Nophead's Extruder Tweaks

The extruder design has moved on, getting ever more complicated, but I have stuck with the original version with a lot of minor tweaks to make it reliable. It gives good results with ABS, PCL, PLA and HDPE and has higher throughput than any of the geared designs.

Starting from the top :-

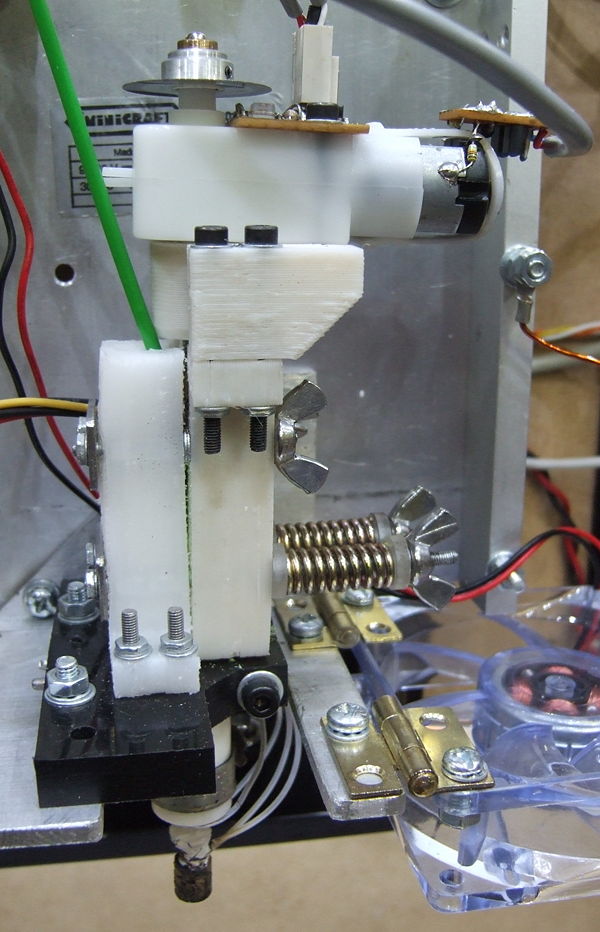

Shaft encoder

Using a shaft encoder gives the following advantages: -

- Ensures a constant filament feed, independent of friction and temperature.

- Allows the speed to be reduced without stalling, but also does not reduce the top speed as gears do.

- Requires no trial and error calibration of feed rate as it can be calculated from screw pitch, etc.

Details of my optical implementation here. Zach's magnetic version available from the [rrrf.org RRRF] here.

Interference suppressor

DC motors give off a lot of RF interference which can corrupt comms, crash nearby micros and affect radio and TV reception. I designed a small suppressor circuit which solves the problem. Details here and here. An RRRF version is under devlopment details here.

GM3 Gearmotor

- This must be the the 12V version. The 5V motor has very thin brushes that quickly wear away.

- The clutch may need locking for touch plastics like PLA and HDPE. See Zach's instructions.

- I have found that the output shaft sometimes starts slipping (even without the clutch being locked). This can be fixed by gluing it with a two part cynoacrylate superglue that states it is suitable for polyethylene and polypropylene.

- Running in the motor by connecting to a low voltage supply for a few hours will allow the brushes to wear in before having to handle high currents. This reduces arching, producing less RFI and prolongs the life of the brushes.

- Adrian Bowyer recommends lubricating the gearbox with silicone grease.

Direct drive

The flexible drive has limited life due to metal fatigue and is not required for any plastics tried so far. The direct drive motor holder for the older design extruder is hard to dig out of SVN so I have posted it here: Media:Old-motor-holder.stl

Pump

- The poly holder channel needs to be low friction, particularly for PLA. HDPE is ideal for this as it can be RepRapped and is is almost as slippery as PTFE.

- Lubricating the filament by passing it through an oiled felt washer can help with PLA, I have not needed it for other plastics and it tends to discolour the object being made.

- The pump halves are best spaced apart at the top by two or three washers so that the drive screw clears the filament. This gives a gradual lead in reducing the amount of friction needed to cut the thread. Only a relatively small section of thread needs to be engaged to move the plastic, any more just increases the friction.

- Two very strong springs are required at the bottom for hard plastics like PLA and ABS. Mine are 1.5mm x 9mm x 25mm and came from an A3 flat bed scanner's lid hinge. Note spring force is proportional to the fourth power of the wire diameter. I made end caps for the springs as the inner diameter is too big for M3. Ideally the studding would be bigger and the holes further apart.

- The screw drive works better if the thread is sharpened. This can be done by running a half round needle file along it while spinning it. Adrian Bowyer reports it can also be done with a split tap on its smallest setting.

- Wingnuts make it easier to assemble and disassemble. The M3 studding wears out eventually. Keeping it lubricated with a little grease helps.

- I use tapped steel plates with lock nuts on the other end of the M3 studding to make assembly easier. I.e. you don't need a spanner.

Clamp

The friction clamp does not hold the PTFE barrel well enough to extrude HDPE. There are two solutions to this. Adrian Bowyers is two 3mm pins inserted through the clamp and the barrel. I used smaller diameter pins out of pop head rivets. Vik Olliver puts a single self tapping screw through the clamp into the PTFE.

TBC