Prism

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: Experimental

| Description | Mendel Frame

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

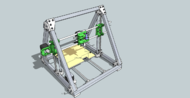

Prism Mendel

This extruded aluminum frame is a quick upgrade to your standard Sells Mendel. It makes it prettier and, more importantly, more rigid.

The design is finalized (mostly) but i'm still building, and don't want to post too much until i have it finished, so don't expect much more info/pictures till next week at the earliest.

design goals

I've always disliked how parts of the Mendel jut out. it's a minor complaint, but one I wanted to address as I moved to extruded aluminum. The Z rods are now inside the 'triangle', as is the z motor and y motor. The x axis can still jut out, but how much really depends on which x axis you choose, which isn't really part of this mod. It is much easier to travel with the Prism or make a case for the Prism because of this change. It also just makes the printer build area seem more open and accessible.

Another thing I want to try in the future is making a tent out of Mylar. The tent would hold in the heat from a heated bed and hot end and block errant air currents, but wouldn't get as hot as a heated chamber so overheating motors hopefully won't be a problem. This is going to be much easier to try with the Prism.

In addition, the y and z motors are in direct contact with the aluminum frame, which should dissipate motor heat nicely.

Unfortunately, for people who like Prusas, the frame won't allow top mounted motors as is. I think moving the motors to the base and using gears to drive the z lead screw is a good workaround if you still want two motors, but belt routing and tensioning is much easier with the Prism, so it might make a Sells-style single motor/belt more attractive again. Either way, a gear driven system also allows other gear ratios and takes care of the shaft coupling issue. However, if you prefer a pure Prusa, the MendelMax is a great alternative.

Another benefit of the Prism is a much larger Z build area(20-60 mm, hard to be precise because it depends mostly on your extruder and x axis) since the Y rods now sit below the bottom end of the Z rods. My Prism is 210mm from the bed to the X rods at ~Max Z, and all of this area is printable because the carriage will not hit the frame rods anymore. The x and y can also be increased, potentially.

Finally, most extruded aluminum profile suppliers cut to size for no extra cost, and the cuts are much more precise than you would get with a hacksaw at home. It's a nice extra that should make assembly and calibration easier.

New non-printed parts

(Misumi parts numbers are listed, where applicable, for easy ordering)

- Extruded Aluminum Profile

- 20x20x400 - 9 (HFS5-2020-400)

- M3

- M3x10mm SHCS - ~10-20

- M3 Nut - ~10

- M4

- M4x12mm SHCS - ~70

- M4 T-Nuts (which are compatible with your extrusion) - ~70 (HNKK5-4)

- M4 washer - ~140

- NOT REQUIRED M4 Post-Assembly T-Nut - 20 will run about $10 - makes it easy to attach parts without having to disassemble the whole frame. (HNTA5-4)

Printed Parts

Coming Soon!

Very Basic Build Instructions

Assemble your X Axis

You need the X axis at least partially assembled first, because the Z rods are trapped in the frame triangles when completed. Assembly instructions will vary depending on which x axis you plan to use, but generally, the X rods and belt can be left till later. The X ends should be assembled and ready to slide onto the z rods.

If you are moving from a Mendel to a Prism, you'll already have this done, though it'll be attached to your old printer :-). The Mendel is a lot harder to put together than it is to take apart, so print out all the parts you'll need to get up and printing first, because you don't want to have to re-assemble and calibrate it because you forgot something.

the first join: the Ztop vertex

First attach the Ztop rod holder, but just loosely. it's easier to put this piece in now then it is after you have the frame triangle assembled, but you'll need to triangle assembled in order to get it in the right position. move the two extrusion pieces till they just touch at the corners, and attach them together with one of the 60 degree plates. Put the 60 deg. plate on the side that the tightening screw will stick out of. Once the 60 deg plate is attached, you can secure the Ztop screws (Actually you must to this now, since it's really hard to do this once the smooth rod is in place, unless you have a short hex wrench) You now have a V shape with one 60 deg. plate and Ztop piece at the join.

The Frame triangle:

(Don't really crank down the screws until you know that you have all the pieces on the extrusion. It's annoying to have to remove a bunch of stuff just to slot in some t-nuts.)

Loosely attach two more 60 deg plates to each end of the assembled V. Now, take a Zbottom and attach it at the middle (200mm) of another piece of extrusion. There is a little center mark on each side of the Zbottom piece to help with your measurements. Also attach the z motor bracket and Z lead screw support; these can just be loose on the extrusion.

Slide the Z rod into the Ztop holder, and then bring the other extrusion with the Zbottom up and slide the rod into the Zbottom as well. to be clear, you are attaching the Z smooth rod to the Z rod holders, but you must do it in a particular way if you want it to go easily. Once the Z rod is in the holders, you can attach the 60 deg plates to the loose extrusion, forming the frame triangle. Make sure the corners of the extrusion are very close or touching, just as you did for the first join.

Now attach the inside corners.

Now, do the same thing for the other frame triangle.

Loose Nuts:

Please refer to the diagrams and add all the loose t-nuts now. if you don't, you'll have to loosen everything again.

Assemble the y stage:

Not as order-dependent as the z rods

influences?

Just yesterday I saw that sublime had posted a similar frame design about a year ago. It only bears a superficial resemblance to my design, but I just wanted to post it here to show that the idea isn't totally novel.