ScrewRap

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

ScrewRap

Release status: Experimental

[[image:|center|190px]]

| Description | T-Slot reprap using leadscrews instead of belts

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Design Goals

The following list summarise what the ScrewRap hopes to achieve:

- Minimal tools. I want assembly to be as easy as possible. The tools I'm thinking of are allen keys, screwdrivers and maybe a drill. This list may increase as time goes on, but not by much.

- Cheap. Even though I'm using leadscrews, I still want the rest of the printer to be as cheap as possible.

- Accurate. To achieve this the design requires a sturdy frame and precise linear motion components.

- Easy to source. I want to avoid custom made parts as much as possible, and use standard parts such as T-Slot, Stepper motors, Bearings etc. Where speialised components are required they will be 3D printed. The leadscrews may be slightly more difficult in sourcing than the rest.

Specification

- Printed Parts: ?

- Non-Printed Parts: ?

- Material Cost: ?

- Cost: ?

- Printing Size: 250mm x 260mm x 250mm (Needs checking)

- Resolution : XY = 6.25μm with 20mm pitch leadscrew; Z = 0.625μm with 2mm pitch leadscrew (1/16th microstepping assumed)

- Accuracy : 50μm positioning accuracy estimated

- Speed: ?

Development

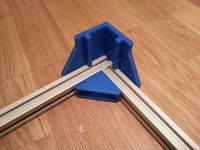

More will be uploaded soon. The following are the only photos I have currently.

Inspiration

The following list contains all the sources I've found inspiration or parts for this design:

- smartroad's Dual-Struder Fabricator. This is the foundation for my design, with everything else being built on top

- Jspark's Kid Mendel has the option to use leadscrews for all axes. He's also used threadless ballscrews which I may investigate in the future as a cheaper alternative.