Moldmaking Tutorial

Contents

- 1 Soft Tooling for Casting

- 1.1 Overview

- 1.2 Before you start

- 1.3 Cores

- 1.4 Through holes

- 1.5 Layout

- 1.6 Walls

- 1.7 Tape sealing

- 1.8 Plasticine

- 1.9 Setup

- 1.10 Bumps

- 1.11 Pouring

- 1.12 Setting

- 1.13 Plasticine removal

- 1.14 Gates and risers

- 1.15 Pouring the next PDMS layer

- 1.16 Leave to set

- 1.17 Removing the cores

- 1.18 Inserting the cores

- 1.19 Ready to pour the resin

- 1.20 Resin setting

- 1.21 Finished cast

- 1.22 Compare with the original

- 1.23 Alternative - sloping the plasticine

- 1.24 A useful trick

- 1.25 Simpler shapes

- 1.26 Other materials

Soft Tooling for Casting

Overview

What you are going to do is to build a cavity, line the bottom with plasticine to form a split line, put components to be cast on that plasticine, and pour liquid silicone over them to fill the cavity and make half of a mould.

When the silicone is set solid, you will turn the whole thing over, peel off the plasticine from what is now the top, and pour in more silicone to solidify and form the other half of the mould.

You can then remove the original components by bending the silicone mould, put it back together, and pour other materials into it such as liquid resin to make copies of the original components.

With care this can be done with extreme accuracy and fidelity.

Before you start

You are going to need some liquid silicone rubber. The fancy name for this is PolyDiMethylSiloxane (PDMS). It comes in a variety of different forms (the most common being bathroom sealant). It is a thermoset polymer. The less cross-linking in the polymer, the softer it is. But for a mould there is a compromise: the softer it is, the easier it is to separate the casting from the mould, but the more prone it is to distortion.

Viscosity when the PDMS is liquid before it has set is another issue - if it's too viscous then bubbles in it will stay trapped and won't rise to the surface before it sets, giving a poor-quality mould. This means that the only way to use a viscous PDMS is to cast it in a vacuum to eliminate bubbles. Fortunately, there are now very inviscid ones available. The best one I've found is Viscolo 22 liquid silicone from Tomps.

You will also need something to mix the PDMS in (disposable coffee mugs from a vending machine are good), something to catch drips and spills (paper party plates are good), and sticks to mix with (sticks are good...). Electronic scales accurate to 1g will allow you to mix the PDMS in the right proportions easily.

Secondly you will need resin to cast in your mould when you have made it. The best resin I've found is polyurethane fast-cast, again from Tomps. This is as inviscid as milk when it is mixed, making it very easy to pour. And it sets in just half an hour.

You will also need an aerosol mould release spray.

Finally, confiscate Lego from the child in your immediate circle who has most recently annoyed you.

Cores

Any long thin holes in the object you are making will become long thin pieces of silicone in the mould. These will bend under gravity and so not make an accurate hole. Much better is to use cores. Cores are removable parts of a mould that you put in before you do the casting to make holes.

By far the majority of holes that you want will be cylinders. The easiest way to make cores for these is to use metal rods. Use silver steel - it is easy to cut and it is shiny (giving a smooth finish). Cut the cores longer that the holes they will make, and grind small flats on one end to make the core easier to grip and twist with pliers.

Through holes

Short fat holes don't need cores. Put tape over one end of each hole, and think about how the two halves of the mould will separate. You want the hole-shaped solid bit to come away with one half, and the mould the other side of the tape to be the other half. The tape is to allow easy separation - it splits the silicone in two. When you mould the object you may get a very thin sliver of resin where the tape went over the hole; this is easy to remove. This works for holes of any shape - not just cylinders.

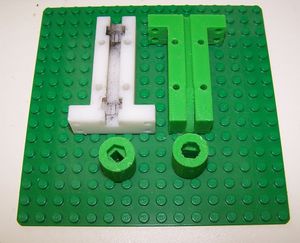

Layout

Position the objects you want to mould on a flat Lego base. You are going to build a wall round them. Make sure there is a good 5mm gap between everything and between each component and the walls. Allow more where the cores will come out, and make sure that one end of each core can touch one of the walls; the other end should be somewhere in the middle of the mould.

Walls

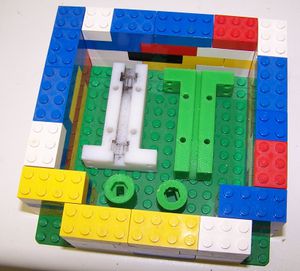

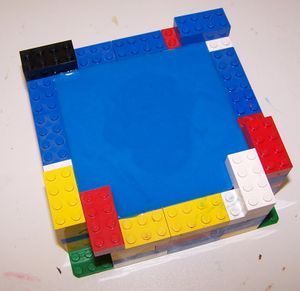

Build a wall round the parts. Make it two bricks higher than their height. You can bond the walls so that the cracks don't line up by offsetting the bricks to make the wall strong, but don't do this round the corners - you are going to have to remove and to replace each wall individually.

