ExtruderMechanicalParts

Contents

Making the non-rapid-prototyped mechanical parts for the extruder

Introduction

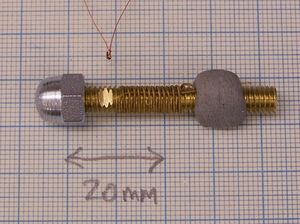

There are two main mechanical parts to the extruder: the heated barrel, and the drive screw and its bearings. This page tells you how to make both. The parts of the heated barrel are the PTFE cylinder, the dome nut, and the brass studding on the left. The drive screw is the silvery threaded rod on the right of the picture, with its brass half-bearings shown under it.

The .dxf engineering drawing files for the parts are in the attachments at the bottom of the page. These were created using Qcad.

The drive screw and its bearings

The drive screw

This should be made from M5 steel studding. It consists of a 70mm length of this with two 3mm diameter bearing lands turned on it. At the top end is a 3mm hole in which is soldered a 40mm length of 3mm braided steel wire. At the other end of the wire is a 5mm length of the studding with a nut soldered to it. This engages with the motor drive.

Start by cutting the 40 mm length of 3mm braided steel wire. The steel in this is hard, and is also easy to damage if you use a shearing cutting device. By far the best way to cut it is with a cutting disc in a mini-drill as in the picture.

Gently offer each end of the wire up to the flat of the cutting disk and rotate it between your fingers to grind a slight cone shape on either end:

This will make it much easier to solder the wire when the time comes.

Next make the drive screw. This is most easily done in a lathe, but Vik has an alternative that is described here.

This is the drawing of the two parts that you will make:

Cut an 80mm length of M5 studding. Start by drilling the 3mm hole in one end using a drill in the tail stock (don't forget to use a centre drill to get the alignment right first). Drill the 3mm hole deep enough so that you can remove the short 5mm length shown floating on the right with a parting-off tool and still have enough left for the main screw. Use coolant/lubricant while turning, and drill the hole with a woodpecker cycle (that is, withdraw the bit after cutting every few mm to clear the swarf).

After you have parted off the 5mm section, turn the length of the remaining studding down to 70mm. Clean any burrs from the drilled holes by twisting a larger diameter drill in them. Check that a nut will still screw cleanly onto the ends of the threads and, if necessary, clean them up too.

Next turn down the bearing lands. These need to be 3mm in diameter. This will probably be easiest if you turn the job round in the lathe chuck so that you always have a the shortest possible length projecting.

Now to solder the assembly together. Make sure all the parts to be soldered are clean of oxide and grease and coolant oil (wipe with methanol - methylated spirit - to clean off any grease). If you have a compressed-air line you can blow the parts clean too. It also helps to solder the parts just after you have turned and ground them - that way there is little time for an oxide film to build up on their surface. Even finger grease can cause trouble - try not to touch the bits that you are going to solder; cleanliness is everything.

Put a small quantity of flux (from plumber's suppliers) on the two cone ends of the wire, and inside the 3mm holes in the drive and the 5mm length of drilled studding. Be vary sparing in your use of flux; too much will make a real mess and - more seriously - cause solder to go where you don't want it to.

Push the cone-ends of the wire into the 3mm holes in the pieces of studding using a twisting motion in the direction that tightens the coils of the wire.

Put flux on the inside of an M5 nut, the screw it onto the 5mm studding length so it is flush with the end.

Hold the assembly in a vice or other suitable clamp (it's going to get hot) and use a small blow torch to heat the parts to be soldered. Start with the long studding and the wire inserted into it. Apply the heat gently - you only need to get the thing up to solder-melting temperature. If you make it too hot the solder will not join well; just after the flux starts to boil is the right temperature. Take the torch away from time to time and dab the end of a piece of solder on the join; when it just starts to melt, you're there. Feed a little solder into the join. If you put in too much it will soak up the coils of the wire and set it rigid. As the whole point of the wire is to form a flexible drive, this would be bad.

Next solder the 5mm studding length to the other end of the wire, and solder the nut to the studding. Everything should already be hot, so you should need less time with the blow torch here.

