User:Crosby Owens

Contents

Contact Info

Thingiverse Account

http://www.thingiverse.com/dbpc/overview

Intro

Hi, My name is Crosby. This is my user page where I will post my weekly blog posts and projects that I am working on in. I will continue to update this page as I progress through the class.

Projects

Working on updating

Blogs

Blog #1

A) Something amazing/beautiful

I felt that a lot of the designs posted on thingiverse did not have very many beautiful designs. Most of them seemed very blocky or crude. I really liked this lamp because of its abstract flowing lines. I also liked it because it seemed like something that would actually be harder to make by hand than using a 3d printer.

http://www.thingiverse.com/thing:19104

B) Something funny or strange

I found this rabbit holding a gem to be particularly strange for a couple of reasons. One reason that it looked really strange to me is the rabbits face. It has a kind of evil possessed look to it which is pretty weird. I also found it strange because the rabbit was holding a black gem. This lead me to believe that the gem it is holding is possessing it.

http://www.thingiverse.com/thing:135905

C) Something useless

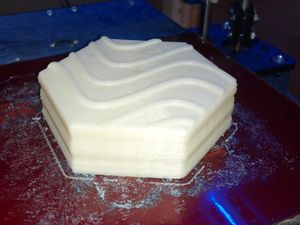

To me anything that is made out of plastic to look like food is a complete waste. All it does is make me hungry. This fake zebra cake doesn't even look that realistic. The only possible use I could see it having is to be used in a prank but even that would not be very good. Therefore I feel that it is completely useless and a waste of plastic.

http://www.thingiverse.com/thing:115387

D) Something useful

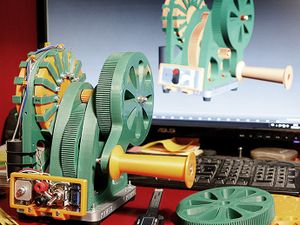

I thought this generator was really useful because it allows you to use the 3d printer to make electricity. This seemed really cool to me because you could potentially use something like this to power the Raspberry Pi or even the printer itself. It could also be used to power other things too. The only downside is that it isn't made from al 3d printed parts (wires and electrical stuff.

http://www.thingiverse.com/thing:145186

E) The ‘best’ printable Raspberry Pi case you can find

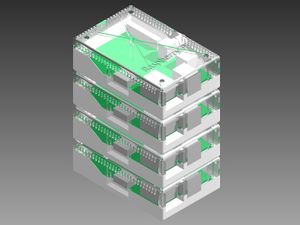

This Raspberry Pi case stood out to me because of its stackable design. I thought that would be very useful in a class like ours with multiple Raspberry Pi's because it would allow them to be neat and organized which would save us space. The design also didn't seem too complicated and looked relatively easy to print which is key for making any Raspberry Pi case good.

http://www.thingiverse.com/thing:19978

Blog #2

Write about a topic (or two, or three) which interests you which we've discussed so far - or not discussed in detail yet. It could be your project, or a particular type of 3D printer, or something you think would be cool for us to explore in the future.

One topic that we have discussed in class that I find really interesting is using 3d scanners and printers to print detailed versions of objects. I believe that the future of 3d printing will be with using 3d scanners. I also find it amazing how the scanners can take real life objects and turn them into models on a computer. As printers start to get better scanners will allow us to print complex shapes that couldn't be rendered using CAD. These better quality models could be really useful for in the health care industrial for creating prosthetic limbs or dental fillings. This could also be really useful for people historians trying to recreate old objects. 3d scanners working with 3d printers also bring up a lot of interesting copyright issues. If someone scans something they buy in a store and print it is that copyright infringement?

A different type of 3d printing that we have not discussed in detail yet is three dimensional printing of food. As of right now it seems that the 3d printing of food is still in the under a lot of development and is not in wide spread use yet. But considering how fast 3d printing has taken off and that NASA is funding research on 3d printed food, it wouldn't be surprising to see it become a reality in the near future. The benefits from 3d printing of food would also be huge. For one creating food using an additive process could greatly decrease food cost and food waste. If the technology becomes cheap enough it could even help solve world hunger. 3D printed food would also be much quicker to prepare (if already printed) since the only preparation of the food left is cooking if any. Overall 3d printing food is one of the more interesting 3d printing topic that we haven't really touched on in class.

Blog #3

Read some of your classmates blogs (you should be able to find them on the link above). I want you to look for the best post or two you can find, and link to it. Explain why you chose it, and what makes it good in your opinion. If there is anything you can think of to improve it, comment on that.

