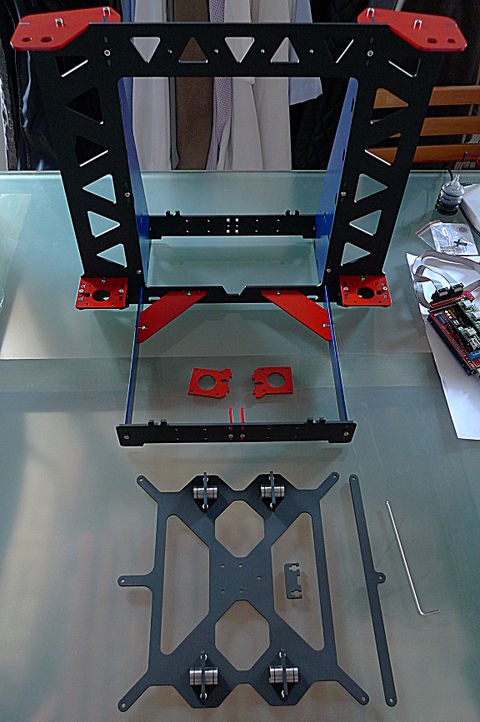

P3Steel main steel frame assembly

Now that we have all the steel parts painted, and having let the last coat of paint dry for at least 48 hours, we can begin to assemble our P3Steel:

The basic frame assembly goes very fast because there is nothing to adjust or check for accuracy. Putting together the main steel frame takes less than half an hour:

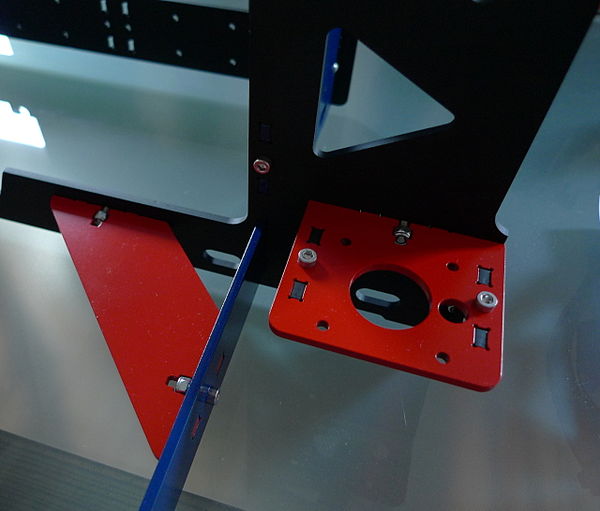

We only use 12mm M3 hex steel screws and nylock m3 nuts and so a single tool is required:

The accuracy of the laser cutting process guarantees the perfect fit of all the frame parts: