User:Crg5149/Blog

Contents

- 1 Blog 1: Thingiverse

- 2 Blog 2: Marcin Jakubowski's Open Source Ecology Project

- 3 Blog 3: Kanas City Teen Makes 3D Printed Prosthetic

- 4 Blog 4: Reviewing Classmates' Responses to Marcin's OSE Project

- 5 Blog 5: Examining the SCRUG Members' RepRap Media Timeline

- 6 Blog 6: Projects that would be a logical next step...

- 7 Blog 7: 3-D Printed Lab Equipment & LEGO Atomic Force Microscope

- 8 Blog 8: Intellectual Property and 3D Printing

- 9 Blog 9: Filament Reviews and Support Material

Blog 1: Thingiverse

We had to explore around on thingiverse and find different items.

Something that is amazing

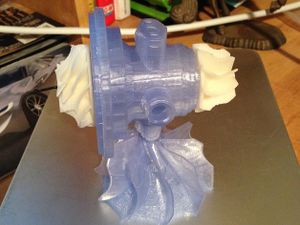

This is something I think is amazing, and could be very useful for an engineering demonstration if a prototype turbo was in the design process. I have a turbo that I modeled in SolidWorks and was not sure if the 3D printers would have the ability to print all the parts for it, but clearly they are fully capable of doing so.

Something that is funny

I think this is pretty funny because I follow a website called "TheChive" which has a lot of t-shirts, novelties etc. for Bill Murray. I always thought Bill Murray was really funny, especially in Caddyshack and wouldn't ya know it...somebody already has a 3D printer ready keychain!

Something that is useless

Besides being somewhat funny, this ring is absolutely useless in my opinion. It's going to get caught on everything, and be in the way. Just don't.

An item that is useful

I like making paracord bracelets, but it's not always easy to find plastic buckles that curve to the shape of a person's wrist, so with 3D printing one could choose customizable radiuses for a specific person or just make one anytime the buckles break. In my case, my roommate's dog destroyed mine!

Something which surprised me

This definitely surprised me as I was browsing through Thingiverse. I thought it was a pretty cool idea though if you want to stand out in a crowd at night!

Blog 2: Marcin Jakubowski's Open Source Ecology Project

Question A: I want your general impressions of the OSE project; positive, negative, utopian, etc. Please do a bit more research than just viewing the video, as it is now several years old and they have made some progress since then. Links to more recent videos and media will earn you a better blog.

Response to Question A: After watching the short video presentation by Marc Jakubowski on the OSE project my first impressions were both positive and negative. My first positive impressions came about when Marc admitted to being useless with his hands, in the sense that he could not build or create any physical piece of equipment. I often find that many people who live in their minds, and can prove mathematical theories, derivations etc. do not place any value on those others who are just the opposite. Those opposites are people who have a tough time grasping difficult concepts in their mind, but can build just about anything with their hands, and get practical work done. So, it was nice to see somebody as brilliant as Marc admit that those hands-on skills are extremely valuable, and take the time to learn and understand them to the best of his ability. I personally believe that developing both aspects is extremely important, and produces some of the best engineers.

It also left a positive impact on me that he was not only willing to humble himself by learning those hands on skills, but then took the time to create open source blue prints with instructions on how to build essential equipment for a self-sustaining society. Most people who come up with good ideas just want to cash in right away, sell out and leave the project they started behind them. However, I think Marc truly has a good heart and means well with his intentions to help developing/underdeveloped countries create a self-sustainable society with what seems to have an ultimate goal of ending starvation.