One of my favorite blogs from blog post 1 would be Dimitar's I thought his chart layout for that post was a really cool idea. I also thought the octocat that he found was awesome. One slight improvement he could do to make it even more awesome would be to turn the chart vertical and make one column description and the other one column pictures. This is more of a personal preference but I wanted to mention it.

One other blog post that I found to be really interesting was Justin's Blog post 2 about variable geometry hot tips. I liked this idea and thought it was really cool. It does sound very complicated to make but it doesn't sound impossible to design. This idea really stood out to me because it was something cool that I didn't know existed. This topic is so new that when I googled "variable geometry hot tips" I couldn't even find anything about it.

I also thought that Brandon's blog post number two was very interesting. His post focuses on the economics of 3d printing. He brought up some interesting points that I had not really thought about. The one suggestion I have for him to make his post better would be to fix the link for the video.

Blog #4

Watch this: https://www.youtube.com/watch?v=2j84BDoNkt8

Comment on each project, and their mode of operation (give it away for free). How does this compare with traditional business models? Can you point to any companies using a similar business model? How does this sort of thing strike you?

The first project that is discussed in the video is the arduino project. The arduino is a micro controller that has an open source hardware and software design. The purpose of the arduino project was to teach people who are not familiar with electronics about electronics by making the arduino cheap and the software easy to use. Since the design of the board is open source they do not care if you modify it and sell it as long as they are credited.

The other project mentioned in the clip is RepRap. The idea behind RepRap is making 3d printers that can make themselves. The design for the rep rap printer is put online and is open source so that anybody could make changes or improvements to design. This allows the RepRap design to be evolve with input from thousands of designers. It also allows the number of rep rap printers to grow continuously like an ecosystem.

Very few companies have a similar business model to these companies. One company that I can think of that is similar is Wikipedia. Wikipedia is also non profit and gets most of its money to host the the website from donations. All of its pages can also be edited by anybody just like the designs for RepRap parts. Wikipedia in nonprofit and its purpose is to create a free encyclopedia for everyone to use. This is very similar to how Arduino and RepRap operate. One other company that follow a simillar model is craigslist.

I think all of the projects and companies like this are really cool because they help a lot of people learn and gain knowledge which is awesome. I think that the number of companies like this will continue to grow. Also as 3d printing technology gets cheaper and better we may see more and more companies like this start in the future because it allow physical objects to be shared almost like data.

Blog #5

Read this:http://betabeat.com/2011/04/3d-printing-hits-a-strange-milestone-shape-pirates-and-copyright-claims/ This event happened a few years ago, but was one of the first 3D printing related IP 'events'. It illustrates what happens when the DMCA is applied to STL files on thingiverse. This event is discussed in some detail here: http://www.publicknowledge.org/Copyright-3DPrinting This is not a short document, but it gives a strong analysis of IP and 3D printing. A) Re-examine the objects you found on thingiverse in your first blog. Assess each one for copyrightable or patentable elements.B) Look over the things which your fellow students found. Are any of them particularly obvious cases of copyrighted or patented material which have been found by your classmates? C) Discuss both reasons why you might be interested in the “licensing of non-copyrightable files”. D) Bonus: Why might you consider the author of the first article to be naive?

A.)

Cellular Lamp:

This lamp dosent really have any copyrightable elements since it was created using the generator on this website. It dosent have any pantentable elements since it more of sculpture than a useful object.

Rabbit Holding Gem:

This object might actually be copyrightable since it appears to be an original design created by the uploader. Since it is not useful and is just art it doesn't really contain any patentable elements.

Zebra Cake:

I don't feel that the zebra cake has any patentable or copyright elements because it is just a copy of a piece of food. No real use and it isn't really a unique design

Hand Power Generator:

This hand powered generator might have some patentable elements. If it is a completely new design that was made specifically because of its ease to be 3d printed than it might be patentable. It probably could not actually be patented since its design was released to the public on thingiverse. This object doesn't contain any copyrightable element since it is a useful non-artistic object.

Raspberry Pi Case:

There might be some patentable elements of this raspberry pi case. If the uploader of this case was the first one to create a stackable case for raspberry pi's it might be patentable. But like the hand powered generator, it probably could not actually be patented since its design was released to the public on thingiverse and there are a lot of designs for other cases already out there.

B.)

One possibly copyrighted item I found is in Dimitri's blog post 1 here. It's the model of a smart car. Car designs are normally copyrighted by their manufactures so this is probably a copyrighted design. One other possibly copyrighted design I found was in Madeline's blog post 1 here.. It is the model of mickey mouse. I pretty sure that mickey mouse is copyrighted design.

