FTIStrap

This page describes the "FTIStrap", a RepStrap [1,2] which is almost completely built from fischertechnik [3] parts. Constructing an FTIStrap neither needs any special expertise nor any special tools and can usually be completed within a single working day. All parts can either be ordered online or found in many stores in your neighbourhood. After printing the parts for a RepRap the FTIStrap may even be disassembled again and its parts used for other projects.

(please note: today, I am trying to complete the assembly instructions - the software should then be ready by tomorrow - provided, that my son does not become sicker than he already is...)

Another note: it is done - the "didacta 2009" fair in Hannover is over! More than 400 visitors came to my booth in order to see the FTIStrap in action and learn about the underlying technology. And quite a few of them announced their intention to build a copy of this 3D printer - now, I am curious to see how many copies will actually be built in the next few months!

By the way: the FTIStrap is also up to be elected as the "fischertechnik model of the period January to March 2009" (see http://www.fischertechnik.de, under "Fanclub" -> "Gallery", you don't have to be a member of the Fischertechnik Fan Club in order to be able to vote) - Vote for me!

Contents

- 1 Introduction

- 2 Part List

- 3 Extruder Construction

- 4 FTIStrap Assembly

- 5 Cabling

- 6 Driver Software

- 7 Initial Startup of the FTIStrap

- 8 Operation Manual

- 9 Tips and Tricks

- 10 Material Recycling

- 11 Software Downloads

- 12 Modifications and Extensions

- 13 Events

- 14 Future Plans

- 15 Configuration File Format

- 16 References

Introduction

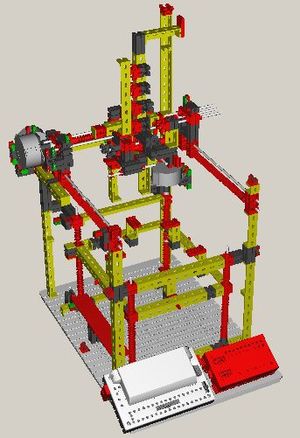

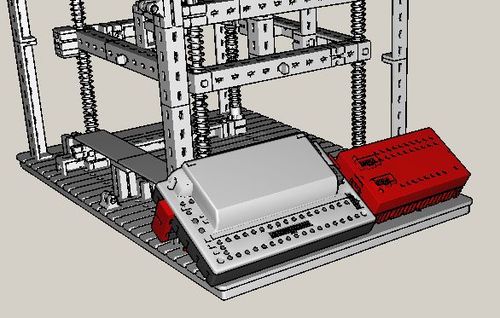

The FTIStrap is a "RepStrap" which almost completely consists of fischertechnik parts. Stepper motors are used as actuators, the interior of a hot-melt gun forms the extruder and a (removable) glass plate acts as the base to print on. A fischertechnik "Robo Interface" together with an extension module (both running in "online mode") control the steppers and scan the end stops - they can be connected to an IBM-compatible PC running Windows or Linux or an Apple Macintosh running MacOS X. The FTIStrap is completely "host-controlled" - a small application running on the host can be used to either manually operate the machine or load and interpret a file containing the "G codes" for a RepStrap.

The FTIStrap's main "advantages" are

- it almost completely consists of fischertechnik parts - including the four steppers and any electronics - and everything can be ordered online [4]

- the few remaining parts (hot-melt gun, balsa wood, sand paper, glue, fan, glass plate) can also either be bought online or found in various shops in your neighbourhood

- no special tools are required to build the FTIStrap - although a hacksaw is recommended to cut the balsa wood which covers the hot-melt gun

- no soldering is required - all the electronics you need is already available from fischertechnik

- when all parts are available, the whole FTIStrap can be easily assembled within a single working day

- as soon as you no longer need the FTIStrap (because you used it to build your own RepRap), it can be disassembled again and its parts used for other projects

The current printing characteristics are

- position accuracy: approx. 0.1 mm in all directions (i.e., approx 256 lpi)

- material thickness in xy direction (i.e. line width): approx 1.0 mm

- material layer thickness (z direction): approx 0.5 mm

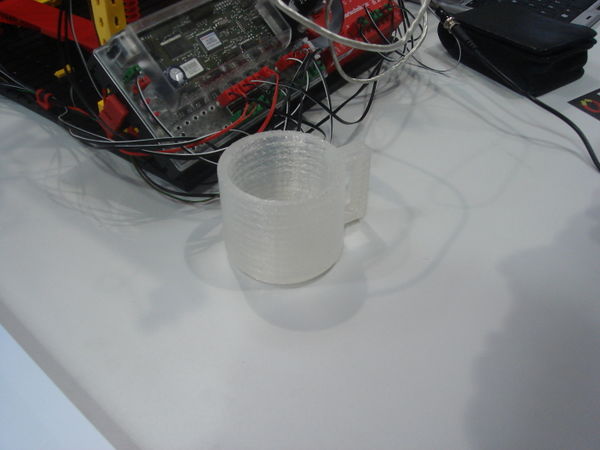

The hot-melt gun which is currently used needs cylindrical hot-glue sticks with a diameter of 7mm. The gun melts them at a temperature of approx. 230° celsius which is hold by a thermistor within the gun. The rigidity of the printed objects depends on the thickness of their walls (in relation to their size, of course): one of the first printed test objects, which accidentially got thicker than foreseen, turned out to be really rigid.

Warning!

If you plan to build your own copy of the FTIStrap, play around with it and/or show it to other people, please read the following paragraph carefully:

- the hot-melt gun operates with 220V and - although the cabling seems to be professionally insulated (see the pictures below) - handling close to the cables might be dangerous!

- the hot-melt gun operates at approx. 230° Celsius - do not touch the nozzle, it's hot!

- should you have damaged the insulation between the heating element of the hot-melt gun and its metallic parts, the nozzle is not only hot but also connected to 220V power!

Thus: never let the FTIStrap operate unattended - especially if visitors are near. Keep it away from young children! Before presenting your machine to others, tell your visitors that they must not touch the machine - under no circumstances!

The author must never be held liable for any damages or injuries caused by your own copy of the FTIStrap - use it at your own risk!

Part List

Originally, the list of fischertechnik parts has been automatically generated by the "fischertechnik designer" [5] which was used to model the FTIStrap and document its building phases. It has then been extended by the author (e.g., to include the chain elements) and modified (to be able to order "bags" with many parts rather than having to order every kind of item individually).

You will need the following items (the english part names are the author's (probably naive) translations from their german counterparts - if you have the "official" names, do not hesitate to fill them in here. Nevertheless, the part numbers should help you identifying the proper items)

- 1 x 35602 base plate 390x270 (Grundplatte 390x270)

- 16 x 36294 angle bracket 120,yellow (Winkelträger 120, gelb)

- 14 x 36297 angle bracket 60, yellow (Winkelträger 60, gelb)

- 19 x 36299 angle bracket 30, yellow (Winkelträger 30, gelb)

- 6 x 35053 angle bracket 15, yellow (Winkelträger 15, gelb)

- 5 x 35076 static brick (Statikstein, gelb)

- 9 x 32850 bar brick 15x15 (Riegelstein 15x15)

- 5 x 36323 s bar 4 red (S-Riegel 4 rot)

- 36 x 32064 brick 15 with hole (Baustein 15 mit Bohrung)

- 12 x 32879 brick 30, black (Baustein 30 schwarz)

- 30 x 32881 brick 15, black (Baustein 15 schwarz)

- 10 x 32882 brick 15 with two plugs (Baustein 15 mit zwei Zapfen)

- 4 x 31011 angle brick 30 degrees (Winkelstein 30 Grad)

- 3 x 37328 brick 5 with two plugs (Baustein 5 mit 2 Zapfen)

- 26 x 37237 brick 5 (Baustein 5)

- 15 x 35049 brick 15x30x5 with slot and plug (Baustein 15x30x5 mit Nut und Zapfen)

- 14 x 37468 brick 7.5 (Baustein 7.5)

- 26 x 31982 flute pin (Federnocken)

- 1 x 31061 connector 30 (Verbindungsstück 30)