The one negative thought that was running through my mind while the video was quickly highlighting some of Marc’s equipment, specifically his tractor, was that his lack of experience in the field may lead him to believe that he has designed an adequate piece of machinery, but in reality it is anything but that. Just because it has four wheels with chains providing decent traction and a motor does not necessarily qualify it as an adequate tractor. As an agricultural engineer, things such as drawbar pull, floatation, compaction, weighting, and a PTO for implement attachment points are some of the first things that crossed my mind when I got a quick glance at his “tractor” that he built in six days. Will his equipment work on a very small scale for the “average joe” who wants to tinker around and start their own farm? Probably. Is it a better solution for a third world country with limited resources, and better than pulling a plough with a donkey? Absolutely. Will his equipment hold up for anything more than that? I am highly skeptical. I did find a more recent video (2011) of Marc outlining his project in more detail, as well as some of the plans for his machines. After watching this video, I do have a bit more confidence that they will meet the job requirements because he claims that each machine will meet industry field testing and specification standards. However, I am still skeptical of how the cost analysis was done for the machines. Starting at 2:56 in the video, a chart is displayed comparing the cost of his machines to comparable machines used in industry. According to his chart, it looks like the cost of a skid loader built is only a couple hundred bucks?! I do condone the fact that he is developing CAD models for each piece of equipment, and has even hired developers full time provide free CAD software for the builds.

Question B: The New Yorker magazine recently had a fairly critical article regarding Marcin's OSE project. Find/link that article and summarize its critique. Marcin had a response to that: I'd like your response to both of these pieces.

In response to the New Yorker article: I think the author is poking a lot of fun at Marcin, which I guess is necessary to keep the attention of the audience as a journalist. I don’t think I would be so hard on somebody who is trying to do something for a good reason. However, some of the cracks at Marcin and his utopian self-sufficient community are valid points. I also had a hunch that Marcin is probably having trouble finding qualified workers to help construct his projects which seems to have been confirmed in this article. I can’t really say if I like or dislike the article. I am indifferent.

In response to Marcin’s New Yorker article response: I really liked how Marcin responded to the heavy criticism of the New Yorker article. He thoroughly broke down each point of criticism that the author of the New Yorker article brought up, and either defended himself/his community or elaborated on how they are making progress. For example, the author of the New Yorker article basically stated that the workers that typically come to help Marcin are highly unqualified to perform the necessary hands on work. Marcin admitted that this is sometimes a problem, and specifically outlined that he and his team are doing their best to continually upgrade the living spaces of the Factor e Farm so that it attracts better candidates. He also specified that his project is more than just for self-sufficient communities, which definitely made it more clear to me what his goals are. Also, after viewing the video Marcin had embedded in his response to the New Yorker article which highlights the progress made in 2013, I have higher hopes for his machines. They clearly have been able to perform their function, but I still would like to know the true reliability of his rudimentary craftsmanship. Marcin's 2013 progress video can be found here. I had to join vimeo to view the video, so if it does not play right away, that is probably why.

Question C: Imagine we want to create capabilities similar to what Marcin has made at PSU (something like an OSE student club, or another effort). I don't think the administration or trustees would support such a thing, but there might be professors who are interested in supporting such a thing. Do you know any of them? What do they do, and why do you think they would be interested in such a project? Imagine you are looking for allies to do such a thing. Whom is on your list and why?

Response to Question C: If an OSE student club or something similar were started at Penn State I can think of one professor that would be interested. His name is Douglas Schaufler and I am currently enrolled in his class which covers internal combustion engines for agricultural applications. The class covers all types of engine platforms from small Briggs and Stratton gasoline engines that would be used in something like a lawn mower, to heavy duty diesel engines that can power large tractors, agricultural equipment and could provide adequate power generation for a small community. The class not only covers design theories and practices, but also has a designated lab time for tearing down engines and rebuilding them to their original state. The professor who teaches the class has had thirty plus years of experience working at Caterpillar, one of the most successful large industrial equipment manufacturers in the world and is extremely knowledgeable in the field. He also has done extensive research for Penn State in alternative fuels such as vegetable oil and biodiesel for compression ignition engines. These fuels are renewable and widely available through the fermentation of natural sugars available from crop waste/residue such as the corn stalk or leaf. If properly refined, these alternative fuels can serve the same purpose as current petroleum products that we rely on foreign countries for. This professor also grows his own fruits and vegetables as the seasons allow, so he is knowledgeable in proper crop management and harvesting techniques.