Incidentally: thanks to Ian Adkins for the Lego idea...

Tape sealing

Take off each wall and seal the cracks on the inside with tape. When you put them back, add tape down the vertical corners to seal those too. Don't bother to seal the join with the base.

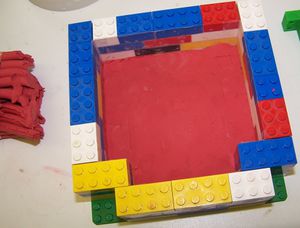

Plasticine

Push plasticine into the bottom of the cavity one brick deep. This will form the split line of the mould. If the plasticine is a bit stiff a few minutes on defrost in a microwave will free it up.

Make it flat where you can, but build it up into mounds if need be to accommodate the shapes of the components that you are going to make. See below for an example of this.

Alternatively, you can make the plasticine slope (see the next section and the bottom of this page).

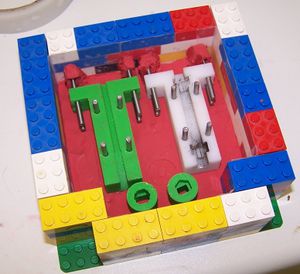

Setup

Place the components to be moulded on the plasticine base, pushing them down into it slightly to make a good seal. If the components have a fat and a thin end put all of them down in the same direction (note that I have done this here, but not above). You will tilt the mould slightly before it is filled with resin with the fat ends at the bottom - see the Gates and risers section below for more details. As mentioned above, an alternative to tilting the mould is to slope the plasticine within it; in some circumstances this may be simpler.

Put lumps of plasticine round the ends of the cores where they touch one of the walls. This will give an indentation round the end of the core, allowing it to be grasped with long-nosed pliers.

Push any vertical cores right down into the plasticine as far as they will go.

Bumps

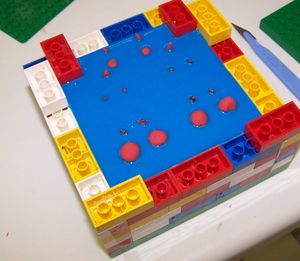

Make indentations into the rest of the plasticine surface with any object with a conical or spherical end. These will form bumps on one half of the mould and corresponding dents on the other half. These halves will then locate perfectly on each other, constrained by the dents and bumps.

Lightly spray the inside with mould release agent.

Pouring

Work out the volume of the mould above the plasticine. Unless the components being cast are very big, don't subtract their volume from that - that will give you a little extra material to play with.

The density of the silicone is about 1g per ml (i.e. much the same as water). Weigh out the appropriate proportions of the two components and mix them very thoroughly. Be particularly careful to mix in any material in the corners of the mixing vessel.

Then slowly pour the silicone in. Pour it in one place in the middle and let it flow everywhere else under gravity.

Setting

Fill the cavity right to the top. Place extra bricks across the corners to locate the walls precisely.

Leave it to set completely.

Plasticine removal

Take away all the Lego. Then remove the plasticine. Bits that stick can usually be got off by rubbing them with another piece of plasticine.

Using a scalpel carefully remove any slivers of PDMS that have flowed over the tops of the components.

Gates and risers

Put the Lego walls back. Adding extra Lego underneath may help to get them aligned.

The top layer of PDMS needs holes in to pour the resin through, and smaller holes for the air to come out. Put inverted cones of plasticine at the fat ends of the components; these will form the gate holes down which the resin will be poured. Put thin cylinders at the extremes of the thin ends; these will allow the air out as the moulds fill.

Remember that the mould will be tilted so that the thin ends are at the top of the slope. Imagine the mould filling with liquid resin and imagine that resin creeping up the slope under the top of the mould that forms the tops of the components. The point of the slope is for no bubbles to form here and for all the air to come out of the risers, which should be at the highest point. If there is more than one high point on any one component, put risers on each one.

Once more lightly spray the inside with mould release agent.

Pouring the next PDMS layer

Work out the volume of the top section, mix up more PDMS, and pour it in.

Leave to set

Again, leave the PDMS to set completely.

Removing the cores

Take away all the Lego and remove all the cores and any plasticine on their ends. The top layer of PDMS will be stuck to the bottom layer, but once you get a bit peeled away the rest should follow easily. Keep a scalpel to hand to cut recalcitrant bits, but be careful not to damage the mould in places where it actually forms the components.

Inserting the cores

Remove the gates and risers, and the components, then put the cores back in. Lightly smear the cores with silicone grease first - they are going to have to be un-stuck from the resin when it is set.

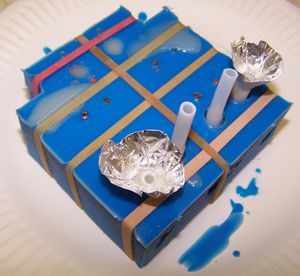

Ready to pour the resin

Put the mould back together, holding it with elastic bands. Don't make these too tight or they will distort the mould; better to use lots under low tension than a few under high tension.