When the whole thing if cold, file off any excess solder from the top of the nut to bring it back flat. Wipe away any excess flux. Check that the wire still bends freely.

The half bearings

Now for the half-bearings. These are made of brass, but Vik has an alternative described here using washers which may be easier to make. Here is the drawing:

Drill a 3mm hole down a length of brass rod, then turn it down to 10mm diameter. Part off two 6mm lengths. Cut these just over half way with a hacksaw, then finish them down to half-round with a file. You may be tempted to make just one whole bearing and then to cut it in half. Be warned: unless you own a hacksaw with a 10 micron thick blade supplied by alien technology you will not be able to make this work...

Use the file to remove any burrs on the finished parts.

The heated barrel

This consists of a length of PTFE rod with a 3mm hole drilled down it. The end is drilled and tapped M6, and into that is screwed the barrel, which has a heating coil wrapped round it. On the end of that is a dome nut ("acorn nut" in some parts of the world) with a small hole that forms the extrusion orifice. The dome nut also has a thermistor glued into it for measuring the temperature.

Materials

You can make the barrel and the nozzle from three possible materials: steel, brass, or aluminium. These all have advantages and disadvantages:

- Steel: advantages - cheap, widely available; disadvantages hard to machine, low thermal conductivity;

- Brass: advantages - high conductivity, easy to machine; disadvantages copper in it may react slightly with polycaprolactone polymer;

- Aluminium: advantages - high conductivity, easy to machine; disadvantages not very strong (not a serious problem - the parts are not highly stressed in operation).

The choice is up to you and what you can obtain.

The PTFE holder

Make this from 16mm diameter PTFE rod. Cut a length of this slightly too long, and face it off in the lathe to get it the right length.

Drill the 3mm hole right through, then drill and tap the M6 hole.

To align the M6 tap, switch the power off to the lathe and put the tap in the tailstock. Release the tailstock so it is free to slide on the bed, then push the tap into the PTFE while turning the chuck by hand. Use a bottoming tap, not a taper one. Rotate the chuck clockwise by one turn, then back half a turn to clear the swarf. You should be able to feel when the tap reaches the bottom of the hole.

Turn the work round in the chuck, then touch a large-diameter drill on the 3mm hole just to make a small conical widening of it. Take care here - the drill will bite into the PTFE and go too deep unless you are very gentle.

Make sure the part is clean, with no loose or partly-attached bits of swarf. Any dirt left will get dragged down by the melting polymer and block the fine nozzle.

The brass barrel

There is a slightly modified alternative to this at the end of this page. It has both advantages and disadvantages. Take a look before deciding which to build.

Simply drill a 3mm hole right through a 38mm length of M6 studding. Drill the hole with a woodpecker cycle (that is, withdraw the bit after cutting every few mm to clear the swarf). Once again, remove any burrs and clean away all swarf scrupulously.

Next, cut an 8 ohm length of insulated 0.2mm nichrome wire. With that diameter the length for 8 ohms will be about 200mm, but the resistance is more important than the length, so cut to get the 8 ohms, not the 200mm.

Screw the PTFE, the barrel, and the dome nut together lightly by hand and mark on the barrel where the other two parts come to using a felt pen.

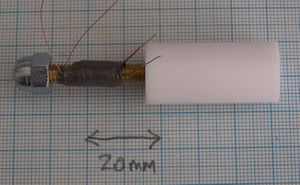

Wrap the wire into the thread as shown in the picture, leaving the wire ends free (about 20 mm lengths) and securing them with Blu-tack or sticky tape. Make sure that the winding is clear of where the PTFE and the dome nut will go. The free ends of the nichrome should be at the PTFE end:

Mix up some JB Weld high-temperature epoxy glue and apply it carefully to the coil (note - the next section also needs a little JB Weld. You may care to read that first before gluing this part so that you can set both up, glue them at the same time, and so only mix up one portion of glue):

That picture shows the result when the glue has set - obviously the barrel will have to be held by one end to keep the setting glue clear of other objects and surfaces while the glue is being applied and is setting.

Leave the glue to set for 24 hours.

