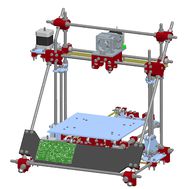

Orca v020

Release status: prototype

| Description | RepRap Orca

|

| License | GPL v2

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Index

RepRap Orca is the latest 3D printer in development by http://mendel-parts.com and well in short:

a cheap, not too heavy, but still robust 3D printer, easy to transport (grab it on the front X-bar at the sides..) and optimized for 1.75mm filament.

It still has a Mendel build size, but is simpler/faster to build. (with experience and proper manual, probably in one afternoon).

For this 3D printer not much hardware is needed, but it is still stiff with short bars and belts etc.

It doesn't contain too many (or too big, too complex) plastic parts, so is capable of fast reproduction

(each Orca can easily print a new Orca each day..)

--> Orca v0.2 will be released end of June 2011 (STL files, eDrawings, PDF's, STEP, IGES, DXF, basic manual etc).

Specifications

Benefits of this Design

- fast & easy to build (build time: 4-16hours depending on experience/manual status/finetuning needed etc)

- All plastics (incl extruder) can be printed in 15hours @ 50mm/s @ 0.32mm layers with 1.75mm filament

- Plastics are small & simple shaped

- only 4 simple cutting sizes for all threaded & smooth rod (in total: 10x330,7x400,2x500,2x265)

- short bars (max 400mm)

- short belts and simple routing/tensioning (3x 840/5mm wide or 1x 840/16mm wide cut in three)

- less bolts, nuts etc

- Very open frame

- very nice while building/working on it, highly accessible

- Printed Object good visible/accessible

- Extruder simple & small & very good visible/accessible/

- Smooth Z-axis & Z-axis moves down instead of up against gravity

- alot of the important dimension are in the thick sheet

- footprint roughly 28x35cm (excl: studding sticking out & Y-cluster sticking out backward etc, since powersupplies can be put under that..)

- printsize roughly 200x200x130

- Model is easy scalable

- Cheap @ mendel-parts.com :P

Orca Electronics

We are also developing new electronics, in short: a very deluxe GEN6 with alot of addons/new features, like standalone printing from SD, multiple heated beds/extruders possible, smart acceleration and a Touchscreen (4,3") and alot more at a very competitive price..

The project is currently named "gen6 ultra" but will change, for now probably "Orca Electronics" ;)

But then newcomers will think the "Orca Electronics" are specific to the machine, and won't work with a Prusa, 1X2, or This Week's Sexy Post-Prusa Mendel. :( --Sebastien Bailard 20:49, 18 May 2011 (UTC)

Current naming status: Orca Electronics aka: GEN6 Ultra / GEN6++ / Camiel's 2nd Generation Electronics / Mendel-Parts electronics v2 / naming still unsure etc

NOTE: current Orca v0.2 uses standard GEN6 and doesnt come with the touchscreen electronics yet..

Orca will be sold with the new touchscreen electronics probably earliest end of September..

How to get Orca

For Orca complete kits:

For Orca parts:

How to build Orca

The five stages:

4. Download, Install & use the print & firmware software

5. Finetune & test machine / firmware

Preparing

BOM

(Bill of Materials / What do I need for this Orca v0.2?)

- Printed Plastics

- Smooth Rod

- Threaded Rod

- Bolts, nuts & washers

- Bearings

- Belts

- Electronics & opto's

- Extruder parts

- Heated bed parts

- Motors

- Thick & thin sheet

- Power supplies

(? silicon sealant/cooling fan/cooling paste/kapton ?)

Printed Plastics

- 1x Printbed sm01

- 1x Printbed sm02

- 1x Printbed sm03

Smooth Rod

- 4x 330mm, 8mm diameter

- 2x 400mm, 8mm diameter

tolerances: +/- 5mm is probably ok..

Threaded Rod

- 6x 330mm, M8

- 5x 400mm, M8

- 2x 500mm, M8

- 2x 265mm, M8

tolerances: +/- 5mm is probably ok..

Bolts, nuts & washers

- this list is currently being finalised..

Bearings

- 38x 624ZZ (40pc needed with geared Orca extruder)

- 4x 608ZZ

Belts

- 3x 840mm T5 synchroflex timing belt - 5mm width

Electronics & opto's

- 1x Mendel-Parts GEN6 Electronics incl opto's

(this comes with the three opto's on cables and with wiring for the extruder (with a molex connector on one side, ferrules are used on the other side)

- 1x USB A-B cable (recommended: 3mtr length)

Extruder parts

- 1x Mendel-Parts hotend v9 for 1.75mm with .35mm nozzle (recommended, but others should work too with some fitting/adapting probably)

- 1x Mendel-parts hotend v9 heaterblock kit (will be including thermistor, heat resistor, cooling fan (+ extension cabling)

- 1x hightemp heatshrink 2.4mm around 20cm (for use with ferrules, see below)

- 2x ferrule of 0.5mm (connecting G550 thermistor)

- 4x ferrule of 1.0mm (connecting heat resistor & extending hotend v9 cooling fan cables)

- 1x Thermistor G550 (recommended for GEN6)

- 1x Heat Resistor

- Silicone sealant upto 300C (longterm 300C...) (for placing thermistor and heat resistor in heater block)

- Kapton tape 13mm (for the insulation of thermistor G550 legs)

- 4x springs for extruder

- cooling fan 40x40mm

- M4 brass insert piece with centerhole drilled out to 5.0/5.1mm for direct drive extruder (dont forget to remove grubscrew while drilling if you upgrade an old one).

