Delta

Release status: unknown

| Description | Delta type parallel kinematic manipulator setup to be used as repstrap

|

| License | |

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Delta is the name of one of many types of delta robot 3D printers. For others, look under Category:Delta.

Contents

Introduction

The Clavel- or Delta-robot is mostly known for its use in pick-and-place work in PCB fabrication and generic packaging applications. It features fast and accurate positioning and is relatively easy to build. We, User:Energetic and User:Reinoud teamed up to create a both easy to fabricate and light on the budget RepPrep/RepRap. Our goal is to be well under the current prices for Mendel and/or Darwin RepRap's.

We decided to design and develop the bot through a series of prototypes, learning and refining on each iteration.

Prototype 1

The initial prototype designed and lasered by User:Energetic. It was cut out of 1 cm acrylic sheets by a shop. It proofed the concept of the magnetic ball bearings and the overall structure of the design. Regretfully it was never driven by an Arduino/Sanguino other than simple stepping.

Prototype 2

Lessons were learned from prototype 1. It proved to be hard to reproduce the machine since non-standard 4mm shaft NEMA 17 motors were used and needed some intricate drilling in the side of the sheets to receive the bolts and nuts. Since acrylic also turned out to be quite expensive, we decided to go for plywood. We replaced the 10 mm acrylic with a set of three sheets of plywood with the respectively thickness of 3, 4, 3 mm so to easily accommodate the 4mm nuts and bolts.

The structure was also modified to accept larger upper-arm ranges to give it a larger work-space. As 4mm shaft steppers are hard to find, the design was modified to use the standard 5mm shaft of NEMA 17 steppers.

Although we've learned a lot of this prototype to justify a prototype 3, we'll first try to get it to work first. We might stumble on other unforeseen challenges!

Calibrating

The bot can detect the arms being in the start position. However, due to various causes the exact start angles of the three arms are not known but a rough estimation. Start angles being wrong result in a severe warped space that is far from flat nor the right size. The prototype therefore needs to be calibrated at least once in its life or when its reassembled. The calibration scheme is fully automatic with a single micro switch.

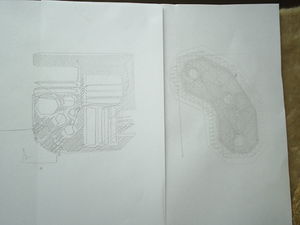

First drawings made

After a long wait, the bot is starting to make drawings with a pencil. Regretfully the pencil wasn't as stiffly mounted as we would hoped for so the quality of the drawing is not that well due to the hysteresis. No art yet, but some s3g files of the calibration object and a scaled up version of one of the Mendel pieces.

Prototype 3

Will most likely not feature the timing belts and pulleys. They proved to be too hard to get and can hopefully be replaced by either higher resolution microstepping or by a lasercut gear system. It will most likely also not feature the current ball-bearings used to hold up the cut-out wheels since the ball-bearing, but also the bolts attaching them also turned out to be hard to get.

The plan is to make this one either the next prototype, or the final, of the laser-cut Delta Reprap.

Prototype 4

Well.. speculation here... First RepRap-able version? Perhaps an upside down GUS Simpson? But then I might as well go make a regular one instead..

Firmware

Reinoud

User:Reinoud has written a ReplicatorG compatible firmware that does both the needed coordinate transformation and the real-time control. The goal is to have the complete bot, including the extruder, running on either a single Arduino or on a single Sanguino with standard Polulu stepper controllers and standard NEMA 17 steppers. As for SDD card recording and playback support, a Sanguino might be required since the imported implementation of the FAT/MSDOS FS alone takes about the half of the Arduino 32Kb flash program space and currently just doesn't fit with the rest.

Is http://deltafimware.googlecode.com/svn/trunk/ the lastest version of that firmware? NO it isn't ... the current firmware is not yet released since it contains some serious flaws that we'd like to fix first.

That's great, I'll just run off and write my own firmware from scratch >:( just release it as is.

dc42

The dc42 fork of the RepRap Firmware includes support for delta printers. See Configuring and calibrating a delta printer using the dc42 fork of RepRapFirmware.

Firmware Math

TBD

Mailing list

Arm proportions

Some people seem to think that a good (according to what measure?) set of arm proportions (using the notation from the Mzavatsky paper) is:

- given some base size f

- actuator size e should be about 3/5 of f

- upper arm rf should be about equal to actuator size e

- lower arm re should be about re = (rf + (f-e)/2) = (rf + f/5)

- Given the tiny angle dT that the upper arm moves per step, the positioning error in the build volume is about (3/2) dT rf (???)

... fill in details[1] ...

Existing Designs

"Mjcbruin" from the Netherlands designed the this delta bot for $70. It is driven by 3 hobby servos, and is controlled by an Arduino. The code has been published at the letsmakerobots link. Video Design + code

User:Reinoud has built a similar design with servos.

- Ugly Stewart Platform ( http://builders.reprap.org/2006/09/ugly-stewart-platform.html ) : crude prototype for hydraulic Stewart platform.

- first stab at a Stewart platform RepRap: http://blog.reprap.org/2006/02/reprap.html

- Biollante: a few more stabs towards making a hydraulic Stewart platform RepRap: http://burningsmell.org/biollante/

- Biollante posts: http://builders.reprap.org/search?q=Biollante

- Volksrobot: http://sites.google.com/site/volksrobot/

- "Baby sized reprap" http://forums.reprap.org/read.php?1,15252

- "Delta robot kinematics" by mzavatsky goes into excruciating detail on the math, has some nice illustrations, and ends with some sample code in C and a Lego implementation.

- http://forums.trossenrobotics.com/tutorials/introduction-129/delta-robot-kinematics-3276/ - Mathematics discussion and C code example for inverse kinematics

- P.J. Zsombor-Murray. "An Improved Approach to the Kinematics of Clavel's DELTA Robot". 2009. Includes both delta inverse kinematics and closed-form delta direct kinematics.

- Tripod positioners such as the SpoonPod, the Helium Frog Delta Robot, and Viktor's tripod repstrap demonstrator have many similarities to Delta positioners, as does the TRap.

- Forrest Higgs prints nice herringbone racks and pinions on his RepRap, and speculates that perhaps they will be useful in a Delta or Stewart RepRap.[2][3]

- Let's make robots! : Delta bot[4] made from hobby servos

- [5] The EMC documentation claims it can handle hexapods and other non-trivial kinematics ...

- Yazzo PolyBot - Cranberry Edition by WilliamAAdams "Delta Bot: Equilateral Awesome"

Files

Tooling

Lasercutter and standard tools are sufficient to make the current repstrap version.

- What's the minimum required working area (=minimum part size) needed? -- Nichtich 15:29, 4 March 2012 (UTC)