C.)

The legal side of licensing of non-copyrightable files is cool because it a convenient way for it to be clear about the uses of the design. I also think that the cultural reasons for licensing of non-copyrightable files is also interesting because it can be used to show the creator wants the design to evolve like the arduino or reprap designs.

D.)

The author of the first article could be viewed as somewhat naive because he made it seem like the design was copyrightable when in fact as mentioned in the second article it is a optical allusion which is not copyrightable and it is a copy of a work created a long time ago which also makes it not copyrightable.

Blog #6

"Blog 6 is in some sense an extension of blog 5. I want you to go through your classmates responses to blog 5 regarding IP and the penrose triangle model. Your blog should consist of any points which you missed on your own, but which you realized in the process of reading your classmate's work. Try to summarize the most important points as taken both from your own readings and the contributions of your classmates."

After reading the blog posts of some of my classmates I found some points that I missed and some interesting opinions.

One interesting point was brought up by Ian about how patents dont always work the same in every country. I had forgotten about this and it made me think about how it would be really cool if there was an international patent organization of sorts.

I also found out that I missed a couple of my classmates copyrightable items. Ryan pointed out that Quinn's my little pony and yoda head are both copyrightable.

Matt also brings up that STL files are lossely portected by copyright which is pretty interesting.

Alot of my classmates also brought up how the author of the article could be considered naive because he does not mention that the penrose triangle was first produced by someone else.

One last point I found That I didn't bring up is that licensing non-copyrightable things is a good way to protect your design from future changes in copyright law.

In summary I feel that most important ideas in the two articles is that not everybody knows the laws behind copyright and patents, and this can sometimes lead to confusion. I also came away with a lot of knowledge about how patents and copyrights vary from each other.

Blog #7

Choose any article which we have not discussed in class or previously posted to the media timeline (http://reprap.org/wiki/RUG/Pennsylvania/State_College/RepRap_Media_Timeline) Please discuss the article both in terms of the hope (how will this change EVERYTHING), and hype (how is this the same overhyped stuff we already know about). Try to find the middle ground and take away the important elements of the story.

This is the article I chose to write about.

Hope:

Skin frame printing technology could be the next big step in plastic 3d printing. The skin frame algorithm works by creating an inner skeleton for the part and a skin that goes over it. This is awesome because it can use up to 70% less filament than using standard printing. What makes skin frame printing even more amazing is that the object still maintains a lot of the strength of the original object. The reason that using less material is awesome for 3d printing is because the cost for most 3d printed parts are per volume of filament. So if the cost of 3d printed parts went down by 70% it would open up the technology to many more people who weren't considering it before. This technology could be the next big breakthrough in 3d printing.

Hype:

Even though this technology looks promising I am still doubtful about how big of an impact it could really make in the 3d printing world. One problem that I see with skin frame structure is that it requires a pretty precise and accurate 3d printer for it to work effectively. I feel that if you tried to print one of those structures with a reprap style printer it wouldn't be nearly as strong and may not even hold together at all. Another problem that I see is that they do not mention any plan on how they are going to release the algorithm for this structure design. If it is released as expensive software then it may never get fully utilized by the majority of DIY 3d printers. Even though the claim that this design makes strong prints they also mention that the parts have "sufficient flexibility and variability", which to me sounds like weak parts that aren't very useful. Overall I am well skin frame printing will work.

Blog #8

Part A) Check out the first 4 projects from the AMRI and describe them. Do any stand out to you as particularly valuable? Can you think of any similar projects we might propose here? Part B)In addition to Open Source, Design, Learning, Education, Research, Additive Manufacturing, and Fabrication, can you think of any other adjectives which might be used to describe what we've been doing more broadly in addition to what is being done in the class and elsewhere? The more unique examples you list, the more XP you will earn for this. Part C)Can you think of any memorable word which might be used to house the descriptors from part A? My example: OSPREY: Open Source Platform for Research, Education, and You-name-it Not great, but that's the sort of thing we are looking for. Silly is okay, as long as it is accurate or descriptive.

A. Projects 1. Open SLS This is a project to create an selective laser sintering machine using a lot of open source printed parts. It also describes how to make the materials to do laser sintering.

2.Ink-Jet printing Bacteria The second project was about using an inkjet nozzle to print bacteria. They planned to do this by using a reprap style printer and replacing the extruder with the inkjet nozzle.

3.Digital light projection of photolithography plastics. This blog talks about how Digital light projection can be used to 3d print plastics. What is really cool is that it shows how everything is created upside down. It also addresses the challenges of keeping the printed part stuck to to the platform.

