Polycaprolactone

-- Main.AdrianBowyer - 04 Nov 2005

Polymorph and Making Polycaprolactone Rods for RepRap

Polymorph

Polymorph is a nylon-like plastic that has a very low melting point (about 60 o C). Its strength and low melting point make it an ideal working material for the RepRap machine, and we are concentrating on devices for building with it, at least initially.

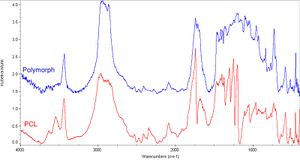

Polymorph is similar to polycaprolactone (PCL). But Jonathan Harris at Birmingham University kindly ran both through an FTIR for us:

and as you can see thare are minor differences around wavenumbers of 1100 and 3600 cm-1. I suspect that this is just a difference in molecular weight.

I have now (1 December 2005) obtained a sample of polycaprolactone granules and used it in place of Polymorph. It works perfectly to make rods for the RepRap extruder. I used granules of CAPA 6800 polycaprolactone (2-Oxepanone, homopolymer; molecular weight 80,000, CAS number: 24980-41-4) from

Solvay Interox Ltd. Baronet Works Lower Walton Warrington WA4 6HB U.K. +44 (0) 1925 643210

The Solvay website is here. CAPA 6800 is supplied by the company in 20 kg paper sacks, or 500 kg bags. Currently, it appears to cost USD$ 9/kg ("USD$ 4.05/lb for a 20kg bag, not including shipping"). Polymorph granules can also be obtained from the following suppliers:

UK:

Maplin Electronics Ltd. National Distribution Centre Valley Road Wombwell Barnsley South Yorkshire S73 0BS Sales: +44 (0)870 4296000

Link to the Maplin Polymorph page.

Middlesex University Teaching Resources (MUTR) Ltd. Unit 10, The IO Centre Lea Road Waltham Cross Herts, EN9 1AS

Link to the MUTR Polymorph page.

USA (Polymorph is called Friendly Plastic in the USA):

The Compleat Sculptor 90 Vandam Street West SoHo N.Y.C. Phone: 800-9-SCULPT

Link to The Compleat Sculptor Friendly Plastic page.

Sunshine Discount Crafts 12335 62nd St N Largo, FL 33773 Phone: 1-800-729-2878

Link to the Sunshine Discount Crafts Friendly Plastic page.

This company also supplies Friendly Plastic in a wide range of colours.

Making Polycaprolactone Rods

The extruder needs a supply of 3 mm diameter polymorph filament as input. If you can buy this cheaply, so much the better - many companies that make plastic welding rods will process quite small quantities of any thermoplastic into continuous filament.

But it is quite simple to make your own rods from Polymorph granules - the usual form in which the polymer is supplied.

To make your own rods first drill a 3 mm hole in - well, just about anything rigid; a scrap piece of aluminium about 10 mm thick is good. You will use this to pass the finished rod through to test that it is not too fat.

Next gather together the following:

- An electric kettle

- A 300 ml beaker (a clean coffee mug will do fine)

- A 3 mm diameter rod about 300 mm long to act as a reference. I used a silver-steel one, but again any rigid material will do (knitting needle etc.).

- A sheet of glass about 300 mm x 250 mm (the size is not critical, but don't make the large dimension much less than 300 mm).

- A 150 mm length of stiff wire (the single-strand copper used in house wiring is fine - in that case leave the insulation on all but the last 30 mm).

If the glass is freshly cut, smooth the edges with fine sandpaper so they will not cut you in turn.

%RED%Keep everything from here on very clean. Any bits of dust and dirt will become incorporated in the rod you make, and will then clog the extruder nozzle. This includes dirt under fingernails.%ENDCOLOR%

Measure out about 3 g of polymorph granules. If you can't weigh 3 g, then this is what 3 g of Polymorph looks like:

The individual granules in the picture are about 3 or 4 mm across. It's roughly half a heaped teaspoon of the stuff.

Bend the wire to form a right angle at the (insulation-stripped) end about 15 mm long. You will use this to hook the Polymorph out of the boiling water in the beaker. A metal fork will do.

Boil about 1 litre of water in the kettle, put the granules in the beaker, and pour boiling water over them. Fill the beaker about two-thirds full.

The Polymorph will melt and coagulate. Move the resulting lump about underwater with the hook to gather up any stray granules, then pull the lump out.

Using your fingers, squeeze out the hot water, and make the lump into a sausage about 50 mm long and 10 mm in diameter like this:

%RED%OBVIOUS WARNING: getting boiling water on your fingers from the Polymorph lump will scald you. Don't do it. Wait till things have cooled a little.%ENDCOLOR%

Now roll the Polymorph between the glass sheet and a flat surface such as a table top. When the Polymorph is hot it will squash under the glass very easily, and you will only need the lightest pressure. As it cools it will become more solid and need a greater pressure. The glass lets you see what you are doing.

%RED%ANOTHER OBVIOUS WARNING: If you push down too hard on the glass it will break, cut your hand, and spoil the rod you are making with a big red stain. Don't do that either.%ENDCOLOR%

Good results have been achieved using the rough side of two polypropylene chopping boards as rolling surfaces. They have a low heat capacity, don't readily stick, and grip the wet Polymorph well.

As the rod cools it will reach a point where it cannot be worked any further. It will probably look something like this:

Bend it, put it back in the beaker, reboil the kettle, and add new hot water. Take care not to let the Polymorph ends touch each other in the beaker as they will stick together. When the Polymorph is soft again take it out with the hook and repeat the rolling process. You may have to do this several times. When the diameter gets near to 3 mm, put the reference 3 mm rod (B) under the glass like this:

The Polymorph rod is labeled A. You will find that it naturally tends to roll next to the reference rod. With the fact that the glass slopes very slightly towards its bottom edge against the table, this gives a Polymorph rod slightly smaller in diameter than the reference rod (it will end up about 2.9 mm in diameter) - this is exactly what you want. (The reference rod in the picture is not bent - that's a distortion created by the wide-angle camera lens...)

Test the rod when it is cold by putting it through your reference 3 mm hole. It should not be lose, but neither should it jam. If it jams, reheat it and roll it down a bit more. If it's too lose, you've gone too far...