Or alternatively with old version / Orca geared extruder, a standard m4 insert piece is used with M4 thread (in near future we will have an improved version and also in different materials etc.)

Heated bed parts

- 4x 1.5 Ohm heater block is recommended for Orca 4mm printbed, ideal with a 90W 12-22V powersupply, 12V=53C, 14v=60C .. 22V = 110C

- 4x printbed springs for orca 26Lx11

- 1x cabling for in between heater blocks, around 50cm long at least 0.75mm

- 1x PTFE sheet for use as strain relief (and optional under the springs)

optionally:

- 1x Cooling paste upto 150C (can be used in between printbed and heater blocks for better heat transfer, however I have serious doubts in how necessary this is..)

Motors

- 4x NEMA17 motors are needed for an Orca (preferable with 80cm cables), for the Orca extruder without gearing (latest version) high torque motors are necessary (and probably raising the potentiometer on the electronics too..)

All motor pullies now have grubscrews, but we still recommend to file a small flat side on the motorshaft, dont forget to use tape to protect the motor or use clay around the shaft. (I use wide insulation tape with a hole in it that fits the motor shaft tightly then there is a good seal and no metal swarfs are drawn in the motor (its magnetic..))

Power supplies

Thick & thin sheet

Required Tools

You will need a "standard" toolbox to build an Orca. That includes, but is not limited to:

- Metric allen key / hex wrench set - (2,5mm = M3 (and countersunk M4 bolts) / 3mm = M4)

- (Combination) Wrench set - (5,5mm = M3 & 7mm = M4 & 10mm = M6 & 13mm = M8)

- Dikes/needle-nose pliers/small vice grips.

- Measuring device, preferably a set of calipers or a decent ruler

- Scissors

- Wire stripper

- Small files &/or a dremel

- Drill & common bit sizes

- Countersunk drill (we will probably pre-countersunk Orca v0.2 thick sheet, however this is unsure yet..)

- side cutters

- Multimeter for checking powersupply connection, plus/minus

- Soldering iron and associated consumables (solder, sponge, wick, etc) for the heated bed.

Mendel-Parts.com GEN6 Electronics & opto's & motors are plugnplay out of the box, no soldering required for those.

Mechanical construction

Overview

Orca axes, concept etc

CAD Files

STP/IGES/STL/DXF/PDF/JPG etc

eDrawings & PDF sheets

We are currently working on a professional assembly manual with exploded views/BOMS etc, just like an Ikea manual.. first version will be released end June/early July.

- 5-page pdf sample of frame right assembly

- all current manual PDF's (under construction, use at your own risk currently)

Wiring & Electronics

How to use Orca

- 1. General usage

- 2. Software setup

- 3. maintenance of machine

- 4. Problem solving

Videos

- <videoflash type="youtube">VKCQ5vk_2fo</videoflash>

Orca nr 4 printing Orca nr 5 (18-5-2011)

Status

- Version 0.2, May 2011 a prototype serie of 12pc has been made/build and in June production start of first 100pc v0.2 after some delay, because of last minute new extruder and hotend for Orca (and also fits Mendel plug n play if you have Gen6..)

- Version 0.1, April 21, 2011, is the first prototype

Version 0.2

- more info soon

Version 0.1

- Some weekend in January, 2011 : The first basic concept has been drawn

- Some weekend in April, 2011: After on hold for some months, I've finished first files, printing the parts, building it.. and being amazed about it, even without any thick sheet (yet) its very solid... and it will be probably one printbed to print (excl extruder). So suddenly I start to realise that this printer is better then anything around atm (for the given selling price, since it will be cheap) and still has very high stifness and the shortest belts I've seen around (700/840/840mm) For those wo dont know, price of a 1380mm belt is around 2x the price of a 840mm and also long belts give alot more issues... Also the parts are very good printable/symmetric/etc and we are designing it all to have standard size bolts etc.. (alot of people dont know, but for example m4x35 is more expensive then m4x40.. so we focused also on using only a few standard sizes widely avaible etc.

(finally my many years of being a 3D CAD Engineer at a major product development office comes in use for the RepRap world...)

Calendar

June 2011

- Orca printbed stl files are online, check downloads/stl

- first production serie of 100pc of Orca v0.2 thick and thin sheet should arrive tomorrow

- Thick sheet files will be released in few days (PDF/DXF)

- The single printed part files of orca v0.2 will be released (STL/STEP/IGES)

- Three Orca's are in our production line now (beside the Mendels), printing three new Orca sets daily

July 2011

- first Orca manual (exploded views/BOM's in pdf) is planned for early July

- Orca build party @ Barcelona (?)

- first Orca electronics prototype testing is scheduled for end July/early August

PAST (who cares about that part, this world is going way too fast to look back..)

May 2011:

- first, very successful, Orca workshop held @ mendel-parts

- Orca was exposed on an exhibition @ TAC / Eindhoven, more info/pictures soon

Users

Camiel Gubbels is the lead developer/engineer/tester/supplier for this 3D printer. Mendel-Parts.com He's often in the IRC channel, if you need to ask a question.

FAQ

Q: Why is this new printer called "Orca"

A: someone in IRC kept misreading my Orsa (project codename) or well maybe on purpose not sure.. (Orsa = bear in Italian, since it looks a bit like a sitting bear (back in January... ), also Orca sounds better in English then Orsa.