Smartrap mini

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

NOTE: this page is in writing mode, estimated finished state : november 01 2013.

Release status: working

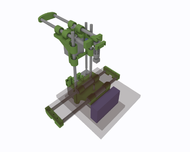

| Description | Smartrap mini is a small but strong reprap designed to be really easy to build and maintain.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Media:Smartrap-mini-0.1-first-print.mp4

Vision : goal

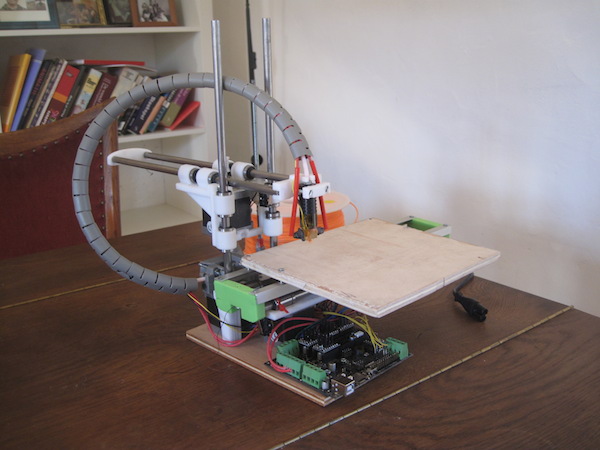

Real Reprap : most of the structure should be printed, so it can print itself for friends. Only the common base should be bought on special shops ( motors,hotend,controller).

Simple to build : I mean it! . No need for special tooling or ultra precision cut or drill or even adjustment. The final goal would be: no screw and everything come together by snap (almost).

Open source : for longevity.

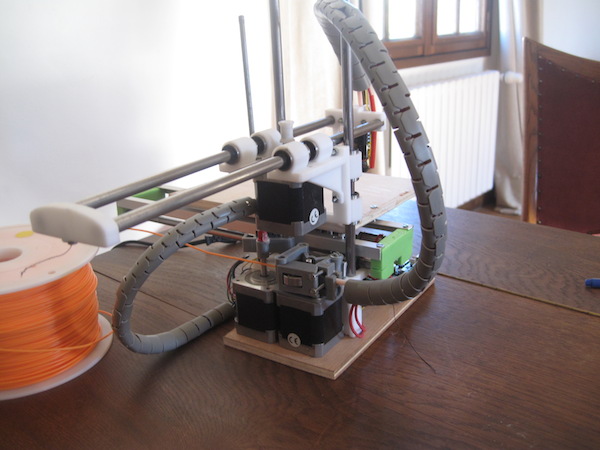

As cheap as possible : fishing line, printed bushing if possible ( not working for me now) , cheapest electronics..

Open to experimentation : Aluminium rails with 608zz, fixed axis with moving hotend, moving axis with fixed hotend..etc ( you should see photos down there).

The goal is not to have the best top notch ultra precision 3d printer, but to have a simple to build and adjust working printer. Easy reproducible to spread the world.

Features

Print size : from 150x150x150 to around 250x250x200. The first prototype is 200x200x150.

PLA only : It's a political decision: Even if ABS gives better results , i really don't like the fumes and the ecological impact. PLA , beeing compostable and asking for only 60 watts alime, is far more interesting to me.

Layer height : not really tested for now, looks like 0.2 works well.

Actual state and implemented features

The first model is working well. Better than we would think in fact. It's just nice to see how stable it is even it looks so small. That comes from the design choice of using 3 nema17 stepper motors as a structural base , that makes a very strong and heavy base ( 1,5 kg of steel metal).

Of course, lot of improvements are already in the list. The main concern was about the stability of z rods as we use plastic and not wood or aluminium. We use actually a bottom wood plank where we fix the base with a nice big m6 screw and it's very stable this way. There's no complicated operations on this plank but one hole to fix the big screw.