MetalicaRap

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: Experimental

| Description | Electron beam sintering tool head (EBS) and high vacuum chamber.(early development phase).

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

MetalicaRap Working Notes

Criteria ; Design a Metal 3D Printer , that produces dimensionally finished parts +- 1µ m over 20mm, largly self reproducing, electrical supply limited to single phase ( ie not 3 Phase,), minimum consumables beyond metal powder ( avoiding need for e.g.argon gas ... etc,),cost for parts less than a small car, buildrate can be slow i.e. .2KG per hour, no bigger than a wardrobe.

Due to lack of control in metal powder deposition in conventional ebeam 3D printing (e.g arcam 3d) a tolerance of 300µ in the Z axis is a typical with 10µ powder,( Lowder power sizes are prone to magnetic forces and typically unwieldy, though powder demagnetization and non ferrous construction is a possibility ), So using multi pickup(Scanning Electron Microscope (SEM) combined with Image processing the suedo stereo SEM picture data to true dimensional 3D data, Enabling sub µ metal height measurement. Z axis dimensional mistakes in any layer can be found and corrected using Electron beam machining EBM / ebeam vaporization of metal. This brings the XYZ axis to 20µ error over 20mm (T7). Future stage in development might include Ion beam etching gun to take dimensions to sub µ level.

This has 5 elements; electron gun, High Vacuum chamber, roughing pump, oil diffusion pump and metal powder dispenser.

Design Discussion Electron gun 3KW 100 KV hot cathode gun

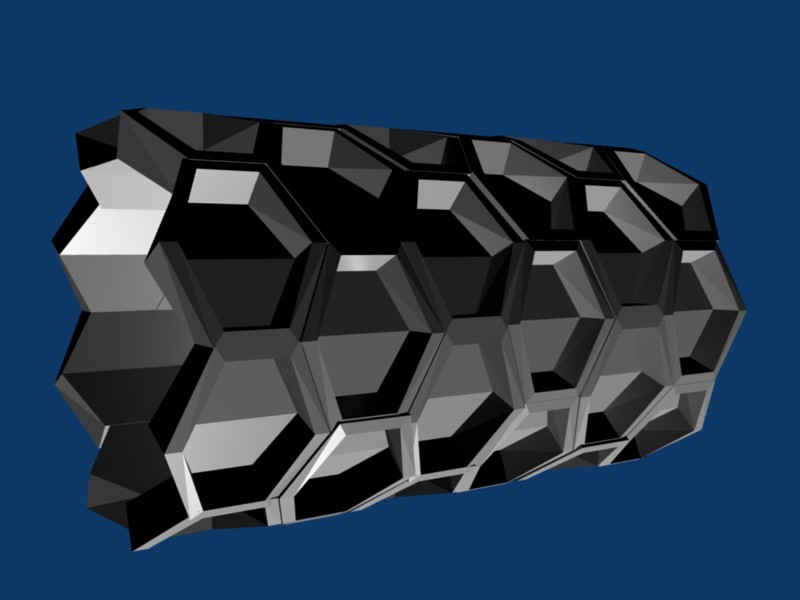

High vacuum chamber Stainless steel High vacuum 10-5 Tor / (mm mercury) NiCr Alloy (10-16) Hexagonalx40 halfhexagonalx16 endpiecesx16 384 bolts copper wire, future ; airlock so print while repump, main door Viton O ring (Euro ).

Roughing pump Vane pump ( initially purchased)

Oil diffusion pump using existing EBS build design

metal powder dispenser options include ; screw/ trough design; feed chamber build chamber; others

A rough sketch made in Blender of a vacuum chamber made from hexagonal parts printed in a MetalicaRap. Anders

'

Forum thread

Current status

Based in Copenhagen Denmark Labitat.dk Electron gun test repstrap vacuum chamber including pumps and gauges under electrical maintenance. Current tech team; 5 software developers, 1 Ultra high vacuum metal deposition specialist, 1 High voltage system designer, a theoretical physisist. We are particularly looking out for experienced electron gun designers (Electron beam welding/accelerator).

It would be great for another team to be set up in another part of the world to inspire each other!

Criteria ; Design a Metal 3D Printer , that produces dimensionally finished parts +- 1µ m , largly self reproducing, electrical supply limited to single phase ( ie not 3 Phase,), minimum consumables beyond metal powder ( avoiding need for e.g.argon gas ... etc,),cost for parts less than a small car, buildrate can be slow i.e. .2KG per hour, no bigger than a wardrobe.

Do get in touch if you want to build a team in your area.

Related Projects

Files and Parts

Sub Assemblies and Related

EBS=Electron beam sinterer/melting.

sequence - electron gun parts repstrapped EBS. Assembled tested in repstrap vacuum chamber. Metal powder deposition mechanism parts repstraped EBS . Gun depoosition assembled tested. MetalicarapVacuumChamber parts Electron beam sintered by our system. MetalicarapVacuumchamber assembled tested. 5 Elements assembled and tested.