- 8 x 31060 connector 15 (Verbindungsstück 15)

- 19 x 38236 plate 15x15, yellow (Bauplatte 15x15, gelb)

- 2 x 38251 plate 30x90, red (Bauplatte 30x90, rot)

- 2 x 38428 plate 15x30x5 with three slots (Bauplatte 15x30x5 mit 3 Nuten)

- 1 x 31034 metal rod 30 (Metallachse 30)

- 2 x 37384 metal rod 80 (Metallachse 80)

- 2 x 31031 metal rod 110 (Metallachse 110)

- 4 x 35697 metal rod 200 (Metallachse 200)

- 33 x 37679 clamping bush 5 (Klemmbuchse 5)

- 9 x 35112 bevel Z10, M1.5 (Ritzel Z10, M1.5)

- 8 x 31915 screw nut (Zangenmutter)

- 6 x 35113 tongs (Spannzange)

- 11 x 37858 clampable worm m=1.5 (Klemmbare Schnecke m=1.5)

- 32 x 37926 worm element m=1.5 (Schneckenteil m=1.5)

- 9 x 37925 worm nut m=1.5 (Schneckenmutter m=1.5)

- 2 x 35695 gear Z15 (Zahnrad Z15)

- 2 x 32649 bag of chain links (Rastkettenglied Beutel)

- 1 x 37636 roller bearing (Rollenlager)

- 5 x 32085 roller bracket (Rollenbock)

- 4 x 31436 hinge claw (Gelenkwürfel-Klaue)

- 4 x 36819 bearing sleeve (Lagerhülse)

- 6 x 37783 mini switch (Mini-Taster)

- 30 x 31336 contact pin, green (Flachstecker, grün)

- 30 x 31337 contact pin, red (Flachstecker, rot)

- 4 x 32311 Stepper Motors

- 4 x 75045 bag with parts for a stepper motor (Teilebeutel für Schrittmotor)

- 1 x 93293 Robo Interface

- 1 x 93294 Robo IO-Extension

- 1 x 79015 stepper motor hints (Hinweise zum Schrittmotor) just for your information, not really necessary

It seems as if some of the axes the author used for constructing the FTIstrap are no longer available - you will have to get them from other sources. The following axes are needed:

- 4 x axes 300mm (4mm diameter)

- 3 x axes 250mm (4mm diameter)

It should not be too difficult to cut metal rods of an appropriate diameter to the proper length. Steel rods would be the best choice, but brass might be easier to cut.

Besides the fischertechnik parts, you will also need

- a Proxxon hot-melt gun (Proxxon no. 28192, or a similar one if you don't mind modifying the extruder casing and its feeder)

- a strip of balsa wood (10mm thick)

- some heat-resistant glue (the author used "Uhu hart" for that purpose)

- a little bit of (rough) sand paper (to cover the cylindrical drives of the hot-glue feeder)

- a glass plate (17.2x12.5 cm*cm, taken from a "frame-less picture frame" which usually costs less than 1€)

- a cheap fan (12x12 cm*cm, 12V)

- some cable straps

- some silicon oil (to reduce friction along the plastic thread rods)

- if need be: a USB-to-Serial converter and/or a serial cable

- if need be: a 9V power adapter for the fischertechnik interfaces (if you do not want to buy the fischertechnik PowerBlock)

- if need be: a 12V power adapter for the fan

and, of course, you will need

- hot glue sticks (e.g., Proxxon no. 28194, or similar - depending on your actual hot-melt gun)

The tools you should have:

- a small screw driver (for the fischertechnik steppers - you may order them together with the other parts)

- a sharp knife (to carve the balsa wood into shape)

- a frame saw (to cut the balsa wood - if need be, you may use the knife for that purpose, but a saw usually gives better results)

Extruder Construction

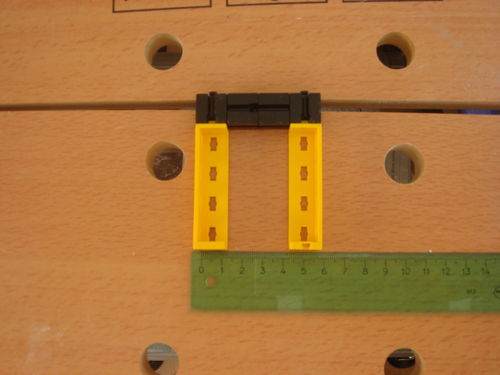

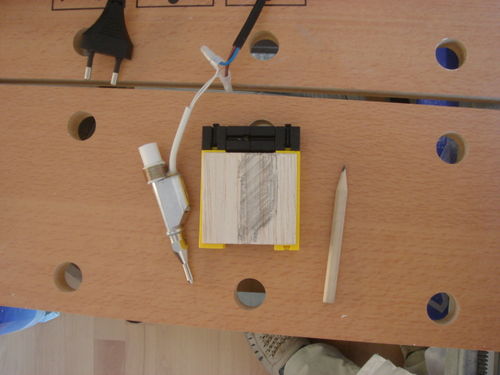

The extruder consists of nothing but (the interior of) a conventional hot-melt gun which was enclosed by layers of balsa wood and fixed within two fischertechnik parts (part no. 36297 or similar)

This is the Proxxon hot-melt gun (Proxxon no. 28192) which was actually used - if you prefer another one, you may have to modify the balsa wood casing (and probably the feeder as well).

If you open the casing, you will see its inner parts:

Just take the heater element and remove everything else. Important: do NOT cut-off the silicon guide for the hot-glue sticks (as the author did on this picture) it is really important for the proper functioning of the gun! The author's first gun turned out to be completely useless and he had to buy a second one to proceed! The feeder is now by far strong enough to shift the sticks through the guide into the heater element.

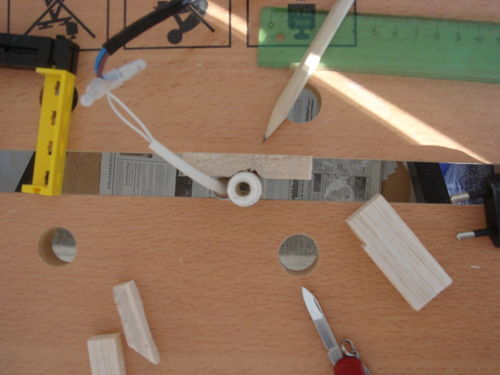

The following picture shows all the parts you need to build the balsa wood cabinet for the hot-melt gun (well, almost all parts: the author forgot the heat-resistant glue that is needed to glue all parts together. You will see it later in the process).

The hacksaw is used to cut the balsa wood into parts which are then carved into their proper (irregular) shape using a pocket knife.

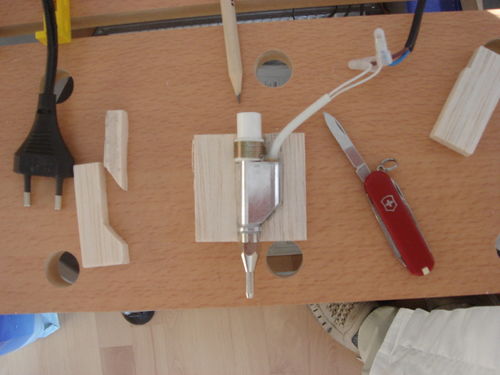

In order to get the proper size of the cabinet, you should assemble the following "bracket" and test, if your balsa wood parts fit into that bracket. Although the final mount will look different, this bracket will help while you cut the parts.

Take your balsa wood stripe (which must be 10mm strong) and cut a block of 52x56 mm^2 in size. Test if it fits.

Place the heating element on the balsa block and move it until both the inlet and the nozzle are horizontally centered. If you look at your heating element, you will recognize a thin ring just beneath the wide body: this ring should be placed as far away from the lower end of the cabinet as possible - during operation, this ring helps keeping the heating element firmly in its cabinet.

As soon as you have placed the heating element at its proper place you shoud press the ring into the balsa wood. This will produce a small cavity which may then be carved a little bit deeper with a pocket knife.

You may now mark the area covered by the heating element. It may later help you when you will have to carve a cavity for the filament.