But They Don't Sell JB Weld Here

If No JB Weld is available, obtain a can of black BBQ paint such as Dulux Spraykote. These silicone-based enamels are good up to 650C, but need to be dried and heated to approximately 250C to fire the enamel. Apply 3 coats under the coil, and 4 coats over the coil. A hair-dryer will speed drying and an oven or (for a really quick firing) blowtorch can be used for the final curing.

The dome-nut nozzle.

These instructions assume that you're making an 0.5mm nozzle, but you can substitute other drill diameters easily to make other sizes.

Drill a hole for the thermistor in the side of the nut just slightly larger in diameter than the thermistor you will use. With the standard one from the parts list this means a hole 1.5 mm in diameter (the thermistor is 1.3 mm). Use a centre-punch to position the start of the hole in the centre of one of the nut's hexagon of faces. Take care that the drilled hole does not go right through to the thread.

Next turn the nut round and drill an 0.5 mm hole through the tip from the back to form the nozzle. Take care here - an 0.5mm drill is very easily broken.

Stick the dome nut to the bench with Blu-tack and place the thermistor in the side hole, holding it by one of its wires to keep it in place. Take care that neither of the wires touch the metal of the dome nut.

Take the thermistor and whatever you use to hold it away. Put a little mixed JB Weld high-temperature epoxy glue in the hole with a sharp instrument (a sewing needle or pin works well). Put the thermistor back, again taking care to ensure that the leads do not touch the metal of the nut.

Back-fill the hole with a little more JB Weld glue and clean any excess from the area surrounding it.

Leave the glue to set for 24 hours.

Final assembly and wiring

Do a final thorough clean of all three components - any dirt in them will block the nozzle.

Screw the three components together. Put a little PTFE plumber's tape between the barrel and the nozzle to seal it (the white tape in the picture).

Do the assembly up by hand - there is no need to use spanners and pliers; a solid, firm, hand-tight fit is all that is needed.

Strip the insulation from the last 10mm of the ends of the nichrome wire. The insulation is glass fibre, so the easiest way to do this is to scrape it with a sharp blade at right angles to the wire.

Now to solder up the connections. Cut a 210mm length of thin 4-way ribbon cable. Split this into two pairs for about the last 40 mm. Split the ends of the pairs to make a couple of snake tongues.

Strip the insulation back by 5mm on one pair (the thermistor) and 10 mm on the other (the nichrome heater). Tin all four ends with solder.

Now here's a problem. Solder won't wet nichrome. However, if you take a short length of stiff wire (a lead cut from a resistor or capacitor works well) you can twist the ends of the nichrome and the ends of the ribbon cable round that and solder the lot - this seems to make a good join. Insulate the join with heat-shrink sleeve.

The short pieces of nichrome get hot in operation, so keep them flying free (that is, don't fold them tight against the barrel or the PTFE).

Cut the ends of the thermistor wires to about 5mm and tin them. Thread short lengths of heat shrink onto the ends of the ribbon cable, solder the ends to the thermistor, then slide the heatshrink down and shrink it.

Attach the ribbon cable to the PTFE rod with a cable tie as shown. Pull the tie as tight as possible.

Finally split the other end of the ribbon cable back about 50mm and put two 2.54 mm 2-way sockets on it.

Use a multimeter to check that the resistance of the coil is about 8 ohms, that the resistance of the thermistor is about 10K (or the appropriate value if you have chosen a different thermistor) and that neither are shorted to the barrel nor to the dome nut.

Alternative barrel design

There is a slightly different way of making the barrel (and nozzle) that has both advantages and disadvantages over the version above. You make the barrel longer (45 mm instead of 38 mm) and file a notch in it between the nichrome coil and the dome-nut nozzle to glue the thermistor in. File the notch with a small rat-tail file taking care not to go all the way through to the 3 mm hole...

Advantages:

- You can swap the dome-nut nozzle easily

- All the JB-weld gluing is in one place

Disadvantages:

- Slightly longer, therefore less rigid and more bulky

- Thermistor may read high as it's too close to the coil

The second disadvantage is not really one, as that can be overcome by calibration. And I think that the ease with which the dome-nut can be swapped and the device cleaned out outweighs the disadvantages.

-- Main.AdrianBowyer - 06 May 2007