File list

This special page shows all uploaded files.

| Date | Name | Thumbnail | Size | Description | Versions |

|---|---|---|---|---|---|

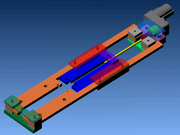

| 13:51, 22 January 2011 | MetalExtruderOverview.jpg (file) |  |

238 KB | syringe pump metal extruder overview | 1 |

| 22:47, 1 August 2012 | MetalMandrel01.jpg (file) |  |

116 KB | 1 | |

| 13:54, 22 January 2011 | MetalSyringeParts.zip (file) | 75 KB | stl and dxf format CAD files for syringe pump metal extruder | 1 | |

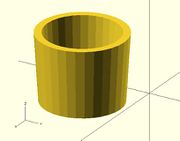

| 20:40, 13 October 2013 | MinimugSTL.jpg (file) |  |

24 KB | OpenSCAD render of the minimug object, a RepRap's traditional first print. | 1 |

| 13:56, 3 November 2013 | Mostly complete machine.jpg (file) |  |

233 KB | 1 | |

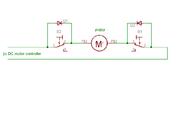

| 12:46, 18 July 2010 | Motor.jpg (file) |  |

46 KB | motor assembly with gears simultaneously meshing with rack | 1 |

| 12:48, 18 July 2010 | Multigear.zip (file) | 82 KB | This is MATLAB code that calculates center locations for two gears that are in simultaneous mesh with a third gear and a straight rack. | 1 | |

| 00:23, 15 September 2013 | My Parts 0.jpg (file) |  |

38 KB | 1 | |

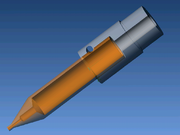

| 14:28, 22 January 2011 | NozzleParts.jpg (file) |  |

92 KB | 1 | |

| 14:28, 22 January 2011 | Nozzle asm.PNG (file) |  |

291 KB | 1 | |

| 14:28, 22 January 2011 | Nozzle asm1.jpg (file) |  |

176 KB | 1 | |

| 14:28, 22 January 2011 | Nozzle asm2.jpg (file) |  |

158 KB | 1 | |

| 14:28, 22 January 2011 | Nozzle stand.jpg (file) |  |

161 KB | 1 | |

| 13:42, 9 November 2013 | Nut and bolt assembled.jpg (file) |  |

72 KB | 1 | |

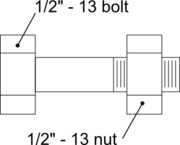

| 13:50, 9 November 2013 | Nut and bolt drawing.png (file) |  |

7 KB | 1 | |

| 13:49, 9 November 2013 | Nut and bolt unassembled.jpg (file) |  |

79 KB | 1 | |

| 18:00, 21 January 2011 | PaperInstructions.JPG (file) |  |

41 KB | order of gluing operations for assembling a compliant mechanism | 1 |

| 01:26, 15 September 2013 | PiezoPlates2.jpg (file) |  |

69 KB | 1 | |

| 01:07, 15 September 2013 | Piezo Circuit.PNG (file) |  |

488 KB | 1 | |

| 23:23, 14 September 2013 | Piezo Plates.pdf (file) | 282 KB | 1 | ||

| 00:24, 15 September 2013 | Piezo Testing 01.jpg (file) |  |

68 KB | 1 | |

| 14:28, 22 January 2011 | PlateAndCup.jpg (file) |  |

214 KB | 1 | |

| 14:28, 22 January 2011 | PlateHeaters.jpg (file) |  |

196 KB | 1 | |

| 18:05, 10 May 2013 | Printed PVDF bimorph actuator.JPG (file) |  |

18 KB | 1 | |

| 18:12, 14 December 2014 | Prusa-i3-build-files-screencap-dec-14-2014.JPG (file) |  |

172 KB | 1 | |

| 14:28, 22 January 2011 | PumpSwitches.jpg (file) |  |

142 KB | 1 | |

| 01:10, 10 November 2013 | ReprapBounty 01.jpg (file) |  |

159 KB | 1 | |

| 02:03, 10 November 2013 | ReprapBounty 02.jpg (file) | 27 KB | 1 | ||

| 02:06, 10 November 2013 | ReprapBounty 03.jpg (file) |  |

81 KB | 1 | |

| 02:08, 10 November 2013 | ReprapBounty 06.jpg (file) |  |

97 KB | 1 | |

| 02:10, 10 November 2013 | ReprapBounty 07.jpg (file) |  |

88 KB | 1 | |

| 02:12, 10 November 2013 | ReprapBounty 10.jpg (file) |  |

51 KB | 1 | |

| 01:15, 10 November 2013 | ReprapBounty 11.jpg (file) |  |

133 KB | 1 | |

| 01:06, 10 November 2013 | ReprapBounty 12.jpg (file) |  |

171 KB | 1 | |

| 01:32, 10 November 2013 | ReprapBounty 13.jpg (file) |  |

51 KB | 1 | |

| 22:49, 1 August 2012 | Results01.jpg (file) |  |

210 KB | 1 | |

| 22:49, 1 August 2012 | Results02.jpg (file) |  |

303 KB | 1 | |

| 18:24, 14 December 2014 | Rostock-mini-pro-build-files-dec-14-2014.JPG (file) |  |

157 KB | 1 | |

| 14:28, 22 January 2011 | Rotary switch.jpg (file) |  |

179 KB | 1 | |

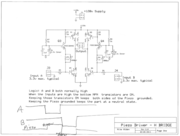

| 14:28, 22 January 2011 | Switch circuit.png (file) |  |

8 KB | 1 | |

| 14:28, 22 January 2011 | SyringePump motor.jpg (file) |  |

156 KB | 1 | |

| 14:28, 22 January 2011 | SyringePump syringe.jpg (file) |  |

183 KB | 1 | |

| 14:28, 22 January 2011 | Syringe pump asm.png (file) |  |

279 KB | 1 | |

| 13:54, 3 November 2013 | Toolhead closeup.jpg (file) |  |

281 KB | 1 | |

| 00:00, 1 September 2013 | Transparency 01.png (file) |  |

560 KB | 1 | |

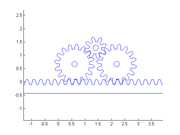

| 13:40, 18 July 2010 | TrigearsExample4.png (file) |  |

5 KB | example output of MATLAB gear center distance program | 1 |

| 16:53, 10 April 2010 | WaxVacuum3.jpg (file) |  |

74 KB | wax vacuum image | 1 |

| 01:40, 11 April 2010 | Waxuum1.jpg (file) |  |

78 KB | First attempt. This is just a single-tube needle with a heater and thermistor. The air tube is stuck in place with caulk. The lid, heater, ports, etc are held in place with JB-weld. This design did not work at all because there was not sufficient heat | 1 |

| 01:51, 11 April 2010 | Waxuum10.jpg (file) |  |

146 KB | Wax master, silicone mold, polyurethane part. | 1 |

| 01:49, 11 April 2010 | Waxuum11.jpg (file) |  |

138 KB | Closeup of case at beginning of test. The wax inside is molten so the interior is visible. Near the top of the case interior, note the slanted cut in the drain tube, where the thinner vent tube passes out and outside. Molten wax exits from the slanted | 1 |