Cut another balsa block of the same size (52x56 mm^2) and place the heating element on it as before - but do not forget to turn it around first! Again, press the ring into the balsa wood and carve it a little bit deeper.

You may mark the area covered by the heating element again:

Fortunately, the heating element is also approx. 10 mm strong - only the filament and the abovementioned ring need more space. For that reason, it is quite easy to produce the inner parts of the cabinet: just cut (and carve) some more balsa wood parts into shape - the marked areas will help you finding the required size for these parts!

Check if the part fits to the heating element.

The second (inner) part has slightly more complicated shape - thus, it's a good idea to mark the areas first, which are going be removed, before actually doing so.

Carve the part into shape and check if it fits.

As mentioned above, the filament is larger than 10mm. For that reason, it is necessary to carve a small cavity into the outer balsa wood parts. The following picture illustrates how the result will look like (from above, look where the tip of the pencil points to):

The next picture shows the cavity from the side (the tip of the pencil points at it). Please, also note the small cavity for the ring that was mentioned before: in the picture it is the small area which has been marked with the pencil and therefore looks a bit darker than the rest of the marked area.

Always check if all parts fit.

Carve two more cavities (for the filament and the ring) into the other (outer) balsa block.

As soon as all parts fit nicely, you may start glueing the inner parts onto one of the outer ones. Place the heating element within the inner parts - it will help you moving all parts into their proper positions.

You do not have to wait now - just glue the last balsa part onto the others and clamp the whole cabinet (with the heating element inside!) together until the glue has hardened.

In a final step you may sand and/or carve the edges of the cabinet in order to look nicely - but there is no real need to do so.