Blog 3: Kanas City Teen Makes 3D Printed Prosthetic

Who created this design and when/where was it done? - Ivan Owen originally designed the 3-D printer “Robohand” with Richard Van As, a South African woodworker. Richard Van As was originally inspired to make a prosthetic for himself after losing a finger in a shop accident. Then, he found Ivan Owen, a puppet designer who worked with elaborate extremity functions and the two came together through online communications to design the 3-D printer "Robohand".

If you wanted to make one, where would you go to get it? - The files for the 3D printed prosthetic hand are on thingiverse!

How many news articles can you find which reference this technology? - A quick Google search found many, many related articles. Here are just a few...

Dad Uses 3D Printer To Make His Son A Prosthetic Hand

Using 3-D printing to address the need for prosthetics in Uganda

3D printed prosthetics: How a $100 arm is giving hope to Sudan’s 50,00 War Amputees

Teen’s inexpensive 3-D Printed Prosthetic could Aid Amputees in Third World

Prosthetic Hands that can be made from $5 to $1000 dollars

Faith in humanity restored!

Blog 4: Reviewing Classmates' Responses to Marcin's OSE Project

After reading many of my classmates’ responses to Marcin’s OSE project I found that I had many thoughts/ideas in common as well as many differences. The first response that I read (Drew Golterman) made me think of something that I had not discussed in my response. He did not necessarily mention this in his response, but after reading his I thought it would be interesting to conduct a study on how much it will cost a person to buy all the tools necessary to make one of his simplistic machines, versus how much it would cost to buy the machine. If a person is planning on making more than one of the machines, then in my opinion it would be worth investing in the proper tools. However, if it is a one time and done shot at building one of his machines to save some money, it may be more expensive to buy all the necessary tools than it would be to buy for example, a consumer brand skid loader.

One point that Kevin Moyer made that I thought was a great point and was worth including in this response was that if something critical were to fail on one of the machines, a person who just blindly followed an instruction manual may not know how to diagnose or troubleshoot the problem. This would result in long down times of the machines, and if they are critical to the crop production or survival of a small community then obviously this could create a huge problem. However, I think it is great that Marcin is holding workshops to formally educate more and more people on the design, maintenance and troubleshooting methods for his machines. I was not aware of this or must have not picked up on it in the most recent video I watched as Kevin shared.

I also read Sam Carroll’s response, and found it very useful with the links he provided to the overview of the OSE tractor progression as well as the link he provided to the interview of Emily Eakin. I was kind of shocked when I watched the in person interview of Emily Eakin because all her comments, ideas and views on the OSE project seemed very positive during the interview video. However, as we all know from reading her article, her views and thoughts written for the New Yorker article were very condescending and pessimistic. In my opinion she went out of her way to bash Marcin’s idealistic and humanitarian views as well as the people who were contributing to Marcin’s project. Her article was written in such a way that I believe it could completely turn a person off from any further investigation of the project and thus turn away a potentially valuable contributor.

One simple, but very important point that Zach Cameron made that I actually didn’t mention in my response was that if the OSE project is meant partly for developing countries, they will probably not have access to the internet. This proves to be an extremely big problem in my opinion. So, unless Marcin finds a way to personally hand deliver the contents of his OSE civilization starter kit, or has a plan for distributing his designs through a network of people, I don’t see how they will make it to developing countries.

Lastly, I read Tom Vasso’s response and it made me think of a very important point that is related to the last paragraph. In order to build these machines, it is necessary to have very advanced tools like welders, lathes, band saws etc. Many of these tools require more than standard household electrical service of approximately 200 amps. A large machine shop such as the one needed to build any of the OSE project machines should probably be outfitted with a 3-phase connectors and have a supply of at least 350-400 amps to be running everything simultaneously. How is any developing country going to be able to get that much electrical power? They would have to first invest in some large diesel engines for power generation and get all the proper electrical wiring/components. It just doesn’t seem that feasible when I think about this.

