CoreXY

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

The CoreXY arrangement and the very similar H-bot arrangements are popular mechanical arrangement for a RepRap motion stage.

The CoreXY and the H-bot are a Cartesian arrangements -- they makes it easy to move the head in straight lines along axis 90 degrees from the other axis.

There is a change in the belt pattern from the H-bot arrangement to the CoreXY arrangement. The belt loads on the carriage of an H-Bot tends to rotate it around Z axis. So the positioning accuracy rely only on the stiffness of the carriages. H-bot shall be very solidly built for good accuracy. CoreXY mechanism add two pulleys to equilibrate loads and so the carriage stays always perpendicular without relying on the stiffness of the sliding mechanism. In fact, the CoreXY mechanism is the same as what was used for decades in cable based auto-parallel drawing tables. CoreXY have longer belts than H-Bot but they allow lighter construction. [1][2] The advantage of coreXY are discussed by some:[3]

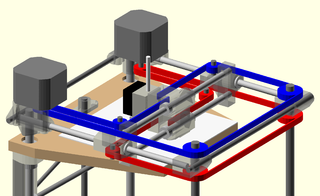

There is two ways to built the CoreXY belt system.

- Both belts are on same plane so belts are crossing and they tend to rub one against the other at crossing point. Twisting the belt on the crossing path limits the rubbing. A small finger can be installed to separate the belts at crossing point.

- The two belts could be set on two different levels (see image). This creates a small tilting momentum on the hotend carriage and increase the momentum on shafts if pulleys are installed on cantilevered shafts. This also save some space on the return pulley side as the pulleys could be stacked.

Firmware option are identical for CoreXY and H-Bot.

A CoreXY and a H-bot are a parallel manipulator system. In other words, the motors on a CoreXY system or H-bot system are stationary.

Parallel manipulator systems, such as CoreXY and h-bot and Dualwire-Gantry (DW-G), typically have much lower inertia than serial stackup arrangements. The lower inertia of a parallel manipulator system, when using the same motors and the same forces, typically gives more rapid acceleration than serial stackup arrangements. (For example, the Prusa i3, RepRapPro Mendel, etc. use a serial stackup -- in other words, some of their motors are pushed around by other motors).

To maintain the low inertia, they are generally equipped with 'Bowden' tube hot-end.

In DIY world, the D-Bot, derivative of the C-bot, A V-wheel based design, had some success and is probably the most frequently self-built CoreXY. The more recent hypercube design[4] based upon tubes also drafted interest, needing less printed parts than a C or D-Bot. An HyperCube built with very light carbon tubes have low mobile mass allowing good performance.

Some Chinese manufacturers are confusing people while presenting H-Bot printers as CoreXY (Creality Ender-4 is presented as being a CoreXY while it is an H-Bot with associated problems)[5].

Machines in standard aluminium profiles

| Name | Last update | Description | Movement XY | Movement Z | Useful volume | Size | Speed (print/travel) | Link | |

|---|---|---|---|---|---|---|---|---|---|

| Vulcanus (different sizes) | may 2015 | Frame in aluminium profiles, with metal and printed parts | bearings on rods | 4 rods and two trapezoidal screws (2 motors) | 200 x 200 X 260 (up to 520 x 520 x 1500) | 440 x 440 x 600 | 300 (print? travel?) | http://www.instructables.com/id/Vulcanus-V1-3D-Printer/ http://www.thingiverse.com/thing:821066 http://www.instructables.com/id/Vulcanus-MAX-CoreXY-Aluminum-Frame-RepRap-3D-Print/ | |

| VSlot-CoreXY | february 2015 | Modification and update of project AluXY by zelogik/jand while using Openbuild profiles. Good documentation. | V-slot with wheels (said to be more silent) | with 2 rods 12mm and trapezoidal screw 10mm thread 2 | 210x195x240 | 400x400x500 | ? / ? | https://github.com/sdavi/VSlot-CoreXY | |

