Talk:RepRap Morgan extended BOM

Hi Robert,

I too want to build a morgan but have been waiting for Quentin's updated instructions. I'm tired of waiting. Seeing stellar work like yours makes we want to build. The group in Charleston has put together some good material.

Interested in your work on the 12-z_bracket. Somehow, I have two of the z-brackets with the tear drop cutouts, one with a triangular back-plane structure, like in current github/stl for morgan, the other like yours with only the single back-plane.

Also, interested in your use if the steel drive shafts. Where did you get your 15mm and 22mm pipe?

Thanks.

Steve

- Hello Steve,

- glad to see my work being appreciated. I found the steel tubes in our local DIY market.

- Both have a wall thickness of 1mm and are very smooth and strong and they were less expensive than in copper. You should pay less than 1,50€/m.

- Maybe standard steel-c-pipes (they have 1,5mm walls) would do it too. You'll find a lot of these at ebay below 2€/m.

Contents

info on captive nuts

Hi there,

Been waiting for response from Quentin for several days. Was talking with him about the drive shaft assembly, he described the nuts pressed into the sides of the 15mm pipe. Anyway, I responded back asking how far from the ends do the captive nuts get pressed into the pipe? and which end of the pipe goes on the threaded rod-do the captive nuts lead or follow, presuming their at one end. That's the question I've been waiting for an answer.

No response - very odd, historically he has responded very quickly. I know he's frustrated his instructions haven't been released.

So, I thought I'd reach out. If you can't help, I am going to the Charleston Makelab and ask angrychisel his opinion. Really wish I had better instructions. Have you made notes you can share? Thanks.

Steve

- Hello Steve,

- You should get the student version of Autodesk Inventor (it's free for students though). With that you can look at my virtual Morgan in every detail you need.

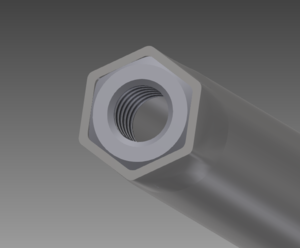

- The story with the 15mm pipe goes like this: On each end you press an M8 nut up to 80% of its height into the pipe. This bends the ends of the pipe into the M8-shape (you can see that demonstrated in the extended BOM in the "Hardware"-part). So when you screw the pipe onto the threaded rod (with M8 nuts inserted in both ends) the shaped ends of the pipe hold the M8 nuts and it acts like a very long nut itself. Quentin uses this technique to stabilize the threaded rod so that it doesn't bend while printing (the threaded rod alone is not strong enough over long distances).

- To press the M8 nuts into the pipe you screw an M8 nut on an M8 bolt. Then you insert the bot into one end of the pipe until the nut stops the insertion. Then you can press the M8 nut further into the pipe by knocking the M8 bolt into the pipe with a hammer.

- With a copper-pipe this is quite easy and doesn't need much force. With a steel-pipe you should support the M8-shaping of the pipe by using a vice on the pipe-end with the M8 nut in it. It is not necessary, that the nuts fit absolutely perfect, because they will stay firm once the pipe is screwed onto the threaded rod.

- The direction of the pipe doesn't matter, because its symmetrically.

- My virtual Morgan as a basis I want to make some small animated videos as assembly instructions. Or maybe someone is so kind to help me with that. It's a lot of work. But the model is there and realistic in every detail.

- If you need more tips, feel free to ask.

- About Quentin: I guess he just lost overview about all the questions in the forum. He is still answering fast, as far as I can see it. Maybe he just forgot some older questions, because he's quite busy I think.

- Greetings

- --RobertKuhlmann 20:22, 4 September 2013 (UTC)

re-peat captive nuts

Hi Robert,

I must be just thick-headed. You gave a detailed response. Mostly made sense. Thank you.

The problem I have is I keep expecting to see nuts pressed into the sides of the 15mm pipe.

Every image shows nuts on the threaded rod, only.

Quentin did get back with me. I responded to his 'Lillian' post and asked again. His answer made me a little confident. "Press the nuts in the sides near the end of the pipe." Again, never seen an image. Likewise, don't understand their use being horizontal to the vertical threaded rod. Never see ref to inserting a bolt across the pipe into the captive nuts..

I got my drivewheel hole widened to fit my 3/4" copper. So, I may be on the cusp. I didn't get an email when you updated this-I'll keep an eye open.

Thanks.

Steve

- Hello Steve,

- do you mean you missed a picture like this one?

- The pipe has a nut on each end. This is to stabilize the threaded rod, so that it doesn't bend while printing. The threaded rod alone would be able to twist and bend a bit over its length. With the steelpipe around it, fixed by the two nuts, this doesn't happen.

Hi (Not sure about this editing) No - not at all. The image I'm expecting has the nuts pressed into the sidewalls of the pipe.

