User:Npm5073/Blog

Main | About Me | Class Blog

For this class we write weekly blogs on a variety of topics that have to do with 3D printing.

Contents

- 1 Blog 1: Thingiverse

- 2 Blog 2: Open Source Blueprints for Civilation

- 3 Blog 3: 3D Printed Prosthetics

- 4 Blog 4: A continued discussion on Blog 2 based on others input

- 5 Blog 5: RepRap timeline

- 6 Blog 6: What are our next steps?

- 7 Blog 7: The possibility of printing research equipment

- 8 Blog 8: What is all this intellectual property stuff?

- 9 Blog 9: Filament: The good, the bad, and the ugly

- 10 Blog 10: Hot Ends

- 11 Blog 11: Show and Tells we have seen

- 12 Blog 12: A review of the REPRAP Timeline

- 13 Blog 13: Printing Research Equipment

- 14 Blog 14: Intellectual Property

- 15 Blog 15: Show and Tells we have seen

Blog 1: Thingiverse

We had to explore around on Thingiverse and find different items.

An item that is amazing/beautiful

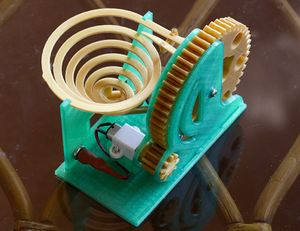

Here is a marble machine that is powered by a small electric motor. I find this marble machine pretty amazing because of its creativity. I don't think it does anything particularly useful, but it is a good example of a fun projected that can be created with a 3D printer. Source

An item that is funny or strange

Seeing a printed version of the Mac OSX trash bin made me laugh. This is one of many designs I found that have little practical uses, but are incredibly intricate. I suppose it would make an interesting paper weight though. This was also a top contender for the next category: An item that is useless. Source

An item that is useless

Here is a miniature Nintendo (notice the size of it compared to the penny). No matter how cool a super tiny Nintendo looks I can't think of it could be used for. I also find it interesting that it is made out of 8 different parts. Again I'm impressed by the complexity of things that seem useless to me. Source

An item that is useful

Here is an earbud case designed for easy storage of earbuds. This is one of many items that I wanted to print immediately after I saw it. This earbud case makes me excited about additive manufacturing because it gives people the opportunity to create products to meet their needs. Source

An item that surprised me

I never would have thought about making a gum machine out of printed parts. This is something that gets me thinking about how many industries 3D printing will impact in the future. It also makes me want some bubble gum. Source

Blog 2: Open Source Blueprints for Civilation

A) The Open Source Ecology project was created to design and build the machines that will benefit society by sharing and building off of their respective ideas. I like the idea of the OSE project because their designs are meant to be inexpensive to build compared to buying a new, similar machine. During his TED talk, Marcin talks about the financial difficulties he experienced as a small scale farmer. I live on a small farm in Lancaster, PA owned first by my grandfather and now my uncle. I have seen the financial struggles firsthand. The newest and greatest equipment is too expensive for these small farmers to afford, so they need to buy used equipment. My uncle uses two tractors that were made in the mid 1950's and they constantly need to be repaired.

The start-up costs alone were enough to discourage me from a farming career at a young age. But the OSE project gives me hope that small farms will once again become profitable. I love that you can build the tools that you need and make changes to them when necessary. In this video, Marcin talks about building tools that can replicate themselves (he even gives a shout-out to REP RAP). He mentions that he wants to design a set of machines that are necessary to start a civilization. I do not think that we need to reinvent the wheel with all of Marcin's ideas, but I do see his point with regard to products that are designed to break after a certain time or overpriced equipment. I am excited to see where this project goes in the next few years. I hope that more and more people contribute to the project so machine design will continue to improve. Hopefully someday soon it won't be uncommon to see someone plowing a field with a tractor they built.

