PonokoExtruderAssembly

Assembling the Ponoko RepRap Extruder

UNDER CONSTRUCTION

Construction and assembly of the Extruder is quite demanding. There is a 3mm hole to be bored straight down a 40mm long rod, a 0.5mm hole to be drilled and some rudimentary lathing to be done. If you have a smattering of DIY skills, you should be able to accomplish this with a power drill and a few nifty tricks. If not feeling quite up to the challenge and unable to find a helpful person with a lathe nearby, buy the bits from the RRRF, Diamond Age, or BitsFromBytes.

Start by finding the components and fastenings as shown. Er, right. Better take a photo of that hadn't I?

Take a piece of M8 studding 110mm long and wind a nut down it about 60mm. Add two 680Z "sk8er b0y" bearings and a 12mm o/d M8 spacer cut from 4.5 or 5mm acrylic. Add the Extruder Bearing Stop, making sure the notch in it faces anti-clockwise when viewed from the top of the M8 studding as shown

Screw on another nut, add a washer and the 20mm o/d M8 spacer cut from 8mm acrylic. Screw on another nut, slip on the large gear wheel and secure with a washer and nut. Shuffle the nuts so that when the lower nut is helt against the neck of the 8mm Extruder Body, the bottom of the studding misses the end of its slot by about 1mm as shown:

Put them all together.

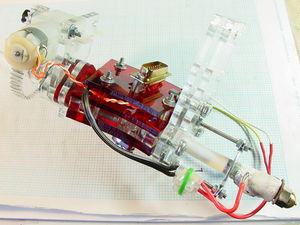

The final extruder all ready to plug in.

-- Main.VikOlliver - 29 Oct 2008