4.CellStrueder This project is creating a 3d printed syringe extruder that can extrude material at a microliter level. The goal of this project is to be able to print cells to study biological pattern formation.

One of the coolest projects that I think we could possibly do something similar here would be the DLP printing of plastics project. I also thought the selective laser sintering project was cool but I wasn't sure if it would be safe for us to mess around with lasers.

B.) Some other adjectives I could think of are: -low-cost -creative -innovative -engineering -DIY

C.) One acronym I thought of is CLAMOR Creative Low-cost Additive Manufacturing Opportunities for Research Another one is STEAMS STudents Engineering Additive Manufacturing Systems.

Blog #9

"Discuss this: http://blog.3dhubs.com/post/65508330490/maker-tales-how-to-3d-print-your-own-coffee-grinder What is good about this? Anything negative? Can you think of other things which might be made using these design principles?"

This design for a build and print your own coffee maker is pretty cool. One thing that I like about it is that it seems very simple and easy to use. TI also design looks very easy to take apart and put back together. The idea to use old parts for a one off project is cool but in a design for other people it might not be that helpful. Sure a lot of people have glass jars laying around but how many of them are actually the identical. I would also find it annoying that if the motor went out in my coffee grinder and I wanted to fix it that I would have to wait until my vacuum breaks to get a new motor instead of just ordering a part. Something else that could be made using a similar design to this one could possibly be a small desk fan or a food processor.

"See This as well: http://blog.openstructures.net/pages/os-waterboiler-by-jesse-howard Describe the differences between making 1, 10, 100, and 1000 of these objects (scroll down) Is this over-elaborated by Jesse? Can you state what is described in these images as a design/manufacturing principle?"

The first problem that I see with this design is that the hot water runs through what appears to be an exposed copper pipe. This could be a safety concern since it would be easy to touch it by accident if it was on the counter. It also looks like the pipe is positioned way too high off of the table for most uses and when using a normal cup it could be pretty easy to miss and spill hot water all of the table or your hand. There are a couple differences in making this design as a single unit compared to the design for larger quantities. One changed that he makes is that the large quantity designs rely less on used parts than the single unit design which results in the unit price for ten being larger than the single. The larger quantity designs also use more bulk purchased items to reduce cost. One problem that I see with creating 1000 of these machines is that the time to print all of the 3D printed parts would be immense without a large quantity of printers. Due to the price of this water boiler even if it was sold as a kit by a company it would be too expensive. Its hard to see the picture clearly but assuming you print all of the 3d printed parts yourself and using the 1000 prices as an estimate the material cost will still be over $20 which means it probably wouldn't sell in a store or online for less than 40 and thats just the cost for half of an unassembled water heater. I don't really see the advantage of spending hours printing and assembling parts to make this water heater when you can go on amazon and get this better and safer waterheater for less than half the price and have it arrive at your house in two days with no work.

Blog #10

"Do some research into Jeffrey R. Immelt and Terry Guo. Who are they? What have they each said about 3D Printing? Can you come up with any rationale for why they might have the opinions which they express?"

Jeffrey R. Immelt is the CEO at general electric and is also on the President’s Council on Jobs and Competitiveness. Mr.Immelt has stated that he feels 3D printing will be the future of the manufacturing industry. GE the company he works for uses some 3d printed parts in their new jet engines. I think that Mr.Immelt has the rational that he has because we works in an industry where the manufacturing of complex parts are very critical and he sees that additive manufacturing could be very useful at his company. I also think as an American company he sees 3d printing as a way to cheaply manufacture products in the United States.

Terry Gou is the founder and ceo of the chinese company Foxconn. Mr.Guo has a very different outlook on the future of 3d printing. He feels that 3d printing does not have any commercial value for mass production. Mr. Gou is also quoted with saying, "3D printing is a gimmick. If it really is that good, then I'll write my surname 'Gou' backwards". I believe that Gou's opinion varies greatly from Immelt's opinion because of the different backgrounds of the company they work for. Foxconn makes primarily electronics circuit boards and processors which is an industry that does not seem to be as affected by 3d printing. Also Foxconn relies a lot on cheap labour to make its products whereas 3d printing has higher start up costs and less labour. The other big difference I see between GE and Foxconn that could explain his opinion is that Foxconn mass produces its products on a lot larger scale than GE which would make 3D printing seem less effective for their company.

Blog #11

"Now that you've had some experience working with the printers, what are the things which have frustrated you the most or occupied the majority of your attention? Mechanical problems? Software? Wiring? Construction? Describe some issues you have encountered and what you did to solve them. On that note, also describe any problems which you failed to solve or gave up on, or are still working on. What's wrong, and how else might we try to fix it?"