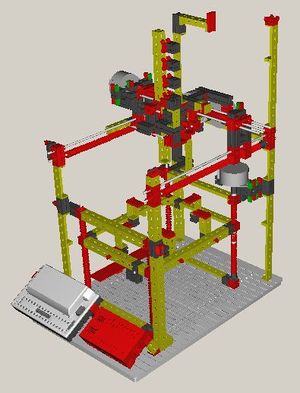

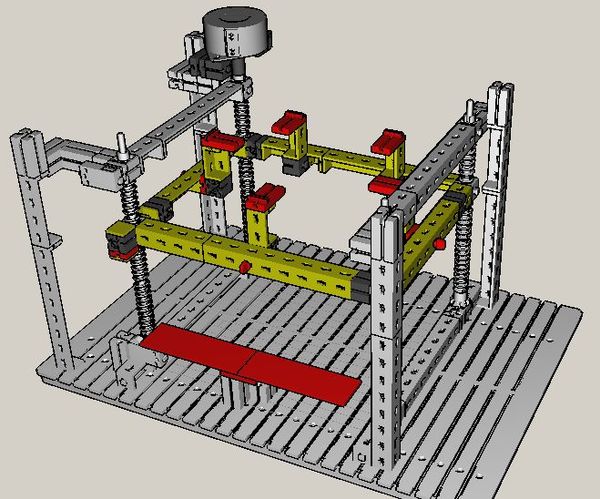

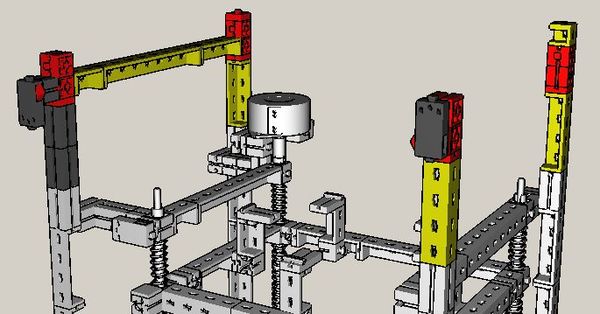

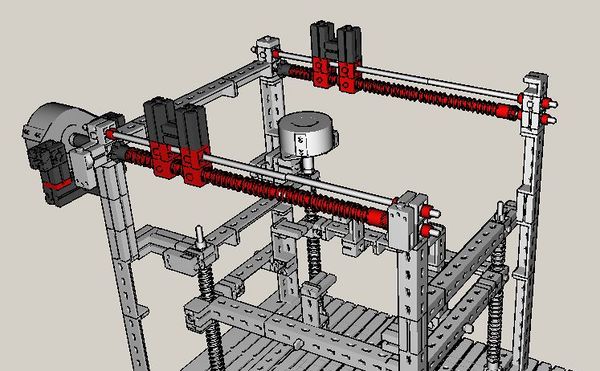

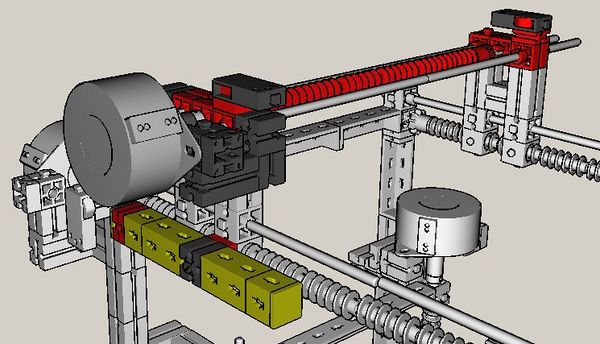

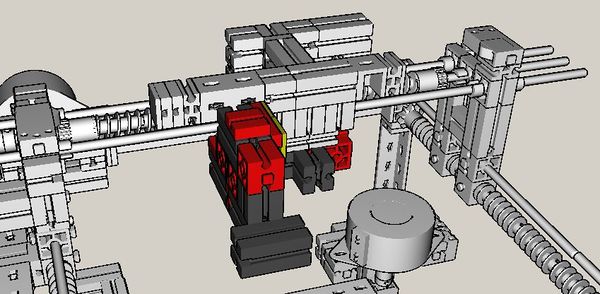

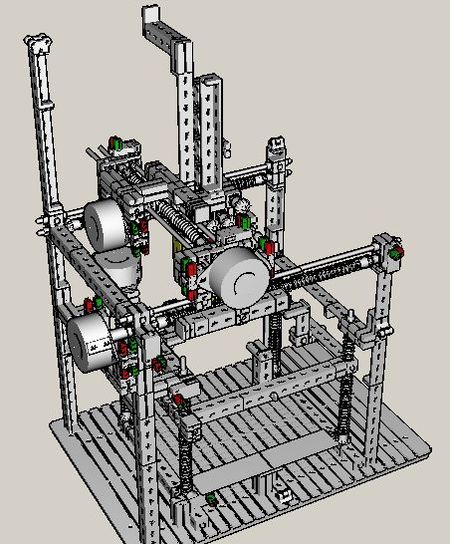

FTIStrap Assembly

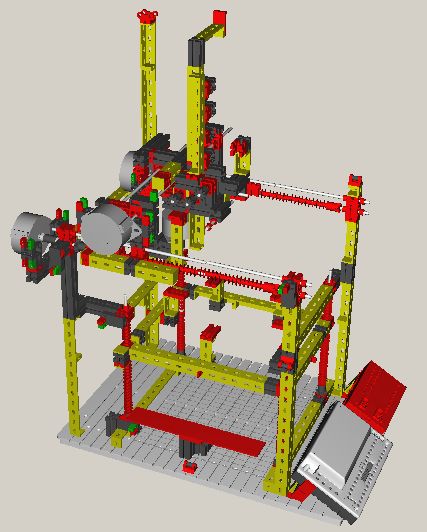

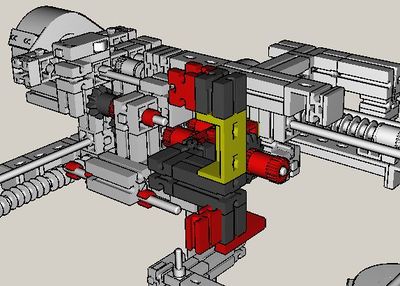

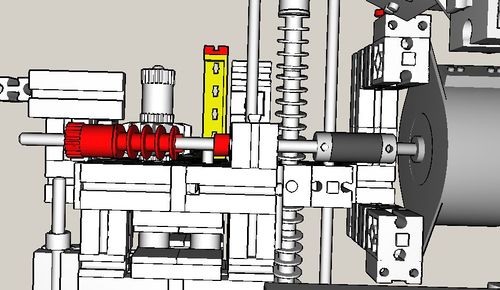

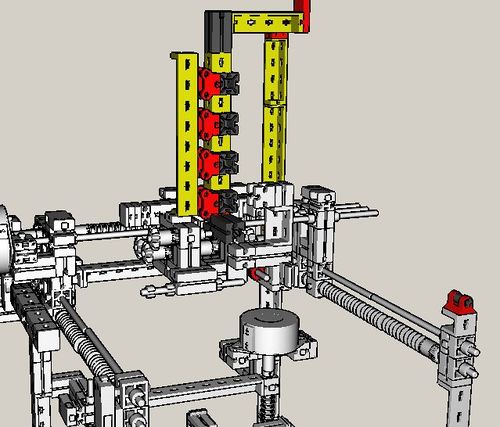

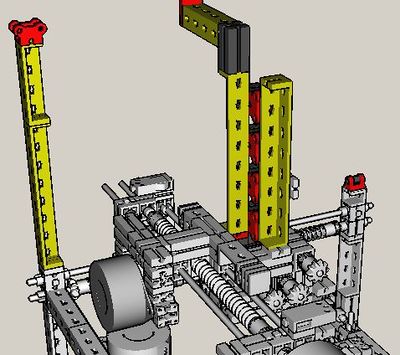

The author has used the "fischertechnik designer" [5] to create a model of the FTIStrap. This model was the basis for the following illustrations of the assembly process. These illustrations will hopefully help you constructing your own copy of the FTIStrap - if anything remains unclear, don't hesitate to ask the author for clarification.

The underlying model (FTIStrap.ftm) is also available for download: just right-click on the link and select "Save As.." in order to save the file on your local hard disk. You will need the latest version of the "fischertechnik designer" to open this file - you might need the full version as the demo version can only handle up to ten fischertechnik parts.

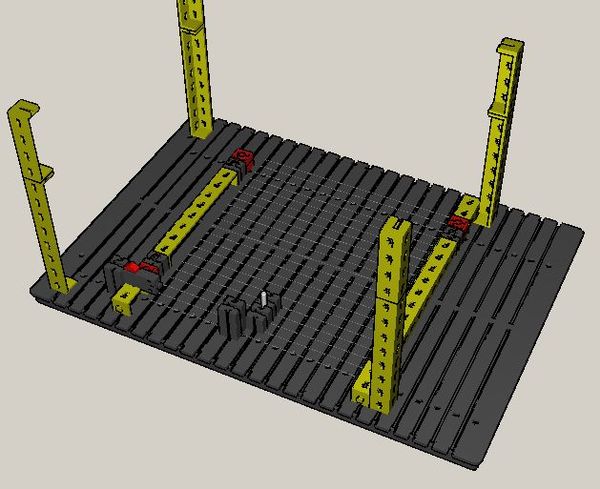

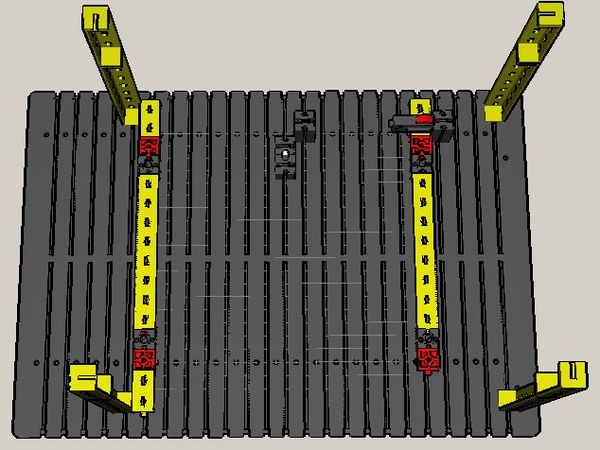

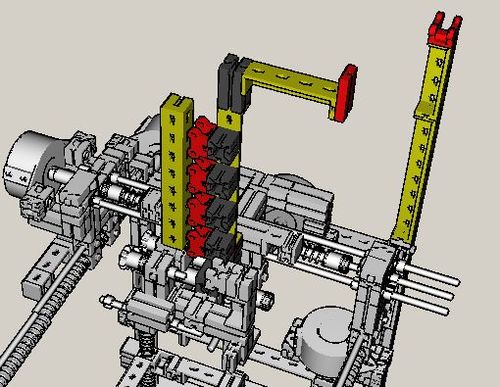

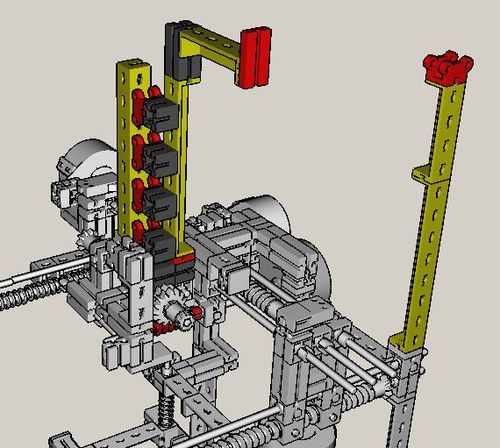

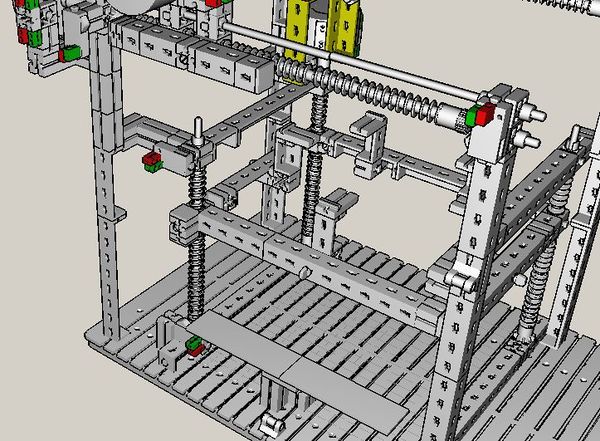

Phase 1

Let's start with the first parts of the outer frame and the base of the z axis lifter.

The part in the middle of the base plate (the one with the metal rod) will later be used to tighten the chain for the z axis lifter. The parts can be moved along the slot in the base plate, the second brick is just used to increase the friction and keep the brick with the rod in place.

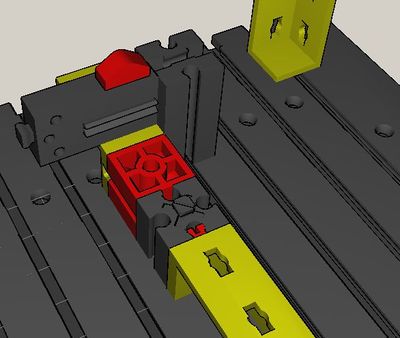

The following detail view will help you assembling the region around the switch (and the other corners, which look very similar). The switch will later act as the lower z axis end stop.