Blog 5: Examining the SCRUG Members' RepRap Media Timeline

An event very important in the progression of 3D printing technology (open source or not)

I think one very significant event that occurred in March of 2012 was 3D printing from an android device. I think this is so significant because I believe as we learn more about 3D printing, and the process becomes more efficient and repeatable that it will become commonplace to the general public. I think back to how rapidly cell phones evolved over time and would use this as an analogy of how 3D printing may develop. I think about when I got my first cell phone at 12 years old, which was earlier than most kids in 2002 and how it was so big I couldn’t fit it in my jean pockets. I simply had to carry it everywhere I went or put it in a backpack. The cell phone could speed dial a maximum of 10 contacts and if you wanted to send a text message it would cost you $0.15 and be a maximum of 150 characters. Now, I can use my cell phone to view a PDF, track a flight or lost baggage, play a video game online, send email, text message or group chat, manage my bank account, browse the internet, check where the nearest bus is, remind me to do something based on location, check the weather, video chat with family, function as my alarm clock, and the list goes on. It truly is incredible how far they have come. Seeing how far the cell phone has come in 10-12 years leads me to believe that 3D printers in a home will be a common thing, and there will be an app that everyone can get for their smart phone to print out some cool object they found on Pinterest or other website. So, the fact that android has already began to develop such applications solidifies my beliefs that 3D printers in many households is in the not too distant future.

A not so important event in the progression of this technology (something overhyped perhaps?)

One not so useful item I found was in May of 2012 when a fully functional lathe was made with 3D printing. In my opinion this is kind of counter intuitive. The whole point of 3D printing is so that any object can be made via additive manufacturing so something like a lathe would not be necessary. I guess I don’t understand why somebody was so adamant about proving that a 3D printer could make “useful items”. The whole reason 3D printers are taking off so fast is because people recognized their ability to make useful items. If people thought they could only make useless items the idea would have died long ago.

Something which you found interesting which you would like to think or speak more about.

Something I found interesting which is discussed many times throughout the media timeline is the use of 3D printers to manufacture guns or weapons. 3D printing actually first caught my attention back in high school because I am a gun enthusiast and came across an article about a “3D Printed Gun”. I was immediately skeptical because I thought there was no way somebody could have printed an entire functioning gun out of plastic, which turned out to be somewhat true, but I did see the potential of using them to print the lower receivers for assault rifles and anything but the slide and barrel for pistols because they are often made out of extremely tough polymers. In fact, a lot of times the weapons that include the use of extremely tough and weather resistant polymers are more desirable than an all metal weapon because they are

Blog 6: Projects that would be a logical next step...

I do not feel that I am qualified enough at this point in the semester to make any suggestions for the electronic systems or mechanical structure of the printers. However, I think one project that would be effective in improving the efficiency of how we work in the classroom/lab is visual organization of any parts for the printers, tools etc. I am slightly OCD when it comes to organization of a shop area, or any area that requires hands on working to perform a specific task. The reason I think it is so essential is because often times when tools and parts are not visually organized with a specific spot where they all belong I will spend more time looking for a part or tool than I actually spend performing the task I set out to do. It takes a little more time to put everything back where it belongs and organize everything, but that small amount of time is far outweighed by the time saved searching for parts. Some of the best car mechanic and tuning shops I have ever been to have immaculate shops where you wouldn’t ever find a tool laying out of place. I believe this is one key to a successful work environment.

One other thing I have been thinking about is a way to improve the printer beds. I am curious if there is a better way to apply a material quickly to the printer bed that is rough enough to allow the filament to stick to, but can quickly be changed rather than having to apply multiple strips of tape. Applying the tape takes time, and can actually be tough to make sure the tape is perfectly aligned and not overlapping which creates an uneven surface. I am thinking of a simple system where a roll of material the same size of the printer bed is mounted to the side of the printer and can quickly be pulled over the surface of the printer bed and cut. I think this would obviously help reduce the time it takes to apply the tape, and also ensure a consistency in the material used on the printer beds instead of mixing up different kinds of tape that don’t always allow the filament to stick.