For more information on OSE see: TED Talk Open Source Ecology Wiki

B) The New Yorker magazine recently wrote an article about the OSE project called THE CIVILIZATION KIT. They talked a lot about Marcin's philosophy about OSE and the living conditions at his farm. He is very set on the idea of living in a civilization that is self-sufficient. I think this article is a little tough on Marcin. He is trying to build machines using as many simple processes as he can while working in the early stages of a brand new civilization. I'm not sure that he necessarily needs to work in those conditions though. I believe that the OSE project would be more efficient if they used modern techniques to make the initial machines. As long as the drawings and prototypes are made, OSE has accomplished their goal.

The New Yorker article also points out the poor living conditions mentioned by some of the volunteers at the OSE farm. I cannot imagine why not having running water or electricity would further OSE's mission of creating open source machines that are needed to create a civilization, but I respect that Marcin is using a majority of the money donated to the OSE project to build machines and further OSE's mission. I also do not find it surprising that OSE has some critical flaws. They are a nonprofit organization that is trying to build everything itself. So I would expect their facilities to be outdated and the working conditions to be less than ideal. It also makes sense that many of their volunteers were unqualified and left after a short time because of the living conditions and hard work required. I think that Marcin has some good ideas that will benefit society, but the execution of these ideas will be delayed because of the work environment the OSE team is subjected to.

Marcin wrote a short response to the New Yorker (found here). He clarifies OSE's goals to be solving pressing world issues, where the New Yorker article claimed that it was to start self-sufficient communities. He also claims that they are "not letting idealism prevent us from achieving our goals." I call BS on that one. If you do not have electricity in your facilities because you want to make it yourself, then I would say that you are letting idealism prevent you from achieving your goals. In the rest of the response, Marcin discusses how it is hard to run a nonprofit organization and why there are always going to be trade offs between comfort and progress. I agree with most of this defense because I would not want to be in his shoes and I do not think I would know a way to make OSE more efficient (other than more modern facilities). Overall, I think Marcin will struggle for the duration of the project to find qualified people who are as dedicated to the project as he is. If he can do that, I would be interested to see how it works out. But there is no way you will ever see me working for him (not that he would even want my help).

C) One professor I think would be interested in a PSU OSE club would be Leland Engel. When I took his ME 340 class, he was very focused on creativity and a design process that was very iterative. He is also an advisor for the FSAE car and a few other similar projects at Penn State. I am not sure what his opinion is on open source technology, but I think the engineering that would go on would entice him enough to hear us out.

Blog 3: 3D Printed Prosthetics

Who created this design and when/where was it done?

Mason Wilde used a 3D printer to print a prosthetic hand for a family friend. The designs Wilde used were created by Ivan Own and Richard Van As. The two designed the hand because Van As lost a finger in a wood working accident. The two made their first prototype in November of 2012 and had a 3D printer version by January of 2013.

How would one make one of these prosthetic hands? This design using a 3D printer can be found, free of charge, at www.thingiverse.com. The 3D printer might be harder to find, but any local college with an engineering department is probably a good place to start looking for one. There are also some tools needed to assemble the parts and the cost of the printing material.

For more information about this project or other similar ones see the following links.

Other News articles about this story 1 2 3

Other News article talking about this Design

4

5

6

7

8

9

10

11

Other 3D printed Prosthetic Hands:

12

13

Background story of the Robohand

Blog 4: A continued discussion on Blog 2 based on others input

Many of my classmates had good thoughts on the OSE project that I overlooked in my second blog post. Many of them had similar ideas about the challenges of these machines being made by everyday individuals or especially people in third world countries. Jess makes a good point when she says "I think that when it comes to building machinery, the average person would not consider them to be DIY, easy to fabricate projects. Even as a fairly intelligent person, myself, that is about to graduate with a degree in Mechanical Engineering, a project like this would likely take me a long time with the help of several people." Kevin goes one step further by talking about the issues that can come up when something breaks or isn't working properly. He said not having troubleshooting tips could cripple the development of the machines. Dongao seems to agree with this statement and has a good thought about the safety of building your own tractor. I know I would not want to drive a tractor that I built just due to the safety concerns. Zach also points at that these plans will be hard to spread to places in the world without access to computers and the internet.

