Prusa i3 ION

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Prusa i3 ION

Release status: working

| Description | |

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Introduction

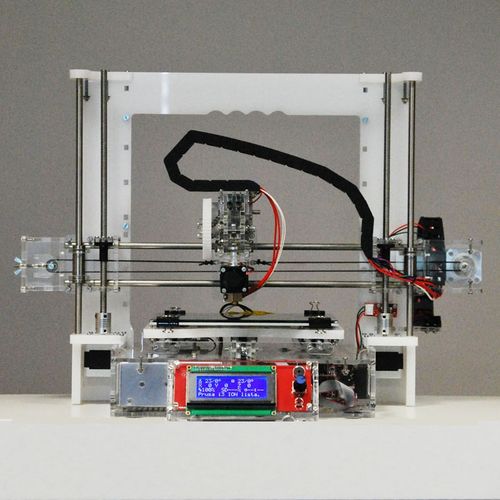

- The Prusa i3 ION is a 3D printer inspired in the Prusa i3, but with many changes, improvements and updates. It has been designed by the technical team of ThingiBOX, an online store whose products are related to the world of 3D printing.

- The project goal was to design a structure made with methacrylate where all the parts where cut by a CNC Laser Machine, the other goal was to keep all the electronics inside the printer making it look clean and tidy. To facilitate cooling of electronics there are fans working towards the shields.

- The maximum print volume is 200x200x150mm on a heated bed MK3 aluminum and above it a borosilicate glass (prepared for the abrupt change between temperatures), so it can be printed with ABS without any problems (if lacquer is applied).

- The extruder is a v5 E3D all metal that can heat up to 300 ºC. All kinds of plastic material (ABS, PLA, etc ...) available on the market can be used in this printer. There is the option of choosing the filament diameter that the extruder supports, so we offer it in 3mm or 1.75mm. The nozzle has an orifice of 0.4mm in both cases.

- There is also a fan (and its support) for the radiator of the extruder whose function is to prevent the filament clogging the duct.

- To drive the filament there is a gearwheel that magnifies the force that the stepper can do and drives a MK8 hobbed bolt.

- For the Z axis (the height) is recommended to choose the option that contains the bars Tr8x8 because that improves the print quality significantly.

- For the movement of the other two axes GT2 pulleys and synchronous belts are used.

- For the electronics; An Arduino MEGA 2560 in conjunction with a 1.4 RAMPS is used, also including 4 A4988 drivers that drive 5 NEMA17 stepper motors. 3 end stop switches are also included in order to home the axes automatically.

- To give the necessary power is also provided a power supply that outputs 12V and 30A (360W).

- Cables that are outside the base of the printer are confined in a cable chain in order to protect them during axis movement and making it look all tidy.

- At the rear of the base there are two connectors, one to connect with the AC power switch and one USB jack is embedded. It also has a space if you want to connect a Raspberry Pi (not included) to control the machine with Ocotprint through internet.

- In the options it is also given the possibility of adding a 2004 LCD screen as it is not necessary to print when connected by USB to a PC, but if you want to use it without a computer is recommended to choose the LCD as it incorporates a SD card reader.

Technical Data

| Frame | White methacrylate 10mm Transparent methacrylate 5mm |

| Smooth rods | 304 Steel, tolerance H9 |

| Threaded rods | Thread Tr8x8 or M8 (optional) |

| Print volume | 200x200x150 mm |

| Extruder | E3D v5 (All metal) |

| Filament diameter | 1.75/3 mm (optional) |

| Filament types | All types (PLA, ABS, Nylon, etc...) |

| Electronics | Arduino MEGA 2560 - RAMPS 1.4 |

| Drivers | 4 x A4988 |

| Power source | 12V/30A |

| Build platform | Aluminum MK3 Heated Bed (12-24V) |

| Display | LCD 2004 with SD card reader (optional) |

Documentation

Where to buy

- Complete Kit in ThingiBOX Now Available!