Blog 7: 3-D Printed Lab Equipment & LEGO Atomic Force Microscope

I think this article just highlights another great use for 3-D printers. The possibilities for means of cheap parts for simple things that we often find ourselves paying a lot of money for is where I believe 3-D printers will continue to have the biggest impact over time. People will not only want them to make simple things for around the house and start small businesses, but they will also utilize them like they are discussing in this article to reduce the cost of lab research equipment. Obviously research is a huge way for less developed countries to further develop, create jobs, remain stable, and compete in the world market. So, cutting costs for the research equipment could be a crucial first step. I cannot think of any research equipment that we have made right now, however it is something I will look into.

I think this is pretty cool that students were able to make something as complicated as an atomic force microscope that normally costs $100,000 for $500. Obviously, I am skeptical of the quality, convenience, and user friendliness of it comparing to the $100,000 dollar production models. However, when proving that something can be made for a lot less using the most basic options available I don’t think anybody would expect it to compare. Hopefully they continue to develop their version of the AFM and come up with a kit that an average person, school or small company could easily afford to purchase and build.

Blog 8: Intellectual Property and 3D Printing

Copyright: the exclusive legal right, given to an originator or an assignee to print, publish, perform, film, or record literary, artistic, or musical material, and to authorize others to do the same.

Patent: a government authority or license conferring a right or title for a set period, esp. the sole right to exclude others from making, using, or selling an invention.

Trade Secret: a secret device or technique used by a company in manufacturing its products.

Trademark: a symbol, word, or words legally registered or established by use as representing a company or product.

Above are the definitions of copyright, patent, trade secret, and trademark for reference. Looking at these definitions we can easily see that copyright, patent and trademark all have legal rights involved so that others may not use whatever technology, logo, process etc. that is involved. I think copyright and trademark are set apart from patent because other people can pay to have access to a copyrighted or trademarked item. For example, people can wear Nike clothing but obviously have to pay for it, but they cannot legally print t-shirts with the Nike logo on it and sell for money. Also, somebody can pay to watch a copyrighted movie, but cannot legally record that movie and distribute it for free or money. However, it seems that if something is patented then nobody can use that technology, method, design or process no matter what until the IP time period is over. Trade Secrets will always exist, and are really the platform for which IP exists. However, if those trade secrets are not patented then they just remain trade secrets rather than IP. Trade secrets will always exist, but are always at risk of being compromised.

The five I’s are infringement, identification, impractical or impossible, and irrelevant. From the five I’s and reading this article I have concluded that the development of designs or new concepts for virtually every industry (aerospace, automotive, materials, health) will be increasingly more difficult to patent. Just as the encyclopedia was replaced by Wikipedia, I believe that open source will replace IP. As fast as technology and 3D printing are growing I believe it will eventually get to a point where claiming IP will be more of a worthless hassle. Another words, it will take more time to claim IP for a technology, concept or design than it will for somebody to come up with a new and better idea. Instead, I think companies will just invest that time, energy and money in research and development rather than filing for IP. I do believe trade secrets will continue to exist. There are always tricks of the trade to certain processes and I think a small startup company would keep their unique processes to themselves, especially if it sets their product apart from someone else’s. This is one way I feel IP may continue to exist. For example, if 3D printing company has a great hot tip design that truly sets their product apart from others, then they may try to patent that design to gain revenue and stay ahead of their competitors.

I could not find “creative commons” in either article for Blog 8.

Blog 9: Filament Reviews and Support Material

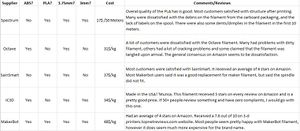

1: Below is a table I created from a few filaments I looked up and read reviews on. It includes ABS and PLA filament, the size it comes in and whether previous customers found the filament to be of good or poor quality.