MM PLD - v0

Contents

Multi Material Pulsed Laser Deposition

Vacuum Chamber

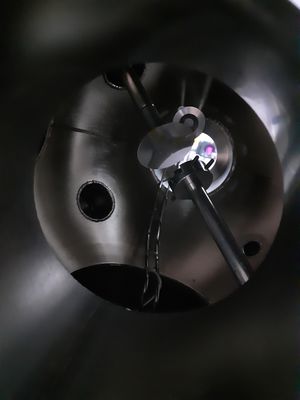

So when I began working with the deposition system, it had a quite standard configuration. Most of the design choices were already made, and I only had to design and fabricate the in-chamber mechanical components. The system had a MDC spherical vacuum chamber with plenty CF flanges emerging radially at different angles. The target and substrate were diametrically opposed, as can be seen in the following picture.

It held a 25mm target rotating at about 20 rpm at a distance which could be adjusted between 50 and 70 mm by a translation/rotation manipulator located in the substrate flange.

The system used a QCM to monitor the thickness of the films.

Laser and Optics

Ablation was achieved by means of a frequency doubled Nd-YAG laser (Continuum) which was capable of producing 30 ns pulses of about 300mJ total energy, with a repetition rate of up to 10Hz. The beam was filtered by an dichroic mirror, and steered by other mirror towards a lens which focused the light onto the target.