Even with all the skeptics our there some people were willing to look past the issues with the project and see its benefits. Tom sees Marcin's true idea for the project is "not to provide instructions for the best machines that can possibly be made, but rather to provide complete instructions for pretty good machines". Anthony agrees with me about the benefits of having cheaper equipment when he said "In today’s world so much emphasis in product design is put into aesthetics even though it doesn’t affect the performance of the machine. Having a more affordable machine that gets the job done without all the bells and whistles can be just as beneficial to society". Eric finds himself wishing he lived in a simpler time without competing economic goals ruling the day. I too thing that a simpler life would be more enjoyable and I think we share that idea with Marcin, but I doubt either of us would go as far as Marcin to live that dream.

In all the blogs I read, Nam was the only person who ever mentioned that he would consider building any of these machine. If Marcin's project is going to be successful, educated people like Nam need to build Marcin's designs and add to them.

One thing that stuck out to me in the responses to the New Yorker article about OSE was that most people thought the Emily Eakin was unfairly critical of the project. One interesting thing I saw in Sam's blog is when he said that "She is unable to write an article for the common man because she isn't connected in any way with what I look at as the common man; Her husband is a professor at the Prestigious Brown University, she writes for the New Yorker. Come on". I agree that she probably has a different understanding of what the "common man" looks like than I do (being born and raised in Amish country and all). I think Ben is still speechless about this subject because of the deep sadness he feels when reading Eakin's critiques on OSE.

Blog 5: RepRap timeline

3D printers have progressed very quickly over the past few years. Our classes Media TImeline shows many of the many noteworthy articles about 3D printers in the news. Some projects get a lot more media attention than others. 3D printed guns were well represented in the timeline which is most likely due to the political issues that it creates. Over time the general tone of the articles in the timeline has stayed the same. However they started talking about how amazing it is that 3D printers exist to amazement at how much they can do.

There are many article that discuss important 3D printing technology. One technology that is important in the progression of 3D printers is the capability to print with different materials. One that stuck out to me was an article about printing with Titanium using Direct Metal Laser Sintering (DMLS). Printing with different materials can expand the uses of 3D printed parts.

Some people seem to have gotten caught up in the idea of printing food. In my opinion printing food is just a novelty. Here is an article about printing chocolate. I can't see a purpose for this other than it is really cool, but with a $4600 price tag is a little much for something cool.

One post I saw that was interesting was one that discussed how moon dirt can be used as a printing material. The article in BBC talks about a team at Washington State University that used simulated moon rocks to print small objects. This is something that is obviously not possible for our class to test, but the idea of using natural materials is something that seems cool and like something that the OSE project would love.

Blog 6: What are our next steps?

I think there are many logical "next steps" for our class to pursue. Personally I have spent a lot of time dealing with extruder problems for the purple printer, so I would love to try to redesign the extruder system we are currently using (or at least try someone else's design). I think there are many ways we can improve our current printers by iterating the designs we are currently using. I would also like to see improved extruder tips (I know we save a ton of money making them the way we do, but I think there is room for improvement without sacrificing cost).

I also think printing a robot arm would be cool. We print a lot of 3D printer parts, but what about printing parts to make other robotics. Here is a link to a 3D printed robot arm. This may be something we could convert into another 3D printer design as well. I think this is the perfect place to test our crazy ideas because we can create the parts for them cheaply and because they might work.

Another type of 3D printer I would love to try to build is a delta robot 3D printer. I think the design looks intriguing to build and would be cool to try. The drawback on this design looks like the extra hardware it requires. But hopefully we can try to build one.

