Tiny Cut

Revision as of 13:48, 21 February 2013 by Marinosaurus (talk | contribs)

cut id

Release status: develloping

| Description | a tranfolding reprap

|

| License | |

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | LaserCut

|

| CAD Models | |

| External Link |

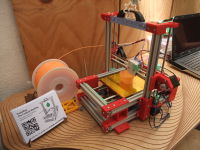

Throw a school projet we want to devellope an transportable laser cut. We batse our work the foldarap because we work in the same labo as Emmanuel.

Goals of this projet. We want to devellope this machine thow pre produce part or exstiting projet and technoligie. We want to be able in this projet to create a tiny laser cut portable in less than 4 month.

Contents

Concurence

With 600€ you go to an small laser cut http://www.ebay.fr/itm/High-Precise-and-High-Speed-USB-CO2-Laser-Engraver-Engraving-Cutting-Machine-/170934801974?pt=LH_DefaultDomain_3&hash=item27cc821636

Specifications

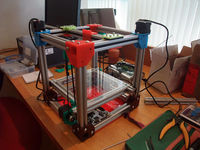

- Printed Parts: 20-21

- Non-Printed Parts: Laser tube, Power laser, optical part, laser water cooling, air boost,

- Cost: 400 €

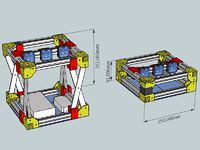

- Cutting Size: 200mm x 200mm

- Resolution : a voir ?? mm and ?? mm

- Speed: ?? mm/s

Special Features

- Mobile!

- Based on standard/cheap 20x20mm aluminium extrusion (with 6mm slot)

- Easy to build, with few tools (the printed parts are based on a 20mm grid (for overall aesthetic and mostly to ease the design), are generally 3-4mm thick, and fit the beams in a way you have nothing to measure during the assembly

- Whith a real CO2 laser tube

- Little (the entire machine is going to be about 30*30*30)

- Big RED Power Security (my favorite detail ^^)

- Cut surface about 200 x 200 mm

- Easy to place on the material (it the machine witch go on the material, not the material witch go inside the small machine)

R&D

[Forum]

Inspiration

Some details that I found interesting or related or want to integrate to this idea of a foldable machine...

External links, media/press, etc.

We like feedback from the community:

- marinosaurus page mention to be doing this project.

- User:Marinosaurus

History // forecast

- 2013/02: beggening

- 2013/03: Bills of mathérials, sourcing, buying

- 2013/04: Develloping CAO and printing test, Receving the part.

- 2013/05: Assembling work, and presentation of the projet for our shcool.