| C-bot | january 2015 | Profiles Openbuilds and printed parts | with V-slot with wheels, non crossing belts | with V-slot, transmissions with 2 trapezoidal screws (2 motors) | 250x250x? | 500x400x400 | ? / ? | http://www.openbuilds.com/builds/c-bot.1146/ | |

| RepRap-XY by "jand" | january 2015 | Machine like the AluXY by Zelogic, but with printed parts. Detailed BOM with complementary information | ? / ? | https://github.com/jand1122/RepRap-XY | |||||

| AluXY by "Zelogik" | march 2014 | Aluminium frame with parts in aluminium | rods 8mm with Igus bearings, crossed belts | With two rods and trapezoidal screw | 228x236x217 | 350x350x300 | 200 / 350 | http://forums.reprap.org/read.php?397,297740 https://github.com/zelogik/AluXY | |

| forkLIFT MK1 | 10/2018 | 3030 extrusion aluminum frame, 2020 bed frame, all motors out of the chamber. Belt tensioner at the motors to the back. F623ZZ bearings. Tool changer ready. All rods and bearings removable without disturbing belts. | Pair of 8mm rods for X with 3xLM8UU bearings for X. Pair of 12mm rods with 2x LM12LUU for Y. Parallel belts no twist. Belts aliment assured by self aligned parts. | 4x 12mm rods with 8x LM12UU bearings and two leadscrews for 300+ beds and half for up to 220mm beds. Fully integrated carriage and motor/rods/nut holders for easier alignment. | 300x300x300 standard version. | 480x470x500+ | Up to 100m/s and 300mm/s. Maybe more with better tuning. | https://www.thingiverse.com/thing:3072219 | |

| Voron V2.4 | 13/5/2020 | 2020 extrusion aluminum frame, 2020 bed frame. Fixed build plate. ABS printed parts. Detailed BOM, step by step manual. Print it Forward for 3d printed parts and Part Sourcing Guide on Discord group. Over 120 built so far. | 1 MGN9H rail for X, 2 MGN9H rails for Y. Stacked parallel 6mm GT2 belts. | Cast aluminum MIC6 build plate to minimize warping. Z is controlled by moving XY gantry in Z direction, 4 independent motors auto align gantry to build plate to eliminate need for mesh leveling. | 250mm to 350mm cubed standard versions. | 460x460x480mm for 300mm cubed version, fully enclosed | Up to 120mm/s (print) and 300mm/s (travel), up to 6000mm/s^2 acceleration. | http://vorondesign.com/voron2.4 https://www.reddit.com/r/voroncorexy https://discordapp.com/invite/wfwFKuf | |

| Jubilee V2.1.0 | 8/2020 | 2020 extrusion aluminum frame, 2020 bed frame. PLA printed parts (except PETG motor plates). Detailed BOM and assembly instructions. Capable of automatic tool-changing with 409mm rack space for idle tools | 1 MGN12C rail for X, 2 MGN12H rails for Y. Stacked parallel flush 6mm GT2 belts. | Moving Z Bed plate. Bed is MIC6 and kinematically coupled to the frame enabling automatic bed tramming. | 300mm cubed. | 455x605x553mm, enclosable | Up to 130+mm/s (print) with a Volcano nozzle and 500mm/s (travel) with Moons' Motors. | https://github.com/machineagency/jubilee https://github.com/machineagency/jubilee/wiki https://discord.gg/XkphRqb |

References

External links

- CoreXY theory

- Kevin Craig. So, you want to build an H-bot?.

- OpenBuilds: H-bot

- Google groups: H-bot and CoreXY 3d printers.

- So You Want To Build An H-BOT?.

- RepRap forum: H-bot type Reprap?.

- RepRap forum: H-bot with Fishing line concept.

- RepRap forum: HBot using fishing line (actually uses the CoreXY configuration)

- "Concept: h.ORD" is a "CoreXZ" 3d printer.

- CoreXZ discussion: "RepRap forum: Vertical H-bot with x and z axis?"

- "Tantillus sized h-bot"

- Dice: Tiny coreXY in aluminium structure