Blog 7: The possibility of printing research equipment

To me the most attractive thing about 3D printers is the ability to cheaply make things you need. The idea of printing research equipment is the perfect example of a way to do that. The fact that Dr. Pearce could make his equipment for 1/20th of the price of purchasing one makes a 3D printer worth the investment in any research setting. Our class has used 3D printers to assist research in similar projects. One current project some members of the class are working on now is designing a jig to hold replacement glass tubes perpendicular to the surface of a micro force transducer while they are glued in place. You can purchase a jig that will do this for around $300, but we think we can make one that works just as well for a fraction of the price. This isn't exactly the same thing as Joshua suggests, but it is making necessary equipment for research equipment at a fraction of the price.

A team in Beijing has developed an AFM nanoscope out of legos and arduio boards. Normally an AFM nano scope costs around $100,000, but the lego version costs around $500 to build. I think its awesome that this team was able to do it, and the fact that they used lego and 3D printed parts makes this seem like something we could do, if they would make their designs open source (which after a quick search does not seem to be the case). One thing I am discouraged about is the fact that they haven't made the project open source. The article says, "The student teams involved in the event will now return to their universities with the goal of continuing their AFM developments and improving the nanoscale resolution of their designs." I understand that these are PHD students who need to do research on, but it is frustrating to know that this is possible to make an affordable AFM and not know how to do it. It is clear that I am not the only person who feels that way because the first comment on the article says, "Don’t call the article “how to build a low-cost AFM…” unless there are actually instructions on how to build said AFM". I like the fact that this is possible to build, but I have no desire to re-do work that this team has done just to get to the same point they are. The beauty of the colorimeter project is anyone can build one because the plans are online. Someone who has never used a colorimeter before can build one very cheaply and make further improvements to the design. The issue with the AFM project is I have no idea how one works, and I don't think I'll ever do enough research to be able to make one myself, but I bet I could build one if they put the plans and code online. And by building one I would be learning how an AFM nanoscope works and possibly find ways to make the current design better. I don't think I will be building a colorimeter or an AFM anytime soon, but I would like to build a 3D printer, but only because there are good instructions online showing me how. Thank you open source technology.

Blog 8: What is all this intellectual property stuff?

Intellectual property is an important way to ensure that people, or more often corporations, are able to receive compensation from their creations. Copyright and patents give the creator of either a work or a design of a product or process the right to use their creation for a limited time. Trademarks are a sign, design or expression which differentiates a product form another. Copyrights, patents and trademarks are different from trade secrets because they are publicly disclosed, where trade secrets are not generally known. All of these have the purpose of allowing a creator to profit off of their creation.

John Hornick wrote an interesting commentary about the issues with intellectual property and 3D printing. He summarized what he believes 3D printers do to IP in 5 I's which are listed below:

Infringement: when anyone can 3D print things with virtually any functionality, the risk of IP infringement away from control will become increasingly high.

Identification: infringement away from control will be increasingly difficult to identify.

Impractical or Impossible: it will be increasingly impractical or impossible to enforce IP against infringement away from control.

Irrelevant: IP will become increasingly irrelevant.

I agree with much of what Hornick says about IP becoming irrelevant as 3D printer technology progresses. He also claims that the idea of patents and copyright was to encourage innovation, but now it looks like it actually restricts innovation. I think thats true just by looking at all the delta printer modifications on thingiverse. The only drawback I see to this is that most people are trying to build the best 3D printer they can with a very limited budget, where companies could spend huge amounts of money making their designs. But having said that I don't think there is a huge quality difference between a well-made rewrap and a similar priced 3D printer (if that even exists).

My biggest worry about working as engineering is that I will be forced to stop contributing to open source projects. I'm not sure if this is realistic or not, but it wouldn't surprise me if that was in the fine print of the documentations I sign when I start working. I think this would be especially true if I worked in any of the places that the article mentioned. I'm sure Boeing wouldn't be happy if I had a thiniverse profile that is full of printable quadcopter parts.