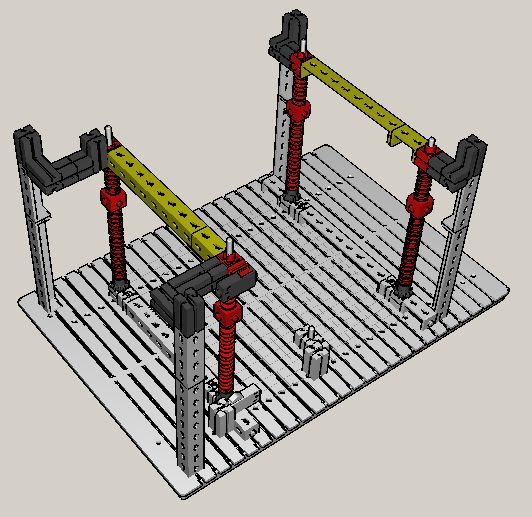

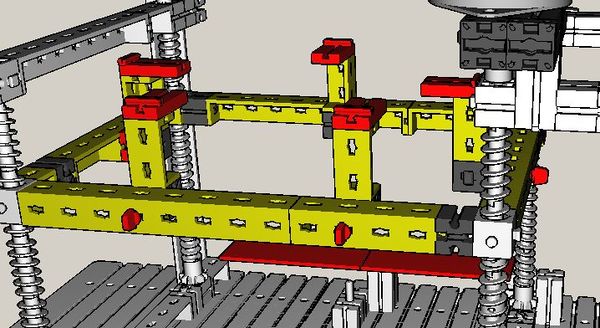

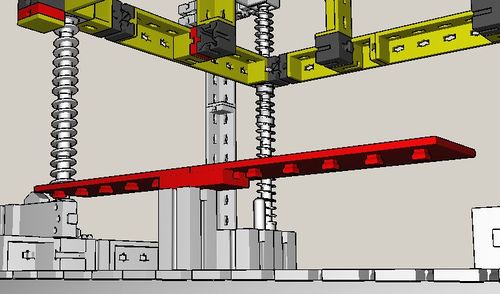

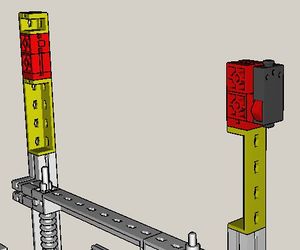

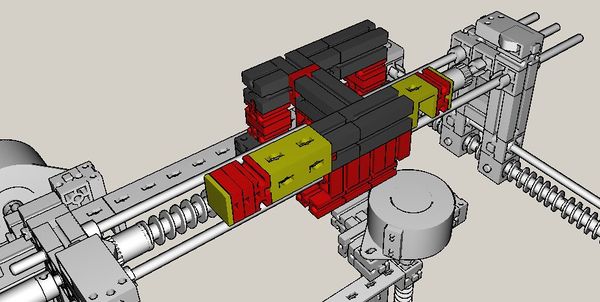

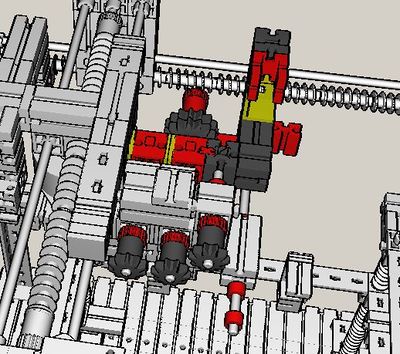

Phase 2

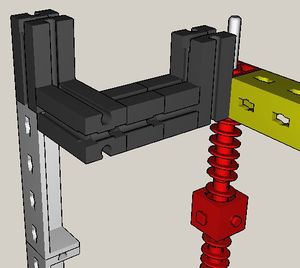

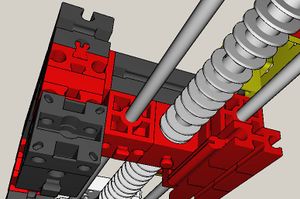

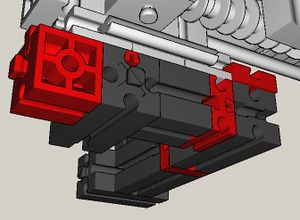

The second phase completes the frame for the z axis lifter: the rods (200 mm long) stick loosely in the lower holed bricks (part no. 36), initially held by their weight, later fixed by upper holed bricks.

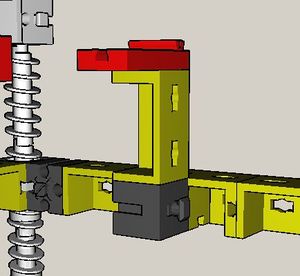

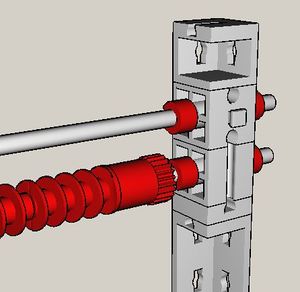

Start (from the bottom) with a clamping bush, a bevel (part no. 35112) and a clampable worm (part no. 37858), then add normal worm elements (part no. 37858). The clamping bush will lift the bevel a bit, thus preventing the chain around all four "thread rods" from sliding over the other fischertechnik parts.

The topmost element of every worm gear is a "normal" worm element (part no. 37858), all elements are fixed in place by the upper holed bricks and a clamping bush (above the brick).

The black bricks are used to fix the rods in x/y-direction:

Do not forget to screw in the worm nuts before you mount the upper holed bricks or you will have to disassemble the frame again.

As soon as the second phase has been completed, you should span a chain around the black gears at the bottom of every rod - and around the small rod in the middle of the plate. Do it in a way which allows you to tighten the chain by moving the bricks with the rod along the slot in the base late. Move them inwards to tighten the chain, and outwards to loosen it again.

Do not tighten the chain too much: it should still run smoothly.

