torque was enough to break off the abs inside and get the nozzle free. I was having a brass block as in picture when doing this, i dont know if aluminium thread would be damaged or not by doing so, as there is quite some initial effort in breaking the nozzle free.

Mechanical Support (mounting)

The current carriage doesnt really offer many possibilities to fix this on it, so it needs either some improvisation, or carriage needs some redesigning.

Principle Best way to fit this would be to have the heater block in a fixed position and have the thermal barrier free to expand towards the pinch wheel direction. This way the nozzle will always be at the same point.

Support 1 The classic way. This was achieved by pressing the thermal barrier against the top plate of the carriage. Easy enough to do, but thermal expansion makes the nozzle to move towards the bed surface a little. In the original design it was a peek barrier pulling it back, and this way of fixing seems more appropriate to that situation and less fitted to this context.

Support 2 The thermal barrier versions that i made had 2 circular slots for groove type safety locks, one at the top and one at the bottom. I initially thought that the top one should come on top of mendel carriage plate, and prevent the hot end falling down, and the one closer to the nozzle can be used to push against a spring from the bottom of the plate. So that the entire hot end could slide vertically a little. Until it hits the pinch wheel that drives the filament. The spring can give it a little tension. And the overall assembly tends to stay down anyway - at least according to Newton. So there is nothing "against nature" about it. The downside of this approach is that the thermal dilatation will elongate the nose towards the heated bed, in the same direction as before.

Support 3 Two somewhat small u-shaped pieces of metal (or other means - dunno the english name, pls edit to correct this), could be used to tighten the thermal barrier directly, and these can be fixed with 2 nuts onto screws coming from top plate. Not a bad choice, and dilatation will push both ways according which side this assembly is closer to. If the plates contact with barrier is considerable, it might even help cool it at some extent.

Support 4 Having the heater block fixed and thermal barrier 100% free after the thread is also a variant. Heater block can have 2 screws passing through it (above resistors) and these screws being fixed onto the 2 screws already existing, at 90degree angle, with both top and bottom nuts and some plate insulator in between each sides. This way the heater block should be totally fixed (if vertial screws are insulated shouldnt heat up), and the thermal barrier would expand 100% towards the pich wheel, being vertically restrained only by heater block on the down side. At some extent a little constrained by the filament, and horizontal contrained by the hole it passes through.

Probably best would be support points 3 or 4, with 3 being the most "tangible" one and 4 being somewhat of a stretch and depending on what is there at hand. Remains to be seen.

Alternative miscelaneous materials

Yet other materials, possible replacements of the "typical" ones, to use with reprap for different purposes:

- RTV gasket silicone, its the silicone that can be found virtually at any gas station; it is used as a gasket fill between the engine block and top of the block with the valves. It stands ~350C or so, usually black or red color. I used it to cover the entire heater block. I dont really have a clue about what temperature exchange is between it and surrounding air, but i guess it cant be higher than with the bare metal exposed. I also used it to cover the underneath of heated bed, so less heat would go towards bottom. Here it also can be used to fix the thermocouple or the thermistor on heater block. It dries fairly fast and it its kinda more rigid than the typical sanitary silicone, and gets a fairly good grip on many materials. If it doesnt stick well sandpaper the surface it might help it adhere. Its cheap. Probably can be used in several other ways too. Silicone is generally given shape, before it "hardens" with the finger dipped in liquid soap, but a little saliva can do the trick aswell - e.g. keeping the silicone from sticking to the finger. I guess it depends how pervert one is ^^ - i use my saliva, but i will never disclose exactly what finger i use!

- Huge heating conduct gasket, the types used in steam heating conducts - street lines type. If you seen a big metal pipe that has like 20 big bolts around it, this is the stuff that comes in between: the old (classical) type at least, maybe now there are some other new materials who knows. Are gaskets like 20-50 cm diameter, and minimum 4-5 mm thick: usually made by a mix of graphite, azbestos and other insulating materials. Unlike advanced plastics, these are true termal insulators, especially older type ones. Usually have refractory properties up to 500C or 750C. A rectangle of this material can be put between the heater block and the heater block. Also this is fairly hard material. Cutted in a small strip, i used this as retainer on the thermal barrier. Sort of instead of peek. At approx 230C after quite some time, the other side of the material has around 70C. This material should also be available in plate shape, prior to be cutted round to fit the pipes. I had a very very old plate, dont really know where exactly to source it today, but must be some ways.

- High temperature vowen tubing, covered with silicone, the type that is generally used in electronics to cover wires exposed to heat. The silicone type is somewhat elastic. Tubing that can be cutted in length, and basically used as a bandage to cover the heater block or to insulate other things, with silicone on it. Its resistant and tough - imo way better than ceramic tape for this purpose. Strange enough, the silicone coating, once ignited, burns very well by itself (is this supposed to be fire resistant?), and when its done burning, remove the ashes and the woven material inside remains clear and can be used at much higher temperatures. I used the woven material soaked and filled with heat transfer compound to "dress up" the first resistors i had on the heater block, but after that i got bored and covered them in kapton as i started to believe that kapton probably has better heat transfer than previous situation. Kapton is easier and presumably better, but in the lack of, this can be a good variant also.

Considerations

Advantages

- thread on the outer perimeter of the thermal barrier can be made much bigger (M10-12-14) thus being much more robust than the variations that use a thread inside the ptfe;

- interchangeable nozzle(s) "on-the-fly";

- does not really need machined parts (except the thermal barrier that needs to be center drilled and threaded - preferably without changing the position - "in same catch")

Disadvantages

- increasing the temperature barrier height will increase the amount of dilatation and that might need to be dealt with;

- as a heater block made from brass is fairly heavy, and with all the "giggling" of a reprap, it might put additional stress on the thermal barrier and its thread; so prefer the use of aluminium for heater block;

- no definite way to support it; so it needs a little "creativity" with the materials at hand;

Effects to be determined

- dilatation effects around the thread:

a) if dilatation of the thermal barrier is bigger than the material used as heater, it will strengthen the joint, otherwise the opposite might be valid

b) suspicion: on the long term (if it gets there), the repeated thermal stress on the ptfe expansion might result it the blobbing on the outside near the ptfe exit from the thread, near the heater block, reducing the mass of ptfe inside the hole little by little and pulling it out (so maybe a small pressure applied the opposite way with a spring might counter-act this locally, or a diameter increase would help, or both)

- thermal barrier going inside the heater block: the melt zone changes, effect to be determined;

- remains to be determined if M10x1.5mm thread on the outside of ptfe is strong enough, or other thread types should be considered;