Blog 9: Filament: The good, the bad, and the ugly

1) Findig good reviews for filament is not an easy task because of how many suppliers there are. The rewrap wiki has supplier reviews, but most suppliers don't have any reviews and the ones that do only have a few. Based on those reviews here are a few suppliers who make good quality filament:

Bad:

Amazon.com also sells PLA from many different suppliers. I will probably buy all of my PLA from amazon because of their abundant reviews, decent prices, good customer service and free 2 day shipping for amazon prime members. How can you go wrong?

2) As far as dual extrusion materials go, thread.com has good information about PVA. PVA is water-soluble and is printed at similar temperatures to PLA. It also does not require a heated bed.

Good reviews on different suppliers of PVA filament are difficult to find. The Reprapwiki page for PVA is almost empty, so it doesn't seem to be widely used. Amazon sells PVA from a few different suppliers, but there are no reviews for any of them. And at around $80/kg its not a cheap thing to just try one out.

3) My next PLA purchase will probably come from amazon (again free 2 day shipping is awesome). I will most likely make a last second decision on what supplier to buy from based on current reviews. At this point my bigger question is whether to use 3.0 or 1.75 mm filament.

Blog 10: Hot Ends

There are many different varieties of hot ends one can buy or make. Our class uses home made hot ends adapted from a Techzone kit. Our tips are good because they heat up very quickly, they do not require a fan to cool the tip, and they can get hot enough to print other materials (but we need to get rid of the insert to print at much higher temperatures). The issues with the tips we make is how difficult they are to wire. The thermocouple can easily short on the body of the hot net, the nichrome wire is difficult to wrap, and that stove sealer stuff is a pain to deal with.

Some other types of hot ends are J-head and E3d. Here is a good blog about the development of J-Head hot ends. As you can see there are many different variations. J-Heads are generally reasonably priced middle of the road hot ends. They take a long time to heat up and they can't heat to very high temperatures because the PTFE tubing used inside the hot ends.

An alternative to the J-head is the E3D tip. Someone said that the J-Head is the Ford of hot ends while the E3D is the cadillac. The E3D is an all metal tip that can heat to over 300 degrees C. It won't heat up as fast as the tips that we make though. I bought an E3D for the printer that I am building. Hopefully it is worth the price.

Blog 11: Show and Tells we have seen

Some of you have satisfied the Show & Tell requirement already. Please talk about something you learned or thought was really interesting in a presentation which one of your peers has done.

Jared's show and tell about services that let you control your printer remotely was really awesome last week. I could tell he knew a lot about the subject and he had actually signed up for one of the sites. He also showed us a few websites where you can have stl files printed and sent to you. He has purchased things from one of the companies before and said they were good quality. I wish he would have mentioned that before I bought parts for my personal printer from ebay.

I thought the coolest show and tell was the one Zach did about the air hockey table that uses 3D printer technology to make a really good air hockey opponent. It just shows that 3D printer technology can be used to do pretty sweet stuff (even if it isn't super practical). The funny part about the air hockey table is the better tuned you get the system, the more you will lose.

Sam also made a good powerpoint about different bio 3D printing technologies. They do some pretty cool things that are way out of my understanding, like printing bone and cells. Its amazing to think that we have a team that is working on similar projects.

Overall I have been impressed with the Show and Tells we have seen so far. Our class clearly is excited about the future of 3D printing technology.

Blog 12: A review of the REPRAP Timeline

Jess:

Ben:

Zack:

Drew:

Tony:

Chai:

Blog 13: Printing Research Equipment

Jess:

Ben:

Zack:

Lee:

Hao:

Blog 14: Intellectual Property

Jess:

Ben:

Zack:

Sam:

Kyle:

Eric:

Blog 15: Show and Tells we have seen

Jess:

Ben:

Zack:

Nam:

Eva: