User:DanielStein

Contents

Introduction

In my Freshman year of college at Drexel University I almost built and modified a 3d Printer kit for Freshman design, however I got talked out of it. So that summer i decided to take the plunge and design, source, and machine everything for my own 3d Printer. Here is what I have accomplished so far. Special Thanks to Diken Machine Inc. for teaching me how to machine, letting me use their machines and helping with the cost of metal.

Current State

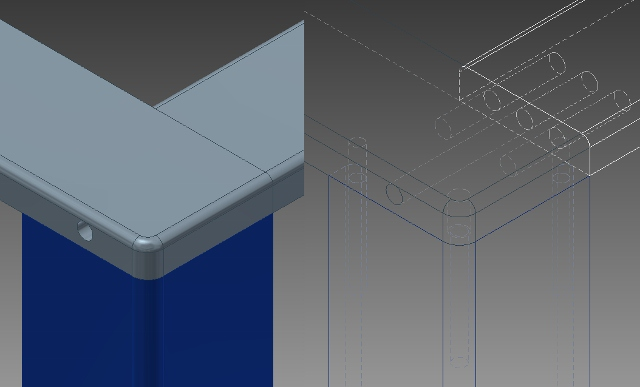

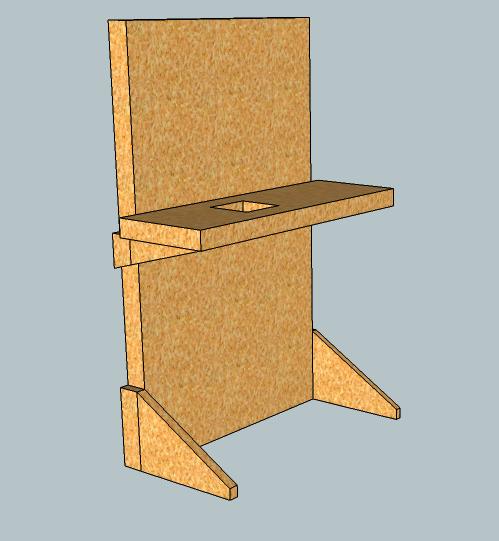

Frame

After much deliberation about what kind of frame to use to build a 3d printer i came up with my own. I choose to use aluminum angle and rectangle bar to minimize cost, pieces, and fasteners needed. I looked into many different types of frames from 80/20 to kits that contain hundreds of pieces for the base. A good foundation is key to any type of precision machine. The frame of this machine is innovative because it requires only basic machining to make the 12 frame members and the fasteners are 16 1/4-20 bolts and 32 dowel pins.

Electronics

When i first started on this project i had little knowledge of electronics and went with what was popular which was ramps 1.4, however soon after later into the summer Rambo came out so i decided to use Rambo being the latest and greatest. At this point in time i would consider Smoothieboard being that it has a 32bit microprocessor as well as a modified ramps 1.4 on an Arduino Due board.

Firmware

Marlin

Extruder

Hot end

J Head

Cold end

Wades Geared Extruder

Interface Software

Printrun

Slicing Software

Slic3r