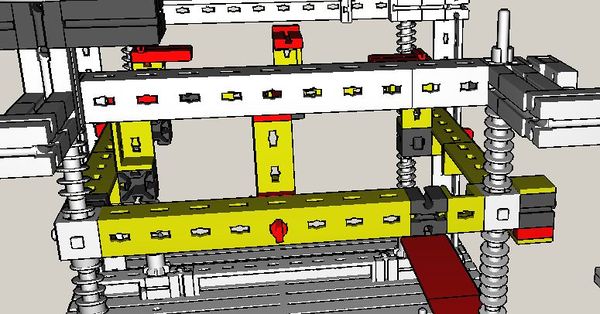

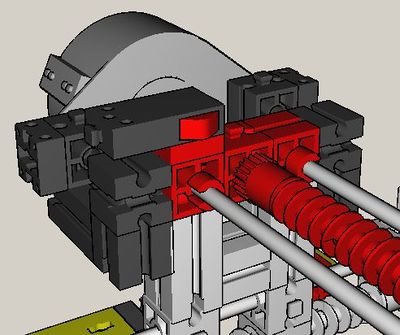

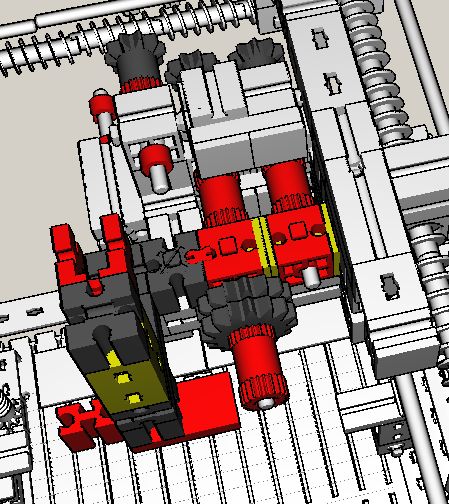

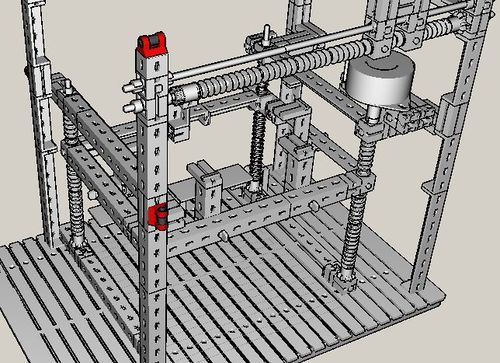

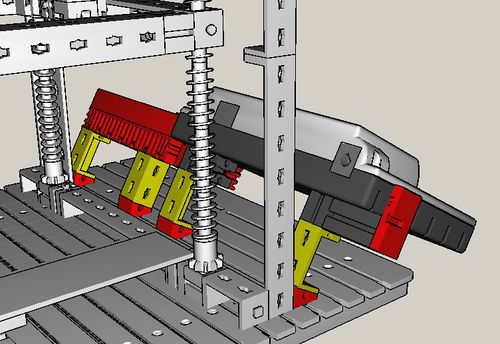

Phase 3

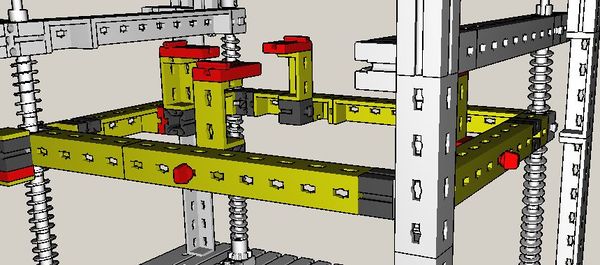

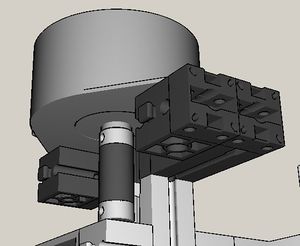

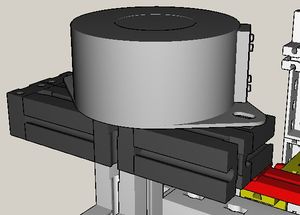

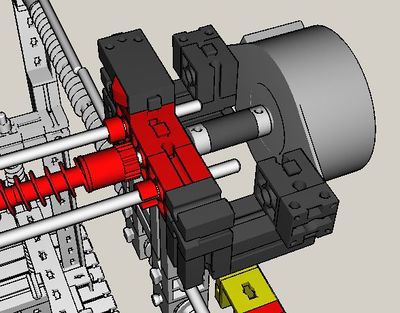

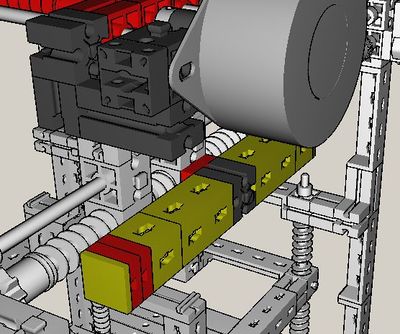

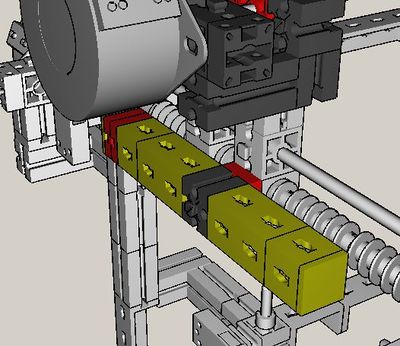

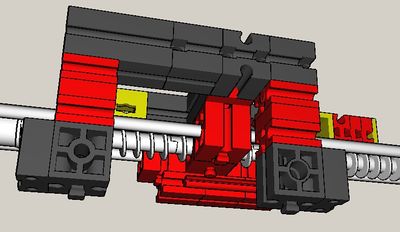

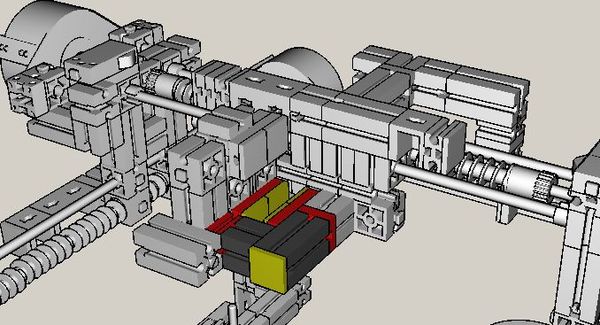

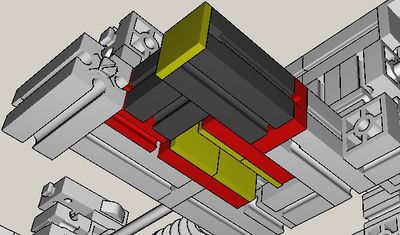

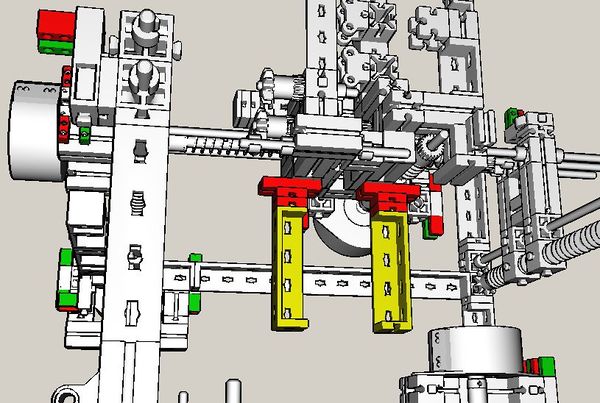

During the third phase, z axis lift and z stepper are assembled.

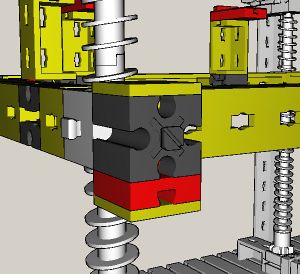

Detail views from every side illustrate how to construct the z axis lift. Make sure, that all worm nuts are on the same level before connecting them through the frame - you might have to loosen the chain a bit in order to turn each worm gear individually. In the end, the lift frame and the x- and y-axes (which will be constructed soon) should be exactly parallel.

The glass plate which forms the basis for the hot glue printouts is loosely placed on-top of five elements which are mounted around the z lift frame - the following detail view shows how to assemble them.

Later, after the initial setup, a test print will show, how precise the base plate has been positioned - and you will have to compensate any deviations with thin paper sheets and/or adhesive tape on the red "brick 15x30x5 with slot and plug" (part no. 35049).

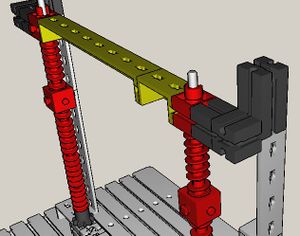

The following image shows the stamps which press the z axis end stops. Shown is a suggestion by the author - depending on your actual construction you might have to vary the assembly slightly.

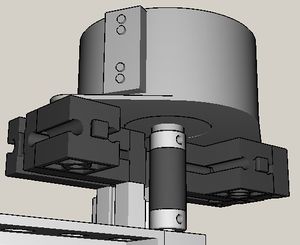

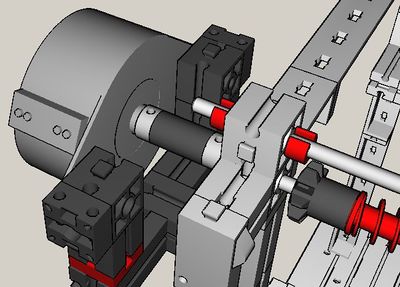

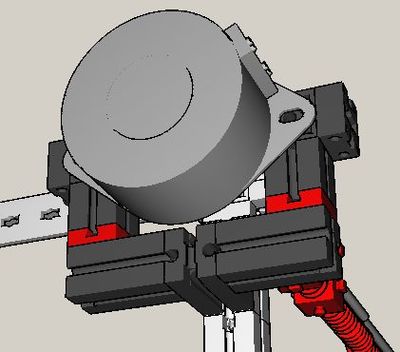

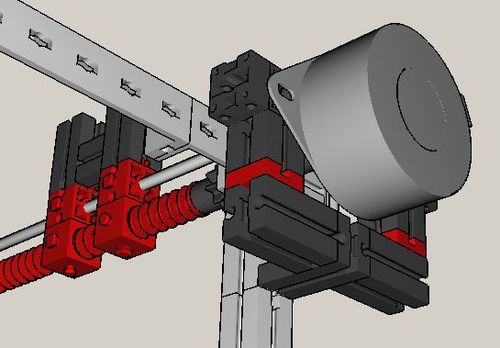

It is time to mount the z axis stepper, the following images show you how. If you do not know how to handle stepper motors, you might look into part no. 79015 (hints for the stepper motor)

You should now also assemble the cover which protects the chain from drops of hot glue (the origin of the FTIStrap is in the corner with the z axis end stops).

