FTIStrap

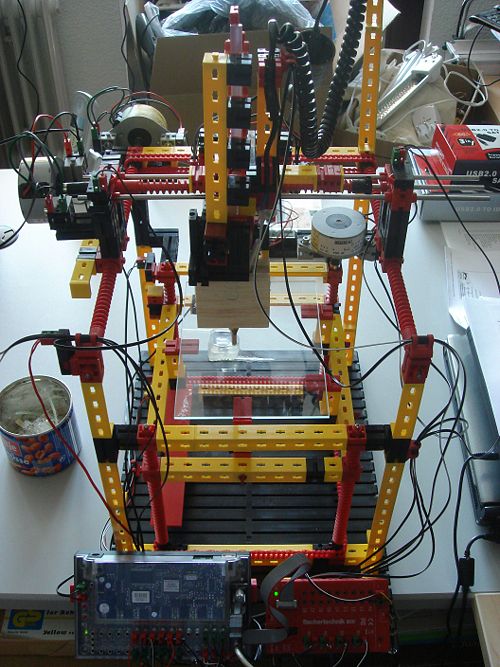

This page describes the "FTIStrap", a RepStrap which is almost completely built from FischerTechnik parts. Constructing an FTIStrap neither needs any special expertise nor any special tools and can usually be completed within a single working day. All parts can either be ordered online or found in many stores in your neighbourhood. After printing the parts for a RepRap the FTIStrap may even be disassembled again and its parts used for other projects.

(please note: because of relatively strict time limits, I plan to document the FTIStrap piece by piece finishing around midth of november)

Contents

Introduction

The FTIStrap is a "RepStrap" which almost completely consists of FischerTechnik parts. Stepper motors are used as actuators, the interior of a hot-melt gun forms the extruder and a (removable) glass plate acts as the base to print on. A FischerTechnik "Robo Interface" together with an extension module (both running in "online mode") controls the steppers and scans the end stops - they can be connected to an IBM-compatible PC running Windows or Linux or an Apple Macintosh running MacOS X. The FTIStrap is completely "host-controlled" - a small application running on the host can be used to either manually operate the machine or load and interpret a file containing the "G codes" for a RepStrap.

The FTIStrap's main "advantages" are

- it almost completely consists of FischerTechnik parts - including steppers and the driver and interface electronics - which can be ordered online

- the few remaining parts (hot-melt gun, balsa wood, sand paper, fan, glass plate) can also either be bought online or found in various shops in your neighbourhood

- no special tools are required to build the FTIStrap - although a hacksaw is recommended to cut the balsa wood which covers the hot-melt gun

- no soldering is required - all the electronics you need is already available from FischerTechnik

- when all parts are available, the whole FTIStrap can be easily assembled within a single working day

- as soon as you no longer need the FTIStrap (because you used it to build your own RepRap), it can be disassembled again and its parts used for other projects

The current printing characteristics are

- position accuracy: approx. 0.1 mm in all directions

- material thickness in xy direction (i.e. line width): approx 1.0 mm

- material layer thickness (z direction): approx 0.5 mm

The hot-melt gun which is currently used needs cylindrical hot-glue sticks with a diameter of 7mm. The gun melts it at a temperature around 230° celsius which is hold by a thermistor within the gun. The rigidity of the printed objects depends on the thickness of their walls (in relation to their sizes, of course): one of the first printed test objects, which accidentially got thicker walls than foreseen, turned out to be really rigid.

Part List

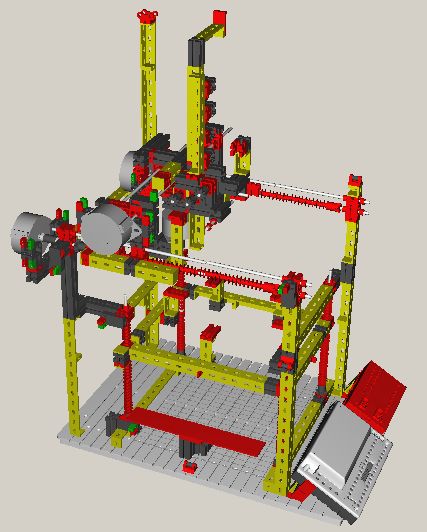

The list of FischerTechnik parts has been automatically generated by the "FischerTechnik Designer" which was used to model the FTIStrap and document its building phases.

