Exquisite Automated Build Platform

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

These are good resources for creating wiki pages. Very Messy Example and Columbus --Sebastien Bailard 07:23, 10 September 2010 (UTC)

Release status: unknown

| Description | documenting a generic tool/artpiece

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

One wiki editor has suggested renaming this page to conveyor belt build platform.

mendel abs (automatic build platform generic)

this is an attempt to make an automatic build platform for Mendel.

the idea, is to have a unit bolt onto the frog assembly no larger than 15mm in height, that uses a geared motor to move a belt of polyimide film around every so often to clear parts.

i will be uploading picture of my unit, and diagrams and how to make and machine and possibly print parts for it. note. my unit does not yet work. it does not yet have safety features.

7 essentials of design: 1) must not be two high as to prevent large objects from being built

2) must not be heavy as to slow down y movement and acceleration by more that 10%

3) absolutely must have a flat surface, and be designed sturdy enough to print for 100hrs without warping or adjustment

4) must allow printing of base layer without raft at a minimum of 34mm/s at least for 0.6mm nozzles.

5) must have a built in fail safe so as to not over temp. (fusible linkage, some mechanical fail safe that works no matter what fails)-

6) must be tested by at least another member in the community.

7) must be easy to transport and assemble.

background. this has been talked about for some time on the reprap forum, although i would like credit for implementing this version, prior credit goes to other people. i will do a search and add those names later.

I also am documenting this here, so it remains a public document, and can serve of proof of prior concept.

how it works:

heater is possibly copper spreader and 2 8ohm resisters 20 watts each in series or parallel to 24v (halogen bulb did not transfer more than 6% of energy to board as heat.

inside there will be wooden structures that support and keep surface from flexing. nylon spacers will be used in front and back for low friction movement of 5/16" (8 mm) rods about 10 inches wide, with polyvinyl tubing to allow it to have grip.

fusible linkage will be hooked up in series to lamp, and will be mounted and kapton taped to bottom surface.

side supports to bolt into the frog of regular Mendel bolt holes. side supports are made of wood because of low warping at high temp. rest are pocket for build surface will be slightly oversize, and gripped from the front inside, with rubber. allowing glass ore backside of copper clad board to expand freely.

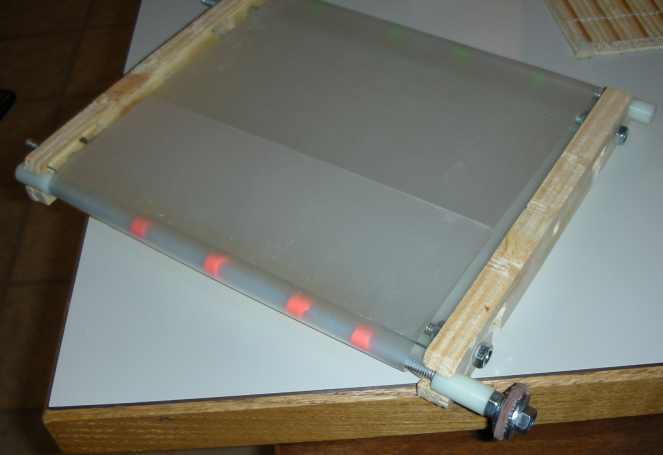

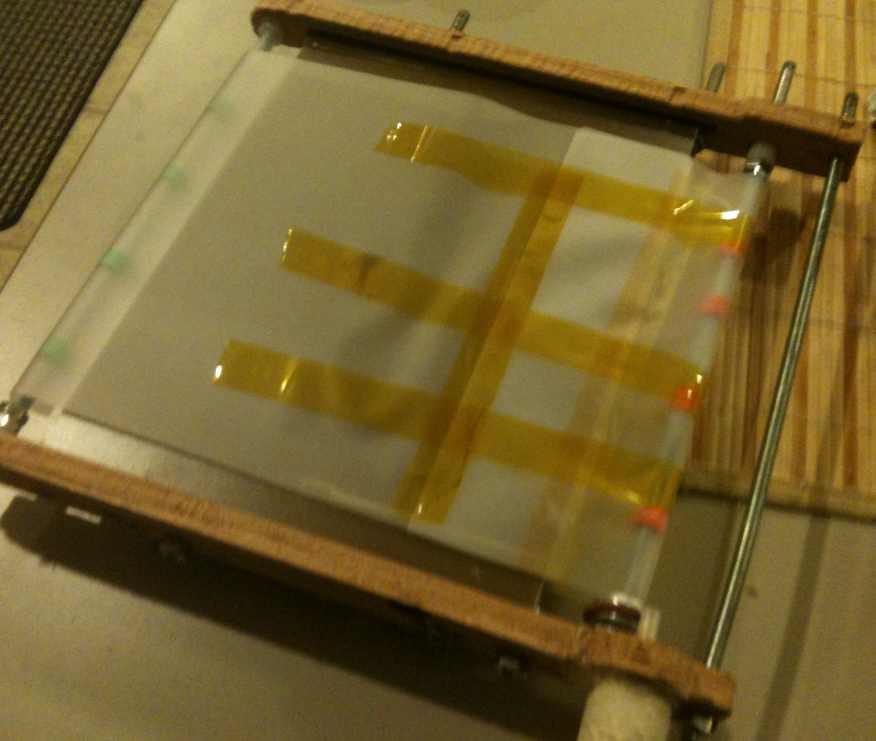

here is a picture below of what i have currently

7th design looks like this:

video proof of concept: (basically looks good but does nothing much) <videoflash>yDXkF8dsqMk</videoflash>

video motor working here: (heater is off, plastic is not really secured, and motor is not gear meshed to pull system, yet. Still i found my motor!) <videoflash>s0nOJtCovLk</videoflash>

video of vacuum test research: (simple but shows results)

<videoflash>Ly2f3kWg9I8</videoflash>

video demonstrating vacuum pull without airtight container. - shows it may work. not that it actually will. we will see here soon enough.... some errors: i said a few motors, should have said a few batteries.... one of the side effects of doing a video at 3amish... <videoflash>dc8Aq9S-rLU</videoflash>

1/17 - since this is an abp for mendel, i decided this weekend to build an actual standard Ed Sell Mendel. it took 2 days to print the parts, and to machine the frog and base plate. still need to do some work with motors and belts. will use custom electronics. here is the mendel video, showing also the abp. it will be designed to work on the standard mendel.

<videoflash>oCQv721QPEs</videoflash>

1/10/2011

so far i have been finding some free time i to make it work. i have been thru 7 designs variations, and have decided that heat lamp does not transfer enough energy to the surface. i can easily design a heated platform by etching a board, but this is not cost effective. i will try to make a regular pcb sheet with copper be able to be used. i also had to redesign the outside front a little bit to get the 15mm or less height. the height is now at approx 15mm for platform. but it is 2 inches wider. i will update again by this sunday, hopefully with a version that can be laser cut.

here is version 1 stl files:

if you have a cnc 3 axis and have wood handy. these files are in inches. the wood i used was .66 inch thick. it will change, already i am preparing for laser cut version. still investigating Poly(methyl methacrylate) it apparently melts between 85deg and 180deg c that is too low for a bed that can go up to 150c, although that leaves some room for it as a linkage switch.

www.profounddevices.com/abp/roller3b.stl

www.profounddevices.com/abp/sideroller.stl

here is another video showing the motor i am going to ue that is powerful enough. it is going to be a gear mesh later on so it will not use traction, and the motor will be on the inside not the outside, also a slide tray will be in front.

video here: http://www.youtube.com/watch?v=s0nOJtCovLk