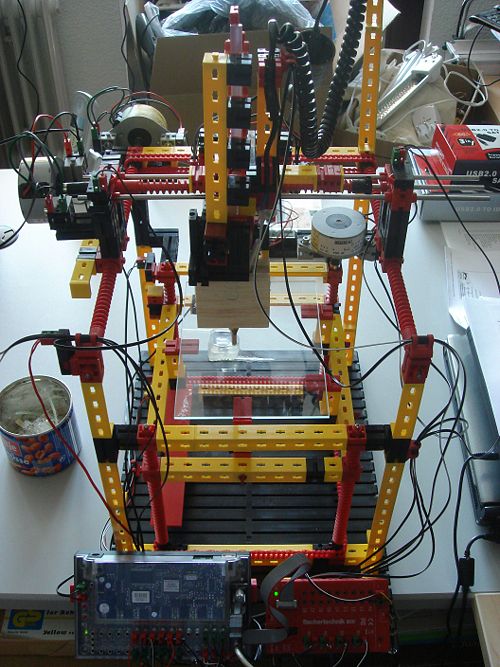

FTIStrap

This page describes the "FTIStrap", a RepStrap which is almost completely built from FischerTechnik parts. Constructing an FTIStrap neither needs any special expertise nor any special tools and can usually be completed within a single working day. All parts can either be ordered online or found in many stores in your neighbourhood. After printing the parts for a RepRap the FTIStrap may even be disassembled again and its parts used for other projects.

(please note: because of relatively strict time limits, I plan to document the FTIStrap piece by piece finishing around midth of november)

Contents

Introduction

The FTIStrap is a "RepStrap" which almost completely consists of FischerTechnik parts. Stepper motors are used as actuators, the interior of a hot-melt gun forms the extruder and a (removable) glass plate acts as the base to print on. A FischerTechnik "Robo Interface" together with an extension module (both running in "online mode") controls the steppers and scans the end stops - they can be connected to an IBM-compatible PC running Windows or Linux or an Apple Macintosh running MacOS X. The FTIStrap is completely "host-controlled" - a small application running on the host can be used to either manually operate the machine or load and interpret a file containing the "G codes" for a RepStrap.

The FTIStrap's main "advantages" are

- it almost completely consists of FischerTechnik parts - including steppers and the driver and interface electronics - which can be ordered online

- the few remaining parts (hot-melt gun, balsa wood, sand paper, fan, glass plate) can also either be bought online or found in various shops in your neighbourhood

- no special tools are required to build the FTIStrap - although a hacksaw is recommended to cut the balsa wood which covers the hot-melt gun

- no soldering is required - all the electronics you need is already available from FischerTechnik

- when all parts are available, the whole FTIStrap can be easily assembled within a single working day

- as soon as you no longer need the FTIStrap (because you used it to build your own RepRap), it can be disassembled again and its parts used for other projects

The current printing characteristics are

- position accuracy: approx. 0.1 mm in all directions

- material thickness in xy direction (i.e. line width): approx 1.0 mm

- material layer thickness (z direction): approx 0.5 mm

The hot-melt gun which is currently used needs cylindrical hot-glue sticks with a diameter of 7mm. The gun melts it at a temperature around 230° celsius which is hold by a thermistor within the gun. The rigidity of the printed objects depends on the thickness of their walls (in relation to their sizes, of course): one of the first printed test objects, which accidentially got thicker walls than foreseen, turned out to be really rigid.