MakiBox

Release status: experimental

| Description | Full case 3d printer

|

| License | ???

|

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Introduction

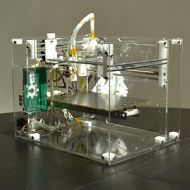

It’s the first 3D printer designed from the ground up to be simple, completely self-contained, reliable and most important of all, affordable!

The MakiBox A6 is a fully enclosed design, allowing for a consistent heated printing (build) space. The motors and electronics are separate from the printing space and have an active cooling fan to draw air past them to keep them cool and working at top efficiency. The printing material fits inside of the MakiBox, so nothing sticks out, keeping things neat and compact.

The MakiBox is designed to be more simple and reliable than any other in this class. Instead of using complicated belts and pulleys, it uses simple drive screws, reducing the number of parts, the cost, and the assembly and maintenance time. We will pre-assemble the most difficult parts, such as the extrusion head or the drive shaft coupling so that the kit assembly is no more difficult than an IKEA furniture.

We are just getting started (2012/07) with both the A6 and other devices that will help people build things they need. The next features we will build for the A6 are multi-color printing and plastic recycling, laser cutting and marking, and PCB routing. These new addons for the A6 will turn it into a desktop manufacturing system, not just a 3D printer.

Specifications

- Printed Parts: ???

- Non-Printed Parts: ???

- Material Cost: ???

- Cost: USD 300 (most assembled)

- Printing Size: 150mm x 120mm x 110mm (6"x4.5"x4.5")

- Precision: 0.04mm (position/printing)

- Speed: 8-10cm/s (position/printing)

- Head: XY

- Bed: Z

Specialities

- Full acryl case (unlike the photo)

- Using pellets, creating filament within (ABS pellets 1/3 cost of filament)

- Threaded rods, no pulleys

Even though the project aims rather to be a self-contained 3d printer than a RepRap (self-replicating 3d printer) some of the features could be re-used and a stripped down version further developed. In particular the pellet to filament part could be interesting to adapt.