Print Troubleshooting Pictorial Guide

>>Currently under construction 2/23/2013- see [1]<<

This guide assumes a basically properly built and calibrated printer Main_Page. If you have not read through and attempted a complete calibration, see the REPRAP wiki for Calibration instructions. Some common calibration issues as well as common build related issues however are discussed.

The following categories are used to help identify the print issue by either print defects or by cause (if known). The print defects will point to identified causes and branch into individual examples and solutions:

Contents

- 1 CAUSES:

- 1.1 Material Feed

- 1.2 Material Handling

- 1.3 Material Handling, Material Contamination 01

- 1.4 Extruding Temperature

- 1.5 Clogged Extruder

- 1.6 Bed Adherence

- 1.7 Bed Adherence, insufficient 01

- 1.8 Print Speed

- 1.9 Calibration

- 1.10 Skipping Steps

- 1.11 Part Temperature

- 1.12 Part Temperature, too hot 01

- 1.13 Part Temperature, Too Cold 01

- 2 PRINT DEFECTS:

CAUSES:

Material Feed

Excessive

Insufficient

Intermittent

Material Handling

Material Contamination

Material Handling, Material Contamination 01

01 [[Image:|x150px|center]] 02 [[Image:|x150px|right]] 03

[[Image:|x150px|left]] 04 [[Image:|x150px|center]] 05 [[Image:|x150px|right]] 06

|

||||||||||||||||||||||||||||||||||||||||

Extruding Temperature

Too hot

Too cold

Clogged Extruder

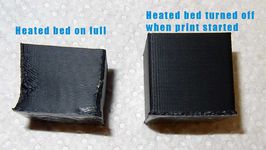

Bed Adherence

Insufficient

Excessive

Print Speed

Too Fast

Too Slow

Calibration

circularity

scale

Skipping Steps

Part Temperature

Too hot

Part Temperature, too hot 01

01 02 [[Image:|x150px|right]] 03

[[Image:|x150px|left]] 04 [[Image:|x150px|center]] 05 [[Image:|x150px|right]] 06

|

||||||||||||||||||||||||||||||||||||||||

Too cold

Part Temperature, Too Cold 01

01 02 [[Image:|x150px|right]] 03

[[Image:|x150px|left]] 04 [[Image:|x150px|center]] 05 [[Image:|x150px|right]] 06

|

||||||||||||||||||||||||||||||||||||||||

PRINT DEFECTS:

Surface Defects

Holes

Small Single Filament

Large Area of Filament

Waviness

Solidity of Surface

Strings

Blobs

Fineness of Detail

Filaments not Touching

Body Defects

Warping

Stepping/Offsetting

Interlayer Delamination

Failure at Height

Overall Disaster

If you are not certain about having correctly calibrated you printer, verify that it is calibrated first as that is the first step. See Calibration. Verify you also calibrated your extruder. Then verify your extruder zero height (endstop position) above your print bed is appropriately set.