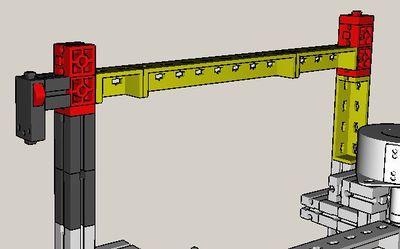

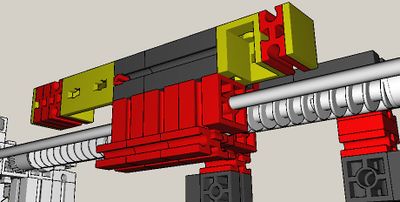

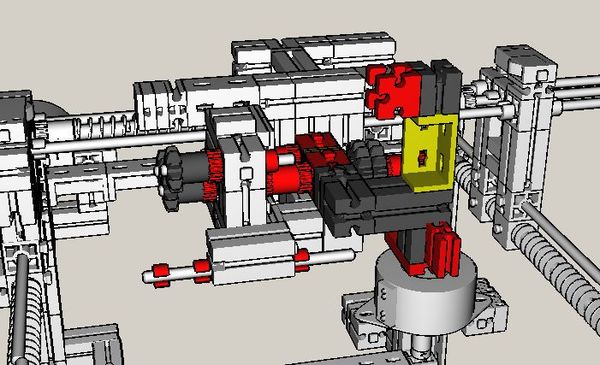

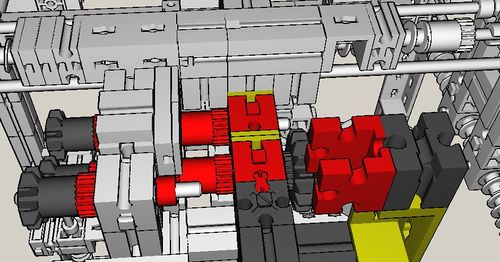

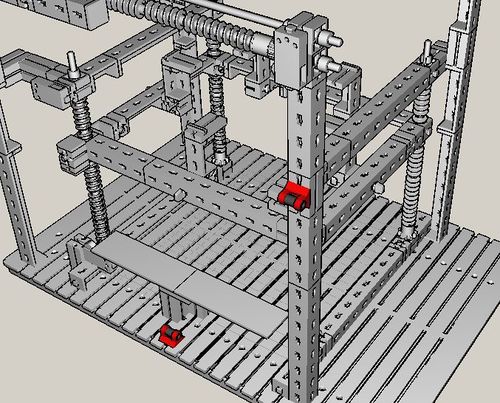

Phase 4

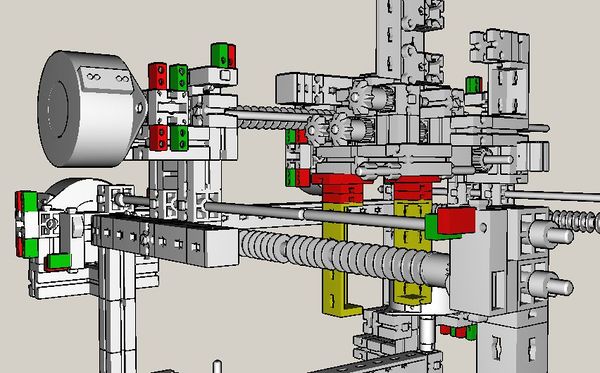

Step four extends the outer frame and prepares it for the x axis rods.

Two rods will be required on each side to carry the weight of the y axis mechanics, the extruder and the extruder feed - a single rod would bend too much.

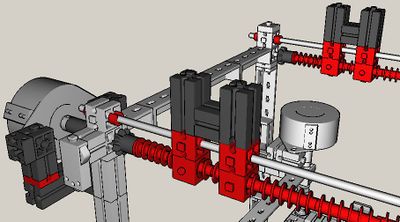

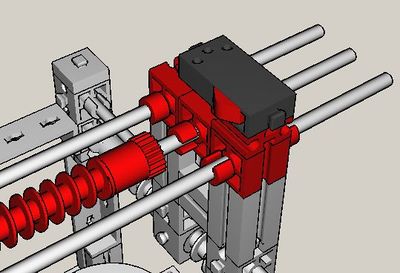

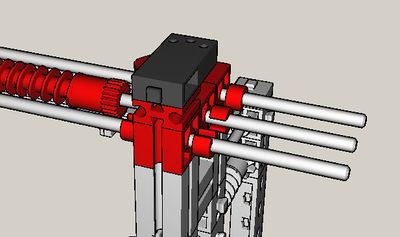

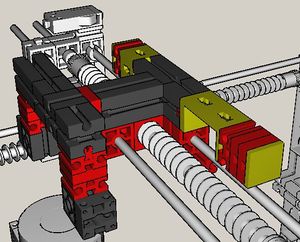

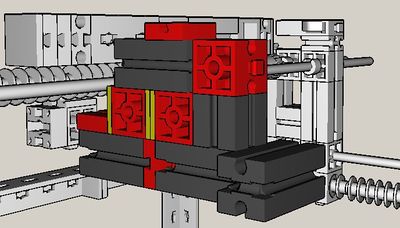

Phase 5

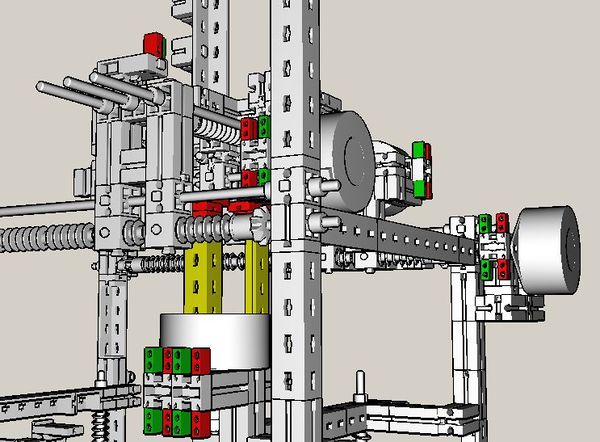

The fifth step adds the x axis mechanics and the beginning of the x axis slider. Clamping bushes at each end of a rod and on both sides of a brick prevent the rod from sliding back and forth.

The rod end at the stepper is the only end where no clamping bushes are needed.

After assembling the x axis mechanics you should manually check that everything runs smoothly.

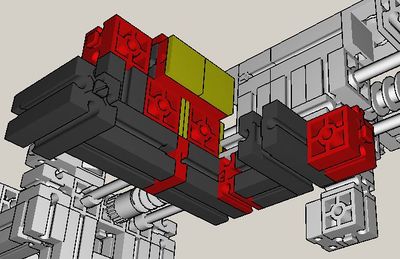

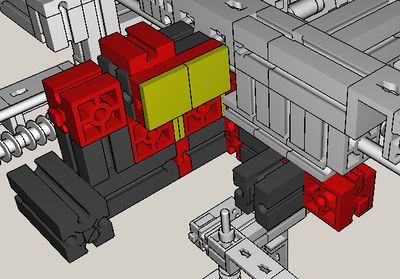

Phase 6

This step illustrates how to construct the y axis mechanics and the stamps for the x axis end stops.

Phase 7

Phase 8

Phase 9

Phase 10

Phase 11

Phase 12

Phase 13

(tbd)

Cabling

(tbd)

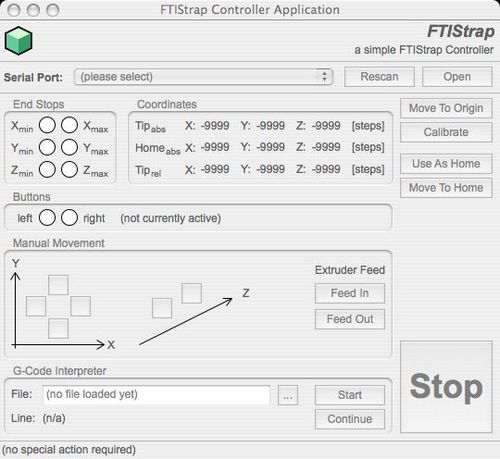

Driver Software

The "FTIStrap Controller Application" provides everything you need. It can be used

- to test and calibrate your set-up

- to move the FTIStrap manually

- to load and evaluate G-Code files

It won't get an award for its user interface but should still be intuitively usable

(tbd)

Initial Startup of the FTIStrap

If you have not done so, start the "FTIStrap Controller Application" - it will be used to test and calibrate your set-up.