Put the mould on a slightly-sloping inclined plane with the gates at the bottom and the risers at the top.

Cut some plastic tube (drinking straws work well), tape kitchen foil to it to form crude funnels, and place it in the gates. When the resin is poured these will give a small head, forcing it up the mould against the slope.

Resin setting

Weigh the components. They have a density about the same as the resin, so this tells you how much resin to mix (go 10% over to make sure you don't run out).

Pour the resin into all the gates in turn slowly. If you do this too quickly then bubbles won't have time to escape and you'll end up with holes in the objects you make. But remember that this resin sets pretty fast...

Pour the resin until it just starts to come out of the risers.

Finished cast

After half an hour the resin should be set well enough to take the mould apart and to remove the cast components. Once again, start by removing all the cores. Twisting them before pulling them will release any that are stuck.

The resin should still be just soft enough to cut the risers and gates off with a scalpel easily. The components are not fully hardened at this stage - leave them for a day before using them.

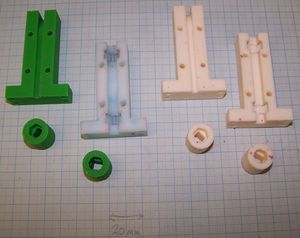

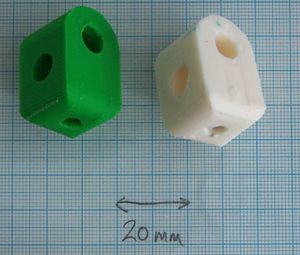

Compare with the original

Here are the original parts and their moulded equivalents. There are one or two slight inclusions of plasticine and PDMS in them, which would not have been there if I had been more scrupulous and careful. Mea culpa....

Alternative - sloping the plasticine

As mentioned above, an alternative to inclining the mould when you pour into it is to slope the plasticine within it. This is neater, but it uses more plasticine and more silicone. But if you do this you don't need to add straws to the gates when you pour in the resin.

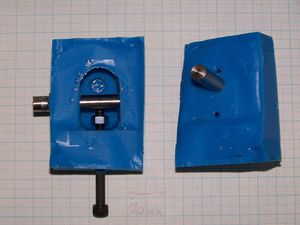

A useful trick

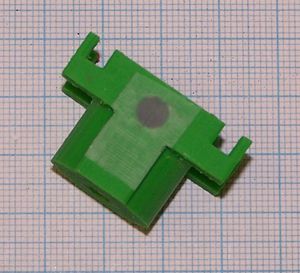

It is easy to trap a nut inside a moulded part so that you subsequently have a strong threaded hole into which to put a screw. On the left is a master component and on the right is a moulded copy with a nut embedded in the resin such that a screw can be put into it to form a clamp.

Here is the mould. As you can see there are two large cores, one of which will house a rod that is to be locked tight with a screw.

When the mould is made just put the screw in the appropriate hole (use a longer one with the same thread so that it sticks well into the region where the silicone will be). When the silicone is set, unscrew the screw to remove it from the mould, like removing a core. Then when you come to make the cast put the screw back with a nut on it. Grease the thread, but keep the rest of the body of the nut clean so the resin will stick to that.

The result will be that the nut will be trapped in the resin and you will then be able to screw a screw into it and generate a considerable force. This is much stronger than just using the screw itself to cast a thread in the resin.

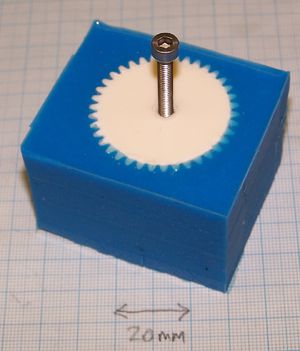

Simpler shapes

If you want to make something that has a large flat face the quality of which is not too important, you can make an open-cast mould. Mount the part in a Lego box as before, with the flat face you want level with the top row of bricks. Use a couple of thick hoops of plasticine attached to that flat face to suspend the part (in the case of this one they were stuck to the screw). Pour in the silicone being very careful to make it just come to the lip of the object you're making. Adjust the object on its plasticine to get it's top face flat with the level of the silicone.

To cast the part, simply pour resin into the open mould, again taking care to bring the resin just to the level of the top.

This shows a gear with an embedded nut and thread in its centre that was made by casting silicone round a commercial plastic gear with a screw through its centre. The screw was then re-inserted in the mould with a nut on it, which has become embedded in the middle of the gear giving a strong metal thread.

Other materials

You can also cast metal, as long as you use the right metal. Here is Wood's metal being cast; it melts about 70oC. The trick is to heat the mould along with the metal, then pour, then let both cool together. There is a similar (and non-toxic) alloy called Field's metal.

As you can see, it makes threads good enough to use, though the metal will not go into sharp corners (because of very high surface tension).

Here are some other materials that I haven't tried, but which may give interesting and useful results:

- Casting/Pewter

- Electrically conductive resin

- Very high temperature silicone (480oC).

- Thermosteel.

- Rose's metal

-- Main.AdrianBowyer - 30 Sep 2007