- Hm. Why should you? The nuts are pressed into the pipe on each side/end. They are not pressed into any wall or into the wall of the pipe. That wouldn't make any sense.

- I think you just didn't get Quentin right. He means it in the exact configuration I showed to you.

- Regards

- Robert

Hi Robert, Exactly my thoughts. But Quentin sent an explicit email where he described pressing the nut in the side-wallof the pipe. That's the whole 80% insertion depth. Maybe I misread the original 'drive shaft assembly' section. Thanks for your help. Guess I'll skip it.

Steve

Extruder block

Hi there,

Do you have and work done on the extruder block, idler, gear

- You find the resp. parts in the extended BOM. But they are only repaints of the Prusa-extruder-parts. The RepRap doesn't need a special extruder, except is has to be a bowden type.

I've got my frame built and trying to work the details. Motors get installed tomorrow. Not sure how the Z-motor attaches - only have 2 motor mounts.

- The z-axis-motor is placed on the top-platform, the motor-axis pointing downwards. The axis is coupled to the lead-screw via the leadscrew-shaft-motor-mount.

After following your GREAT work, and a bit of Quentin's I've got a few pieces still in the box.

Tightening cones ? Never saw a place for them.

- I don't either.

Where do the hall endstops go and what are the details for the magnets.

- There's a detailed descrition in Harley's forum. I will transfer it to the wiki later on.

- The holders go to the smooth rods of the z-axis, right above the resp. drive wheel. The magnets are placed in one of the small round pits on every drive-wheel. The endstop holder holds the sensor in a way, it can detect the magnet in the resp. drive-wheel.

Also, don't even know where the rear bed-clips go.

- Take a look on my personal Morgan-Page here in the wiki: User:RobertKuhlmann/RepRap_Morgan

- You'll find some detailed pictures of the platform there.

Curious if my 3/4" pipe is too long - sticks out 3" above the upper platform.

- That's intended, because the moving arms shall not collide with the x-axis-stepper motor.

May be too far to the heated bed - should I plan on raising the bed. Measurement specs would have helped

- Maybe my Morgan-Page (User:RobertKuhlmann/RepRap_Morgan) can help here too.

6805 bearing adapter ?

- Yes. It holds contact between the 22mm-z-axis-pipe and the 6805-bearing in the z-mount-top, making the z-axis sit stable from bottom to top.

For Q:"Frame Assembly" #16, my 3mm bolts are only 6mm by the BOM, looks like the motor coupler needs more of a 20+mm 3mm bolt. Otherwise, where do these 6mm-3mm blots go? Keeps saying three for the motor coupler and I only see 2.

- The 3 M3x6mm bolts can be used as a replacement for 3 grub screws to fix the lead-screw-shaft-motor mount to the motor axis. You need to place 3 M3-nuts in the head of it. The lead-screw is fixed by two M3 x 20mm bolts with two M3 nuts.

Plus, all confused by Quentin's Q:"Frame Assembly" #17. Does the spring go inside the z-bracket? Plus, 8mm isn't long enough, the z-bracket is like 50mm wide. I didn't even get two leadscrew nuts. Quentin seems to want one on each side of the z-bracket.

- I'll publish a drawing for that.

Those and the bowden adapter are still in the box. Not sure where these pieces go. I need to ask Quentin too, but I may just focus on the extruder block with him. Sorry so wordy. Hard to find anyone ahead. Any help appreciated. You could email if you prefer at

- Answering question in public is preferred, because readers with similar questions may be interested in the answers as well.

Thanks.

Steve

- Answers are embedded in your text. And please don't forget to sign your posts (2nd last button above the editor window) --RobertKuhlmann (talk) 07:36, 25 September 2013 (PDT)

Leadscrew nuts and the anti-backlash spring

Hi there,

Looks good. What I expected except the BOM only lists one (1) leadscrew nut. Guess I'll need a second made.

Suggestion, maybe you add the dimensions of the spring? Diameter and length? Drawing is solid. Thanks.

- Done. I've corrected the quantity in the list and added the dimensions of the spring to the assembling instructions. --RobertKuhlmann (talk) 14:31, 25 September 2013 (PDT)

ML6 - Detail C, toolhead

Hey there,

Just reviewing my build. Looking at the ML6.pdf, noticed detail diagram C. I see the two screws that connect toolhead to the arm. However, you left off the two bolts, M3 I think, that are used to secure the J-head - maybe 20mm. I guess it needs nuts too. Want to help make those diagrams nice - I know I needed them. Thanks for your work.

- You're welcome. I'll correct that. Over the time this project will become better and better. :) I love it. --RobertKuhlmann (talk) 00:19, 26 September 2013 (PDT)

- And done. --RobertKuhlmann (talk) 00:33, 26 September 2013 (PDT)