Check the End Stops

First of all, you should check the proper operation of your end stops - this includes a test of (a part of) your cabling and the proper communication between your PC and the FischerTechnik interface.

(tbd)

Check the Steppers

Now, you are ready to test the proper operation of any steppers - this includes a test of the remaining part of your cabling.

But before, make sure, that none of the end stops is touched by any part of your machine - it is important that the steppers can run free for a few centimeters, at least. Also, do not "load" the feeder with hot-glue sticks yet.

(tbd)

Move into the Origin

Let the driver now move the system into the "origin" (i.e., the smallest possible x-y-z coordinate) Do not forget to place the glass-plate at its foreseen position in the FTIStrap before.

(tbd)

Check easy Movement along all Axes

Using Fischertechnik parts for constructing a 3D printer is not really a professional approach. Thus, it is very likely, that your thread rods are not exactly parallel. Additionally, the plastic parts suffer from more friction than metallic parts would.

For that reason, you should first check for easy movement along all axes and, if need be, align all rods and reduce friction by means of a little bit of silicon oil.

(tbd)

Calibrate the System

and save the current configuration

Check the Hot-Melt Gun (and the Fan)

It is now time to heat up the hot-melt gun and fill it with glue for the first time.

Thus, energize the heating element and wait a few minutes. In the mean time, you may slide a first glue stick into the feeder and - using the Controller Application - move it down until it reaches the silicon guide.

As soon as the heater has reached its target temperature, move the stick down fast for another two centimetres and then slowly further. Watch the casing while doing so and stop as soon as the casing seems to bend away due to the pressure of the feeder - in that case, just wait until the casing bends back and continue. Sooner or later you should see the first drop of hot glue being pressed through the gun's nozzle.

Now, the heater element has been successfully filled with hot-glue.

You should now also check the fan - just to be sure it works.

Check the Base Alignment

It is very likely, that your glass plate is no exactly parallel to the x-y axes. This is checked by printing a large (but thin) grid over the whole glass plate. From the results of that print you get information about where to lift the plate (e.g. by means of one or several layers of adhesive tape) and whether glass plate and rods are straight enough (or whether they bend because the extruder and its feeder are too heavy)

(tbd)

You are now ready to start your first print.

Operation Manual

(tbd)

Tips and Tricks

Quite often, people using hot-glue for printing complain that they were unable to remove their objects from the base plate they printed on - the author never had these problems. The possible reason for successful printing might be:

- a glass-plate is used as the base to print on

- just before printing this glass-plate is wiped with a "multi-purpose anti-static" cleaning cloth which is usally used to clean computer monitors, mobile phones and other devices

- after printing, the object may then be vertically detached from the plate (perpendicular to the base layer) - detach with a bit of care, but it usually gets off easily

(tbd)

Material Recycling

3D printers may also have some nice ecological side-effects: you may use them to "repair" broken devices - and you may reuse the material of failed prints and printed parts which are no longer needed.

The author is currently experimenting with an approach to cast his own hot-glue sticks - more to come soon...

(tbd)

Software Downloads

The "FTIStrap Controller Application" has been developed with REALbasic on an Apple Macintosh running MacOS X - but it may also be compiled for Windows XP/Vista and Linux x86.

(tbd)

Modifications and Extensions

The current design is far from being perfect and was often motivated by the parts the author had at home while constructing the system. However, one of the most important advantages of using FischerTechnik was (and is) the ease with which new variants can be built and tested - sometimes, it takes only minutes to realize an idea and see how it works.

For that reason, the FTIStrap is the ideal platform for testing alternatives. Among the supposable modifications and extensions are:

- enhancing the stability of the whole construction

- the integration of different extruders

- provisions for two (or even more) extruders

- any kind of approach to handle overhangs

Additionally, it is quite straightforward to

- control the heating element and/or the fan by the host

Enhancing the Stability of the Construction

Currently, the FTIStrap is built from plastic parts only - an approach which works reasonably well (especially, as the driver software takes care of many shortcomings such as friction and vibrations).

On the other hand, FischerTechnik also offers aluminium bricks which are more rigid than other parts (not only because of the material but also because they combine several connected bricks into a single, longer one). If you just replace plastic components by aluminium bricks (where possible) you will enhance the stability of the construction and reduce vibrations during the print.

As a consequence, you might be able to speed up printing (by modifiying the relevant parameters) or apply other modifications (see below) which require an enhanced stability.

Integration of different Extruders

At the moment, the design of the FTIStrap does not foresee an exchange of the extruder - extruder, feeder and y-axis slider are tightly connected to each other. The installation of another extruder would first require the disassembly of the current one - and then you might even have to modify the slider before mounting a new extruder.

On the other hand, it should not be too difficult to modify the design such that the extruder could be replaced without too much effort. Just take care that the modified construction does not become too heavy for the x-axis thread rods or you will have to modify them as well (e.g., by integration of aluminium bricks instead of plastic parts, see above)

It might be an interesting challenge to integrate the "standard" RepRap extruders into the FTIStrap frame - these are far more advanced than a simple "hot-melt gun". Or to integrate one of the syringe-based extruders preferred by the Fab@Home project. Just keep an eye on the overall weight of your construction when you try to use a different extruder.

Provisions for two or more Extruders

Mainly because of the size of the FischerTechnik base plate, the effective printing space of an FTIStrap is smaller than that of a RepRap (or of many other RepStraps). It would therefore be rather difficult to integrate more than a single extruder without reducing the printing space even further.

Overhang Handling

Without additional provisions, an extruder-based 3D printer is unable to print arbitrary overhangs - additionally, all printed objects have to start either on the base plate or (unlikely) on another object. The "Darwin" RepRap design tries to overcome this deficiency by means of another extruder which prints an (easily removable) "filler" to support any parts printed on top of it.

A potential alternative might be the "padding" of unprinted areas with some kind of powder before proceeding to the next layer, where the powder could then act as a support for the new print-out.

Events

From Feb. 10 to Feb. 14, 2009, the FTIStrap has been presented on the "didacta 2009" fair in Hannover, Germany - the author had been kindly invited by the "LPE Naturwissenschaft & Technik GmbH" (see http://www.naturwissenschaftundtechnik.de). More than 400 visitors came to see the FTIStrap in action and learn about the underlying technology (and the RepRap project). Quite a few of them already announced to build their own copy of this model - let's see how many will actually do so.

Here are a few pictures taken during the fair

Future Plans

As usual, the author's activities suffer from his very limited time. For that reason, it is rather unlikely that it will be before 2009 that the FTIStrap takes the next step - the handling of overhangs (in any way). Currently, the author prefers the padding of unprinted areas with powder, but it is completely unclear if such an approach can be successful with hot-glue as print material.

Configuration File Format

The FTIStrap Driver saves several settings (and the results of a calibration run) in a "configuration file" which can be (manually or automatically) loaded prior to the first print after starting the driver. Currently, however, the file contains more information than can be entered through the Controller Application. Thus, it might be necessary to edit the file manually - here is its format:

(tbd)

References

- [1] RepRap - "Wealth without money..."

- (see http://www.reprap.org)

- [2] RepStrap - A Bootstrap RepRap machine

- (see http://www.reprap.org/bin/view/Main/RepStrap)

- [3] fischertechnik - Bausteine fürs Leben

- (see http://www.fischertechnik.de)

- [4] Knobloch GmbH - Wenn es um fischertechnik, Lehrmittel, Computer und Elektronik geht

- (see http://www.knobloch-gmbh.de/)

- [5] fischertechnik designer

- (see http://www.fischertechnik-designer.de/)

- [6] LPE Naturwissenschaft und Technik GmbH

- (see http://www.naturwissenschaftundtechnik.de/)