PonokoXAxisAssembly

Assembling the Ponoko RepRap X Axis

| [PonokoRepRap Main Ponoko Page] | ||

| Prev Step | Next Step | |

| BOM for this page |

Please, read the instructions completely through before you start.

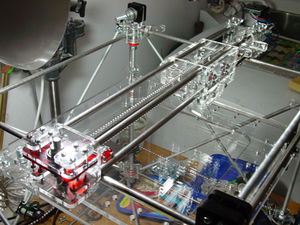

The X axis assembly consists of a motor bracket, a carriage and an idler housing all transfixed by four 500mm x 8mm diameter bright (zinc plated) steel rods. The X motor bracket can accept NEMA 17 or NEMA 23 stepper motors. Use washers under the heads of all screws unless told otherwise. Where nuts can freely rotate, there should also be a washer between the nut and the plastic.

DO NOT remove protective paper from the 3mm slides used in the exchangeable extruder socket. You're reading the instructions through, right? You'll find it mentioned here.

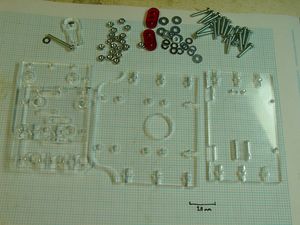

- 17 off M3x16 screws

- 1 off M3x20 screw

- 19 off M3 nuts

- 22 off M3 washers

Do not tighten the screws fully until all the parts of the carriage are in place. You may need the wiggle-room later.

Do not over-tighten the screws. This breaks the acrylic and means you either have to glue the bits together or hack a new part out of acrylic manually. Either will slow down your progress somewhat.

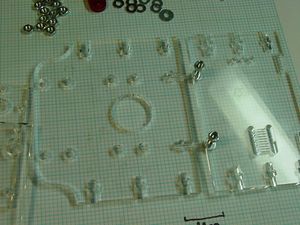

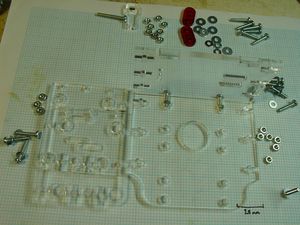

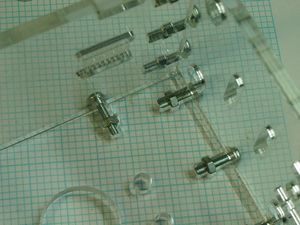

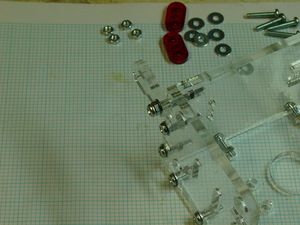

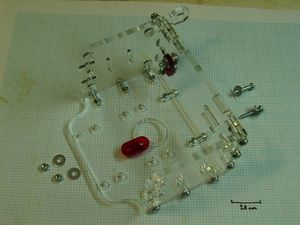

Put the <part p="3 M3">washer</part>s on <part>3 M3 16mm screw</part>s and put them into the 3 holes on the bottom of the side piece. Fit the side piece to the base, insert the <part>3 M3 nut</part>s into the slots and screw them in loosely. Add the <part>three M3 16mm screw</part>s/<part p="3 M3">washer</part>s and <part p="3 M3">nut</part>s to the right side of the carriage. Then repeat with the left side, with <part>three M3 16mm screw</part>s/<part p="3 M3">washer</part>s and <part p="3 M3">nut</part>s on the bottom but only fit the lower two of the <part p="2 M3 16mm">screw</part>s/<part p="2 M3">washer</part>s/<part p="2 M3">nut</part>s to the back of the carriage on the right hand side (shown un-assembled in the photo):

Gather the only <part>M3 20mm screw</part> and thread the <part p="M3">washer</part>, <part p="M3">nut</part>, and opto flag holder onto the screw to make a mechanical shish kebab. Do not fit the opto flag into the holder yet. We do that last as they are fragile and tend to bump into things during calibration.

This is what the kebab looks like. The first nut is because we need a non-standard length screw. You could just truncate the screw but this saves you the time and trouble. Fasten with a captive <part p="M3">nut</part>.

It's hard to show on the photos, but the chain clamps are actually on the inside of the box-like carriage structure. If you choose to use split washers (more in a sec.), put them on the <part p="four M3 16mm">screw</part>s first and then ordinary <part p="four M3">washer</part>s, the clamp, the carriage, <part p="four M3">washer</part>s and finally <part p="four M3">nut</part>s.

The clamps are not finished yet - we put the chain in them a bit later.

If you have some split washers handy, you might want to fit them on the screws that retain the chain clamps first. We don't know yet. They might help the chain stay firmly gripped as it beds in, or may give too much and let the chain slip. Experiment.

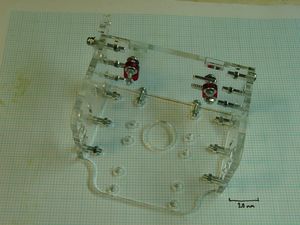

... and after all is done, your X carriage should look a lot like this one. Put it aside and save it for the next step, which is adding the socket for the exchangeable extruder. If you have the "redux" kit, the extruder is fixed with bolts through the obvious holes and there is no socket, so you can skip that part. Exchangeable extruders are handy if you want to run different materials regularly.

| [PonokoRepRap Main Ponoko Page] | ||

| Prev Step | Next Step |

-- Main.VikOlliver - 23 Oct 2008