Mechanical and construction problems seem to occupy my time the most. Partly because they take more physical time to fix than most electrical problems. One construction issue that I worked on and fixed was the play in the purple printers bed which made it hard to level. I fixed it by pulling the bearings tighter to the rod with a zip tie. I also had to tighten a lot of the nuts and bolts around the purple printers chassis which I think made it print a little more accurately. Most recently I changed the z axis clamps on the purple printer from the old rubber to the new clear rubber to prevent it from sliding off.

Overall the one printer that is the most irritating to me is the black printer. I have only worked on it for a couple of classes but it always seems to have something new wrong with it and the x axis never seems to be fixable. I cant figure out what is causing the x to not work properly it seems to be a electronic issue now but I am not completely sure.

Blog #12

"Please look over these links: http://blog.cubehero.com/2013/11/19/know-only-10-things-to-be-dangerous-in-openscad/ http://blog.cubehero.com/2013/11/11/how-to-generate-extruded-3d-model-from-images-in-openscad/ For those of you who use Solidworks, OpenScad is an entirely different method of doing similar types of work. If you know your desired dimensions, you can easily describe many objects in terms of code.This allows you perform what is called 'Parametric Design', where changing key starting parameters allows the creation of a wide range of forms far more quickly than drawing each type of form individually. In fact, you can create a spectrum of infinite designs in this way. What are the strengths of a platform like OpenScad? What are the weaknesses and limitations? Would you ever be tempted to use it, or the process of turning images into models shown above? If so, for what?"

There are a couple of key advantage that I see to using OpenScad over a traditional CAD sources. One key advantage that I see is that it is free to everyone since it is open source. It also looks like it would be a much "lighter" program than Solidworks or Inventor which would allow you to run it on older slower computers or possibly a Raspberry Pi. I also like how simple it was to create basic shapes all it requires is one line of code with dimensions and its done. One other big advantage for OpenScad that was stated in the article is that since it created shapes based on "constructive geometry" it is a lot less likely for the program to have holes and will be easier to slice and print.

I also see a couple of disadvantages to using OpenScad for certain projects over Solidworks and Inventor. The first thing I noticed i the article when he was making the chess piece is how many steps it took. It would be much quicker to make the entire body of the chess piece in solid works with just one revolution and then on a sketch plane cutting out a rectangle for the extra little part. One other downside is that the parts that you make in Solidworks look more professional and can be rendered in high resolution or easily be made into a multi view sketch.

I could actually be tempted to use it for modeling if the part was something that I was printing for myself and it was relatively simple. Like a doorstop or other items that are comprised of geometric shapes. If the part is more complicated or is a design that I would want to show off to other people I will prbly stick to AutoDesk and Solidworks.

Blog #13

"Peep this: http://www.youtube.com/watch?v=dfNByi-rrO4 Why would we want to incorporate this into our printing? What capabilities would this give us. If we could print conductive pathways into objects, what would you try to make with it? How might we try to make it work with the printers we use?"

We would want to incorporate this into our printing because it is awesome! The ability to print conductive material could be really useful to test out electronics circuits. It could also get other departments like electrical engineering interested in 3d printing. Obviously we could try to print basic circuits with this but we could also try to print objects with hidden circuits. We could print some sort of object that if you touch two spots it could light up or something cool like that. I think the easiest way to make it work would be to use something like this cell extruder we discussed earlier on. If the syringe had a fine enough tip this could be an easy way to print conductive pathways.

Blog #14

"While the OHM printers we've been building and using are robust, I'd like to find cheaper options we might build en-masse. I found one, which I'd like feedback on. Check out the images/video: http://reprap.org/wiki/Smartrap_mini http://www.thingiverse.com/thing:177256 You all have some degree of experience operating and tuning our printers. This is basically a printable version of the printrbot, one of which you may have noticed sitting in class. What sorts of strengths and weaknesses do you predict/project, as compared to the systems we currently build?"

Blog #15

"There are a number of somewhat crappy '15 things..." lists related to 3D printing like this one: http://www.businessnewsdaily.com/4743-odd-things-3d-printing.html Is there anything in there which you've not been exposed to during this course. Point out anything which seems new to you. From my perspective, this sort of list misses the more practical solutions which people can create when they have their own 3D printer. For example: http://imgur.com/a/T17it Mounting brackets for game consoles seems like a small thing, but think about all of the other plastic components and custom parts you encounter in furnishing a home. Are there opportunities here for entrepreneurship? How so?"