(tbd - still waiting for the designer)

Besides the FischerTechnik parts, you will also need

- a Proxxon Mini hot-melt gun (or a similar one if you don't mind modifying the extruder housing and its feed)

- a strip of balsa wood (10mm thick)

- some heat-resistant glue (the author used "Uhu hart" for that purpose)

- a little bit of (rough) sand paper (to cover the cylindrical drives of the hot-glue feeder)

- a glass plate (17.2x12.5 cm*cm, taken from a "frame-less picture frame" which usually costs less than 1€)

- a cheap fan (12x12 cm*cm, 12V)

- some cable straps

- if need be: a USB-to-Serial converter and/or a serial cable

- if need be: a 12V power adapter for the FischerTechnik interfaces and/or the fan (if you do not want to buy the FischerTechnik PowerBlock)

The tools you should have:

- a small screw driver (for the Fischertechnik steppers - you may order them together with the other parts)

- a sharp knife (to carve the balsa wood into shape)

- a frame saw (to cut the balsa wood - if need be, you may use the knife for that purpose, but a saw usually gives better results)

Constructing the Extruder

(tbd)

FTIStrap Assembly

(I've started modelling the FTIStrap with the "FischerTechnik designer". Unfortunately, the "Demo Version" handles up to 10 elements only - this is what you see below - and the "Full Version" is still to be shipped to me...)

(tbd)

Cabling

(tbd)

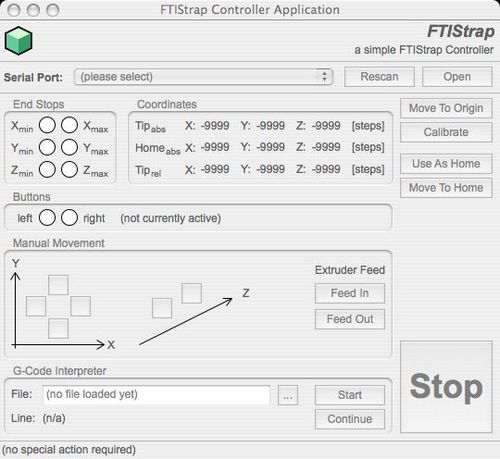

Driver Software

The "FTIStrap Controller Application" provides everything you need. It can be used

- to test and calibrate your set-up

- to move the FTIStrap manually

- to load and evaluate G-Code files

It won't win a price for its user interface but should still be intuitively usable

(tbd)

Initial Startup of the FTIStrap

Check the End Stops

Check the Steppers

Move into the Origin

Calibrate the System

and save the current configuration

Check the Hot-Melt Gun (and the Fan)

(tbd)

You are now ready to start your first print.

Operation Manual

(tbd)

Tips and Tricks

Quite often, people using hot-glue for printing complain that they were unable to remove their objects from the base plate they printed on - the author never had these problems. The possible reason for successful printing might be:

- a glass-plate is used as the base to print on

- just before printing this glass-plate is wiped with a "multi-purpose anti-static" cleaning cloth which is usally used to clean computer monitors, mobile phones and other devices

- after printing, the object may then be vertically detached from the plate (perpendicular to the base layer) - detach with a bit of care, but it usually gets off easily

(tbd)

Material Recycling

3D printers may also have some nice ecological side-effects: you may use them to "repair" broken devices - and you may reuse the material of "mis-prints" and printed parts which are no longer needed.

The author is currently experimenting with an approach to cast his own hot-glue sticks - more to come...

(tbd)

Software Downloads

The "FTIStrap Controller Application" has been developped with REALbasic on an apple Macintosh running MacOS X - but it may also compiled for Windows XP/Vista and Linux x86.

(tbd)

Future Plans

(tbd)